Aluminum alloy and production method thereof

An aluminum alloy and alloy liquid technology, applied in the field of alloys, can solve the problems of difficult to control harmful substances and impurities in aluminum alloys, difficult to accurately control the upper and lower limit elements, and a large range of element additions, and achieve good extrusion. performance, optimized mechanical properties, the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

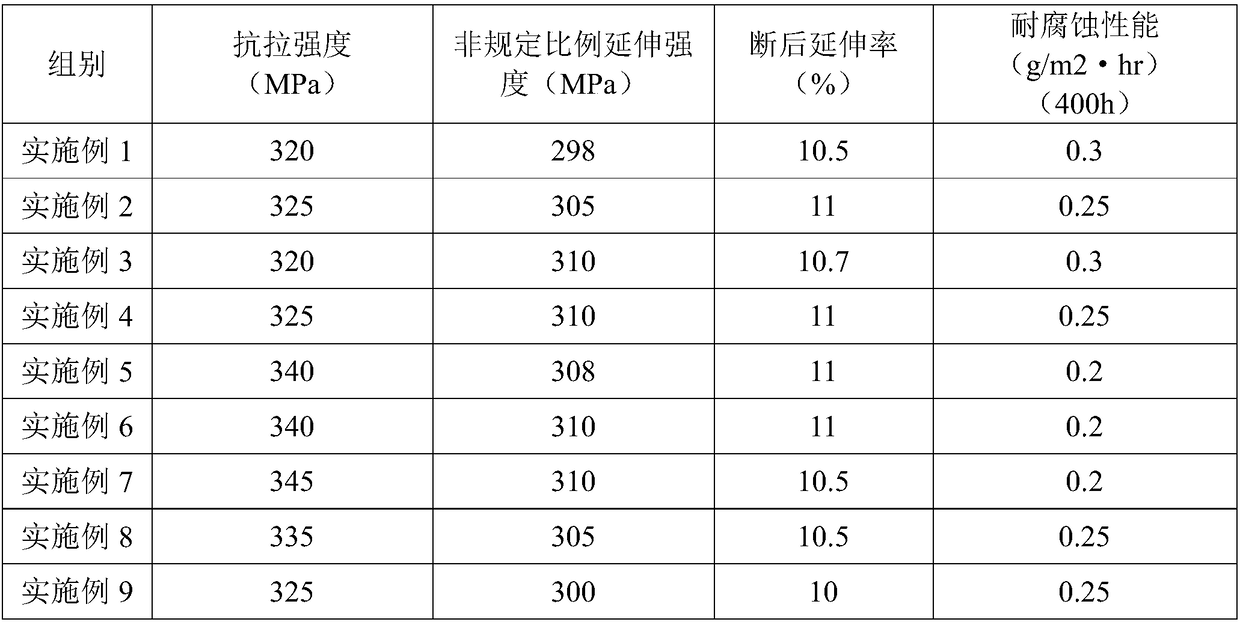

Examples

preparation example Construction

[0056] Correspondingly, the present invention also provides a method for preparing an aluminum alloy, comprising the following steps:

[0057] S1. Put the aluminum ingot into the casting furnace for melting, and the temperature in the furnace is 730-760°C;

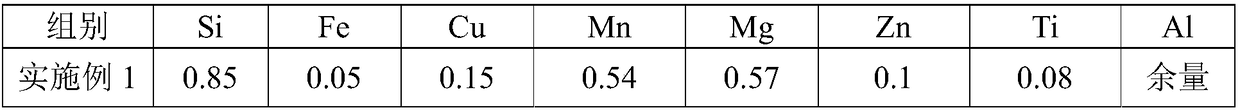

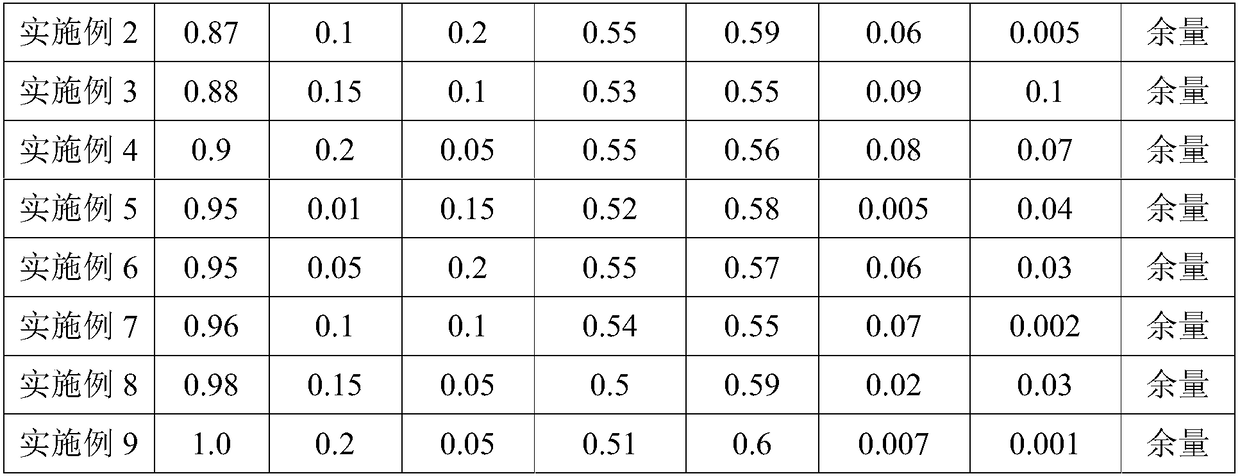

[0058] S2. Add the following raw materials into the casting furnace according to the ratio: 0.85-1.0wt% Si, greater than zero and less than or equal to 0.2wt% Fe, greater than zero and less than or equal to 0.05wt% Cu, 0.5-0.55wt% Mn, 0.55-0.6wt% of Mg, greater than zero and less than or equal to 0.1wt% of Zn, greater than zero and less than or equal to 0.1wt% of Ti, wherein the content of Al is the balance of the above components;

[0059] S3, carry out degassing treatment and refining, the refining temperature is 720-750 ° C, after refining, let it stand for 20-40 minutes to obtain alloy liquid;

[0060] S4, casting the alloy liquid into an aluminum alloy rod, wherein the casting speed is 85-95mm / min;

[0061] S5. Extr...

Embodiment 1

[0077] S1. Put the aluminum ingot into the casting furnace for melting, and the temperature in the furnace is 730°C;

[0078] S2, adding the following raw materials into the casting furnace: Si, Fe, Cu, Mn, Mg, Zn and Ti;

[0079] S3, carrying out nitrogen degassing and refining, the refining temperature is 720°C, and standing for 20 minutes after refining to obtain alloy liquid;

[0080] S4, casting the alloy liquid into an aluminum alloy rod, wherein the casting speed is 85mm / min;

[0081] S5, heating the aluminum alloy rod to 470°C, and heating the mold to 460°C;

[0082] S6. Put the ingot into the extrusion cylinder, and the extrusion rod of the extruder pushes the aluminum alloy ingot in the extrusion cylinder to extrude from the discharge port of the extrusion die to form an extruded profile. The temperature of the discharge port is 525 ℃;

[0083] S7. The extruded profile is pulled by the tractor after the discharge port, and the water mist quenching device is used f...

Embodiment 2

[0086] S1. Put the aluminum ingot into the casting furnace for melting, and the temperature in the furnace is 740°C;

[0087] S2, adding the following raw materials into the casting furnace: Si, Fe, Cu, Mn, Mg, Zn and Ti;

[0088] S3, carrying out nitrogen degassing and refining, the refining temperature is 730°C, and standing for 30 minutes after refining to obtain alloy liquid;

[0089] S4, casting the alloy liquid into an aluminum alloy rod, wherein the casting speed is 90mm / min;

[0090] S5, heating the aluminum alloy rod to 480°C, and heating the mold to 460°C;

[0091] S6. Put the ingot into the extrusion cylinder, and the extrusion rod of the extruder pushes the aluminum alloy ingot in the extrusion cylinder to extrude from the discharge port of the extrusion die to form an extruded profile. The temperature of the discharge port is 530 ℃;

[0092] S7. The extruded profile is pulled by the tractor after the discharge port, and the water mist quenching device is used f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com