Gasket sleeve and gasket assembly for a fireproof lock

A gasket and lock technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems of poor sealing, poor fire resistance, and no mention of fire and smoke insulation of locks, and achieve high expansion shape retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

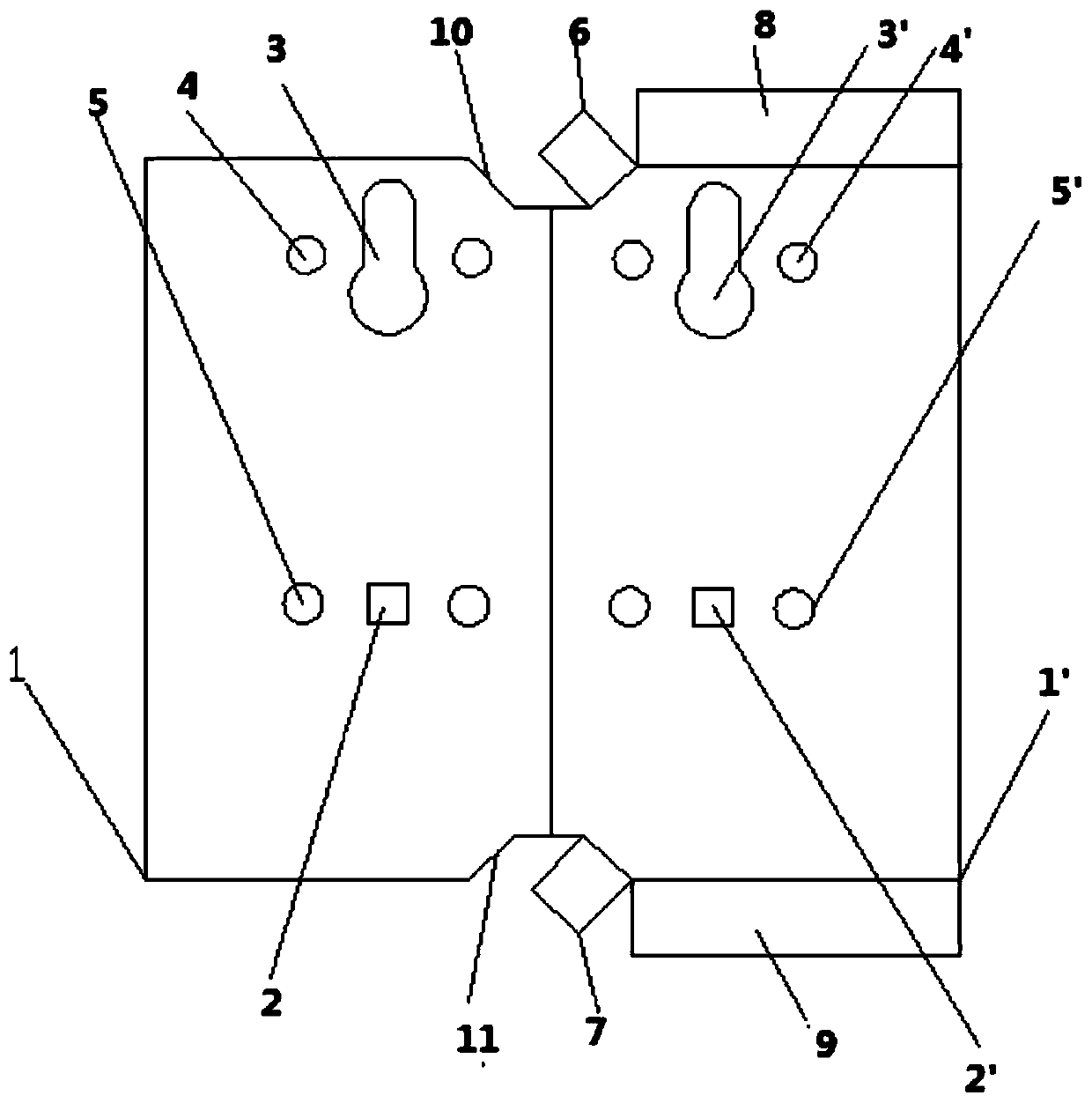

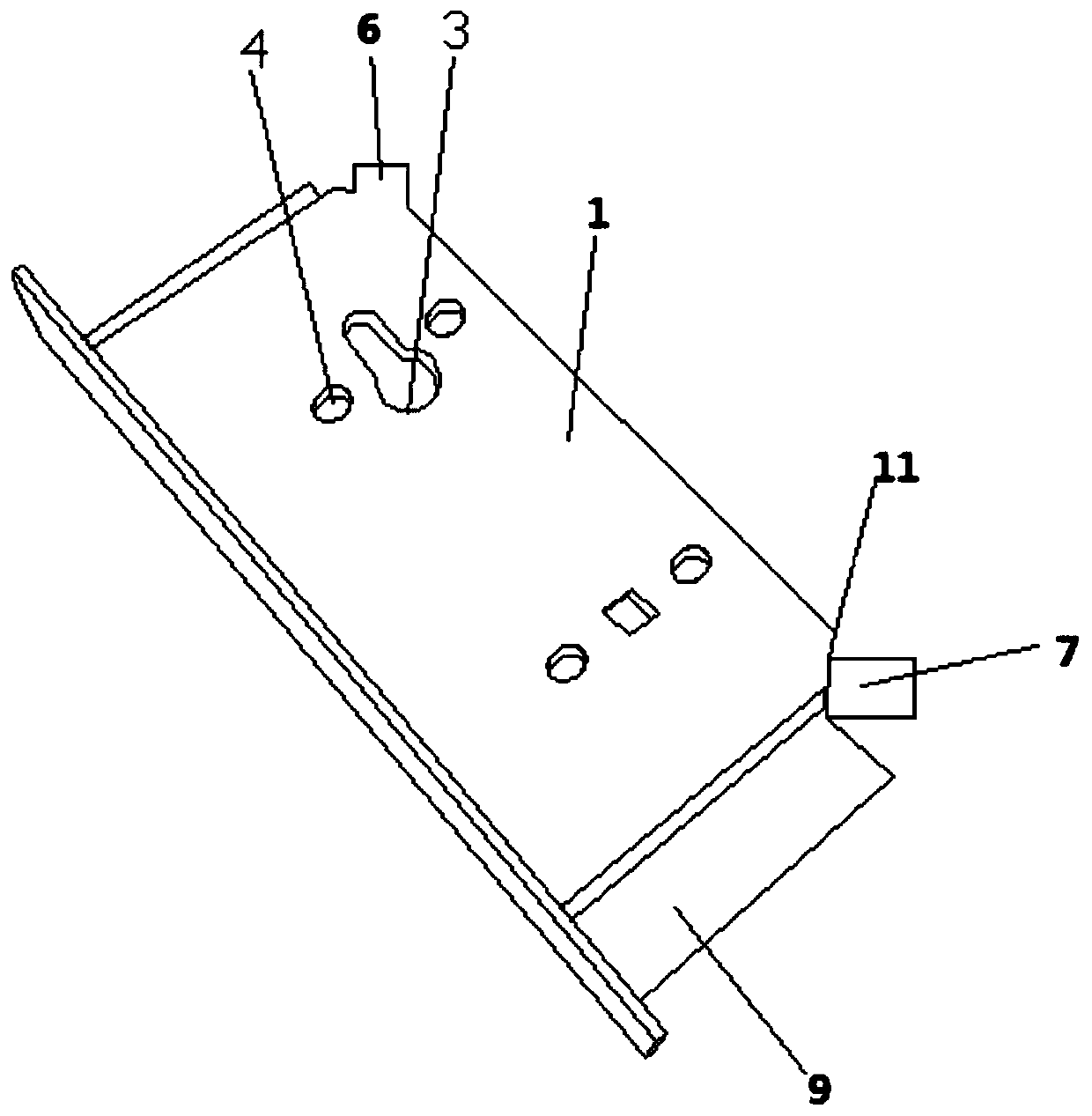

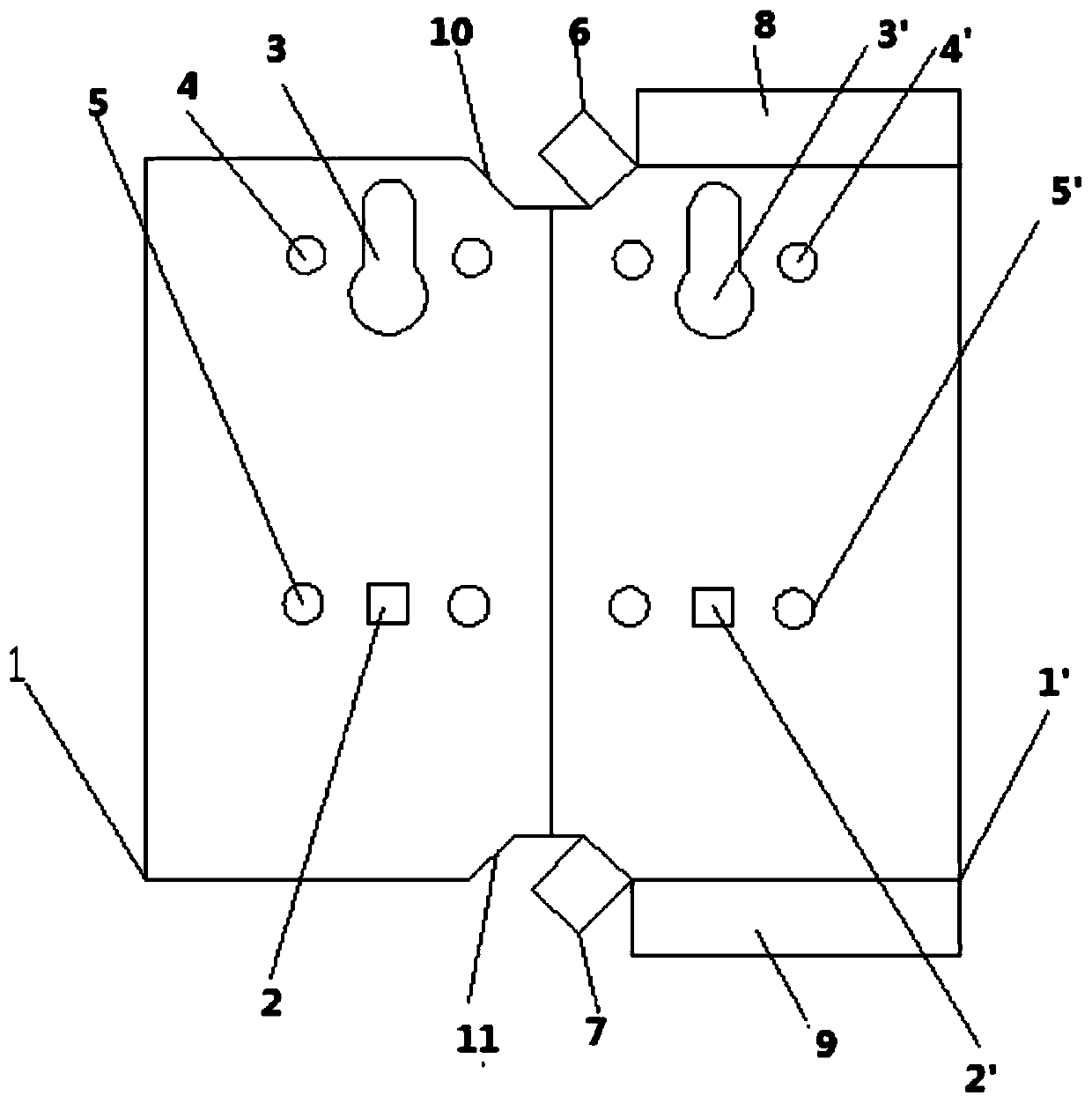

Image

Examples

Embodiment 1

[0025] Weigh the raw materials of the following parts by weight:

[0026]

[0027]

[0028] Mix the above raw materials, put them into an extrusion granulator to make a color masterbatch, then extrude, water-cool to make a sheet material, and then cut and punch to form the required gasket sleeve. The combustion performance and flexibility of the required gasket sleeve were tested, and the results are shown in Table 1.

Embodiment 2

[0030] Other conditions are the same as in Example 1, except that the polyethylene resin in Example 1 is replaced by polysiloxane resin.

Embodiment 3

[0032] Other conditions were the same as in Example 1, except that the treated white carbon black was replaced with white carbon black not treated with silane coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com