Vacuumizing lid rotating device of hard bottle

A vacuum pumping and bottle body technology, which is applied in the direction of packaging and packaging under vacuum/special atmosphere, can solve the problems that the sealing ring and the bottle body cannot be completely fitted, the production efficiency of the capping machine is low, and the energy consumption is large, so as to eliminate If the pressure is too small, the vacuum chamber is not completely sealed, which prevents the bottle from being damaged by fracturing and shortens the time for vacuuming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

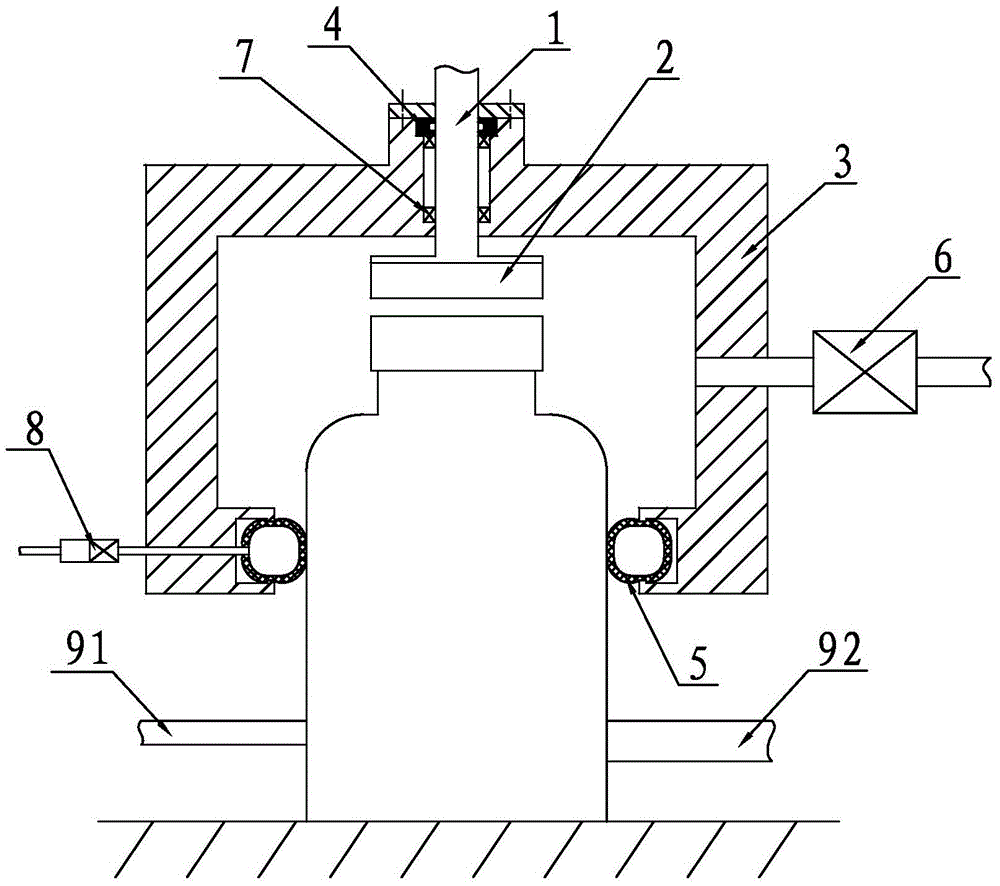

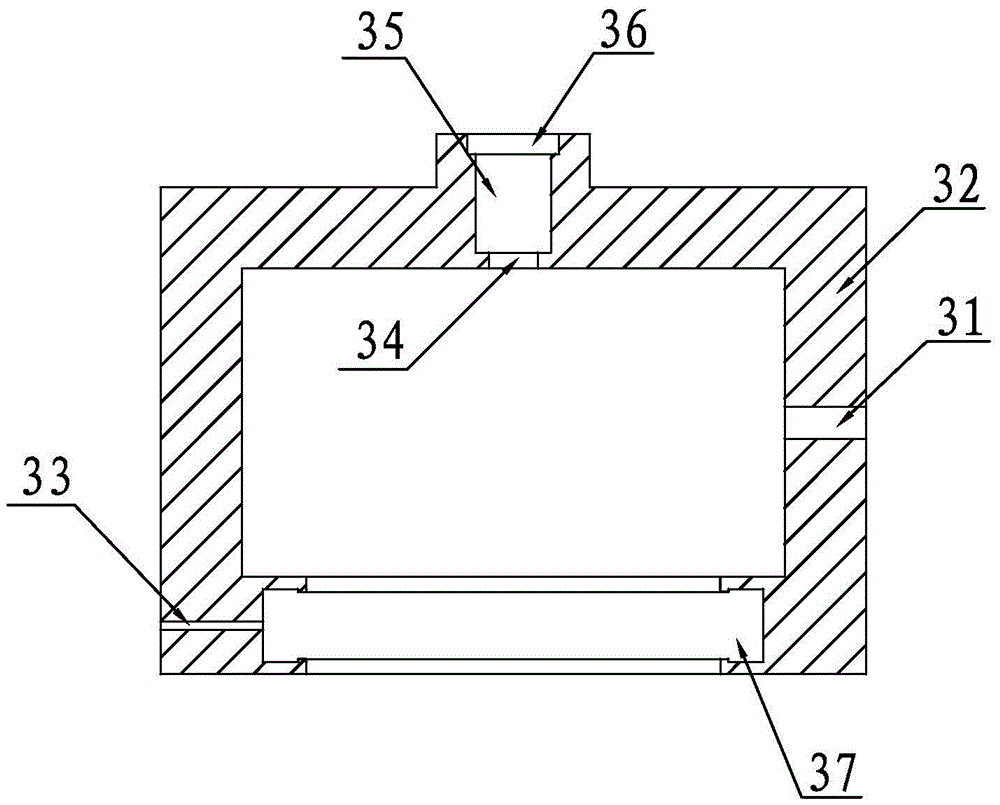

[0026] Embodiment 1: a kind of hard bottle body vacuum capping device, such as Figure 1 ~ Figure 2As shown, it includes a capping shaft 1, a capping head 2, a vacuum cover 3, a main shaft sealing ring 4, an inflatable clamping sealing ring 5, a vacuum switching valve 6 and a bearing 7. The vacuum cover 3 includes a vacuum interface 31, a cylinder 32. Air guide port 33, shaft hole 34, bearing hole 35, spindle sealing ring installation hole 36 and inflatable sealing ring installation groove 37, vacuum interface 31 is set above the inflatable clamping sealing ring 5, and is connected with the inside of the vacuum cover 3 The cavities are connected, the vacuum interface 31 is connected with the vacuum device through the vacuum switch valve 6, the cylinder body 32 is a cup-shaped body with an open lower end, and the shaft hole 34, the bearing hole 35 and the spindle sealing ring installation hole 36 are all set in the cylinder body. 32, the bearing 7 is installed in the bearing ho...

Embodiment 2

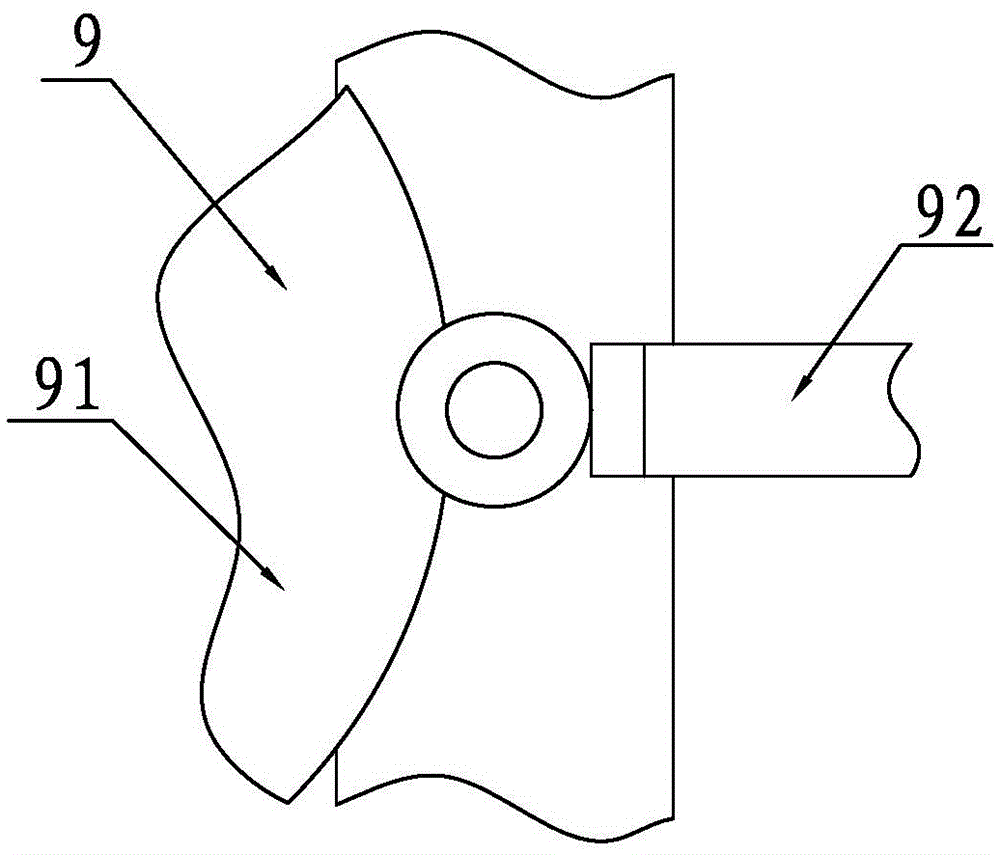

[0027] Embodiment 2: The difference from Embodiment 1 is that, as image 3 As shown, the bottle body clamping structure 9 is also included, and the bottle body clamping structure 9 is arranged between the workbench and the vacuum cover 3, and it is composed of a bottle dial 91 and a bottle pressing block 92. Evenly set the bottle pulling grooves to accommodate the bottle body. When the bottle body is transferred from the bottle dial 91 to the station to be capped, the bottle pressing block 92 moves to the direction of the bottle dial 91 to press the bottle body under the action of the driving mechanism. , so that the bottle body to be capped is fixed relative to the vacuum cover 3, and the air-filled clamping sealing ring 5 only realizes sealing and coating on the bottle body, and the sealing pressure can be reduced, so that the clamping and sealing of the bottle body can be realized. , can thoroughly eradicate the defects existing in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com