Fixed rotary type soot blower for large-size power station boiler furnace arch

A power plant boiler and flame angle technology, which is applied in the field of boiler soot blowers, can solve the problems of being unable to approach the slope surface, affecting the heat absorption of the heating surface, and unsatisfactory soot blowing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

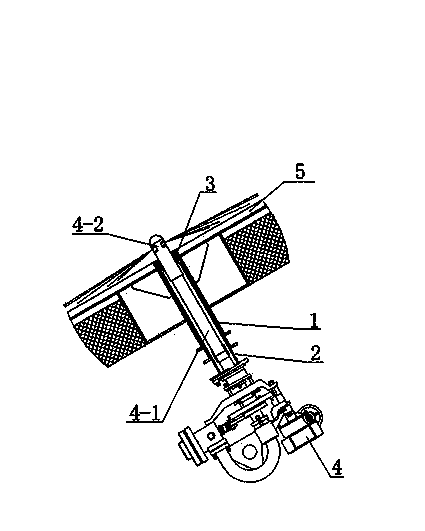

[0007] Such as figure 1 As shown, the present invention is composed of an outer sleeve 1, an inner sleeve 2, a sealing ring 3 and a fixed rotary soot blower 4, and a mounting hole for the outer sleeve 1 is opened on the slope surface 5 perpendicular to the boiler flame angle, and the outer sleeve The sleeve 1 is installed in the installation hole of the outer sleeve 1 on the slope surface 5, and one end of the outer sleeve 1 is located on the same level as the slope surface 5, and the two ends of the outer sleeve 1 are the installation holes of the inner sleeve and the fixed rotary blower respectively. The installation hole of the soot blowing barrel of the ash device 4, the sealing ring 3 is installed at the inner sleeve installation hole of the outer sleeve 1, the inner sleeve 2 is installed in the outer sleeve 1, and one end is against the sealing ring 3, the fixed rotary The soot blowing barrel 4-1 of the soot blower 4 is installed in the inner sleeve 2, the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com