Preparation method of ethylene propylene diene monomer based cable accessory material and ethylene propylene diene monomer based cable accessory material prepared by preparation method

A technology of EPDM rubber and cable accessories, applied in rubber insulators, organic insulators, etc., can solve the problems of restricting the rapid development of high-voltage DC cables, uneven distribution of electric field, breakdown failure of accessories, etc., and achieve stable DC breakdown electric field. Intensity, Improved Conductivity Gradient, Effect of Low Threshold Field Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] A preparation method of EPDM rubber-based cable accessory material, comprising the steps of:

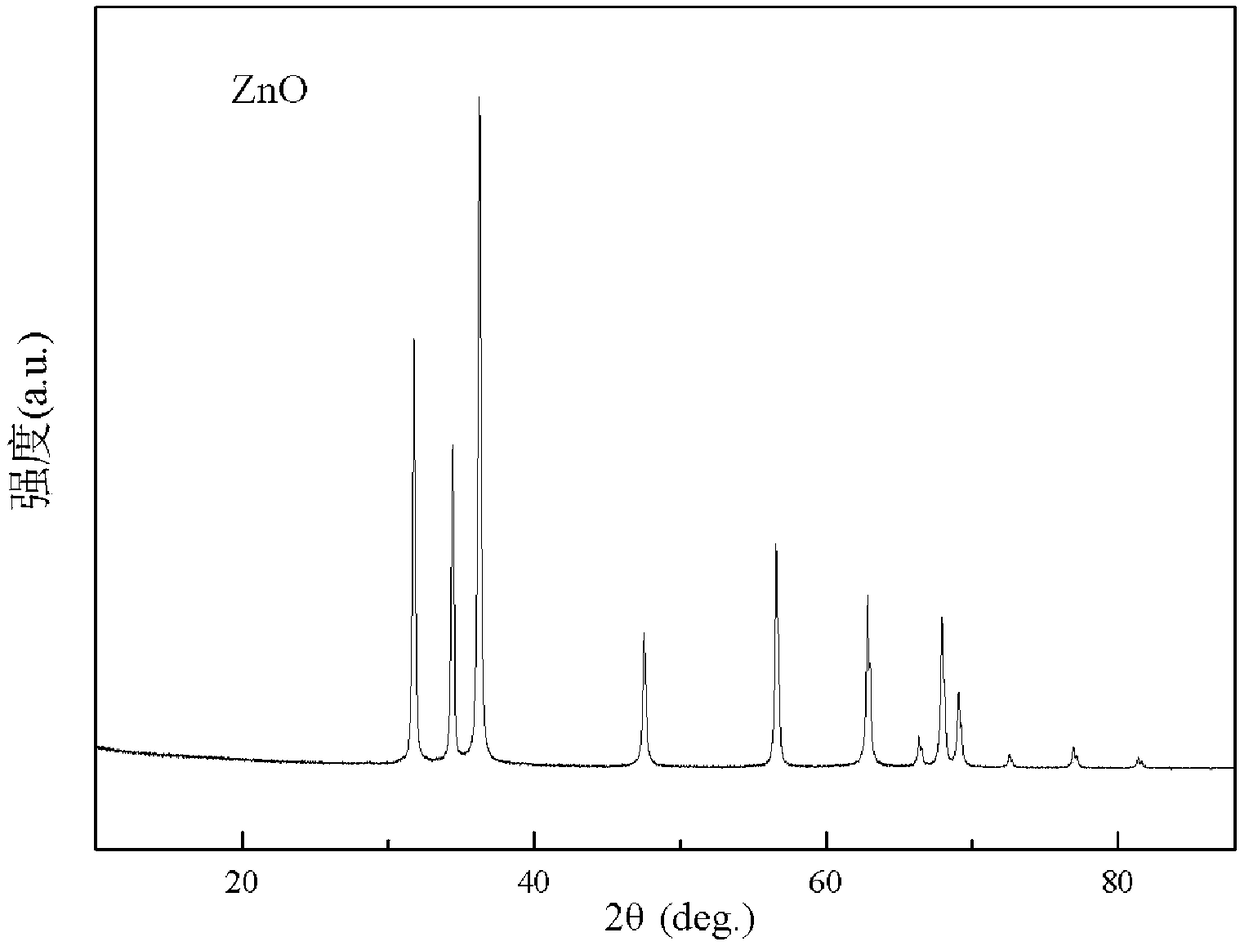

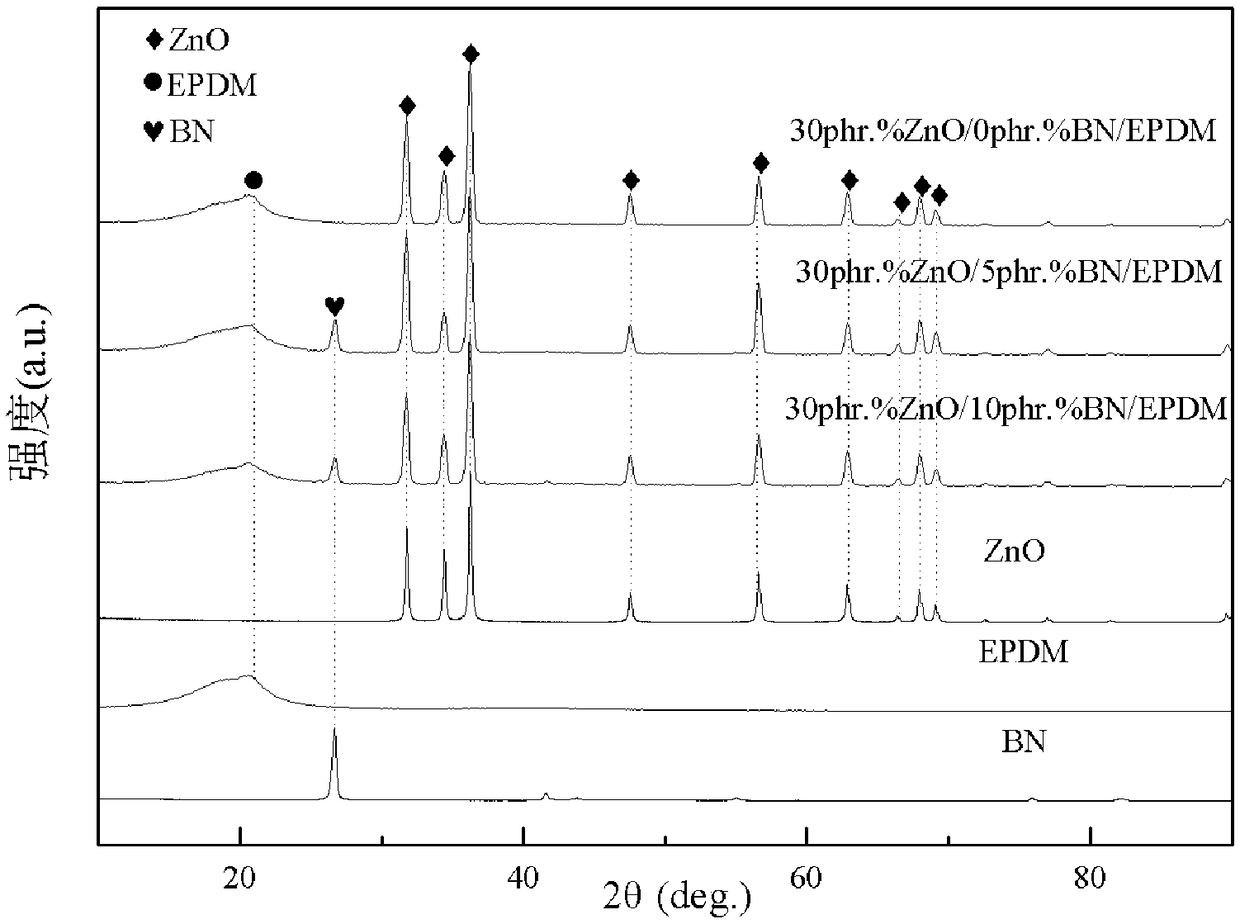

[0031] Step 1. Weigh zinc oxide, boron nitride, and deionized water according to a certain mass ratio, first put boron nitride into deionized water and stir, then put it into an ultrasonic disperser for ultrasonication, then add zinc oxide and continue stirring until Dissolve completely, and finally centrifuge the mixed solution with a centrifuge to obtain a mixed powder of zinc oxide and boron nitride, which is dried for use;

[0032] Step 2, placing the mixed powder obtained in step 1 in a ball mill, and after ball milling evenly, obtain zinc oxide and boron nitride ball mill powder for use;

[0033] Step 3, configuring a tris buffer solution with a concentration of 2 g / l, and then adjusting the pH of the tris buffer solution with dilute hydrochloric acid to be 8.5 to prepare a Tris-HCl buffer solution;

[0034] Step 4. Take the zinc oxide and boron nitride ball milling pow...

specific Embodiment approach 2

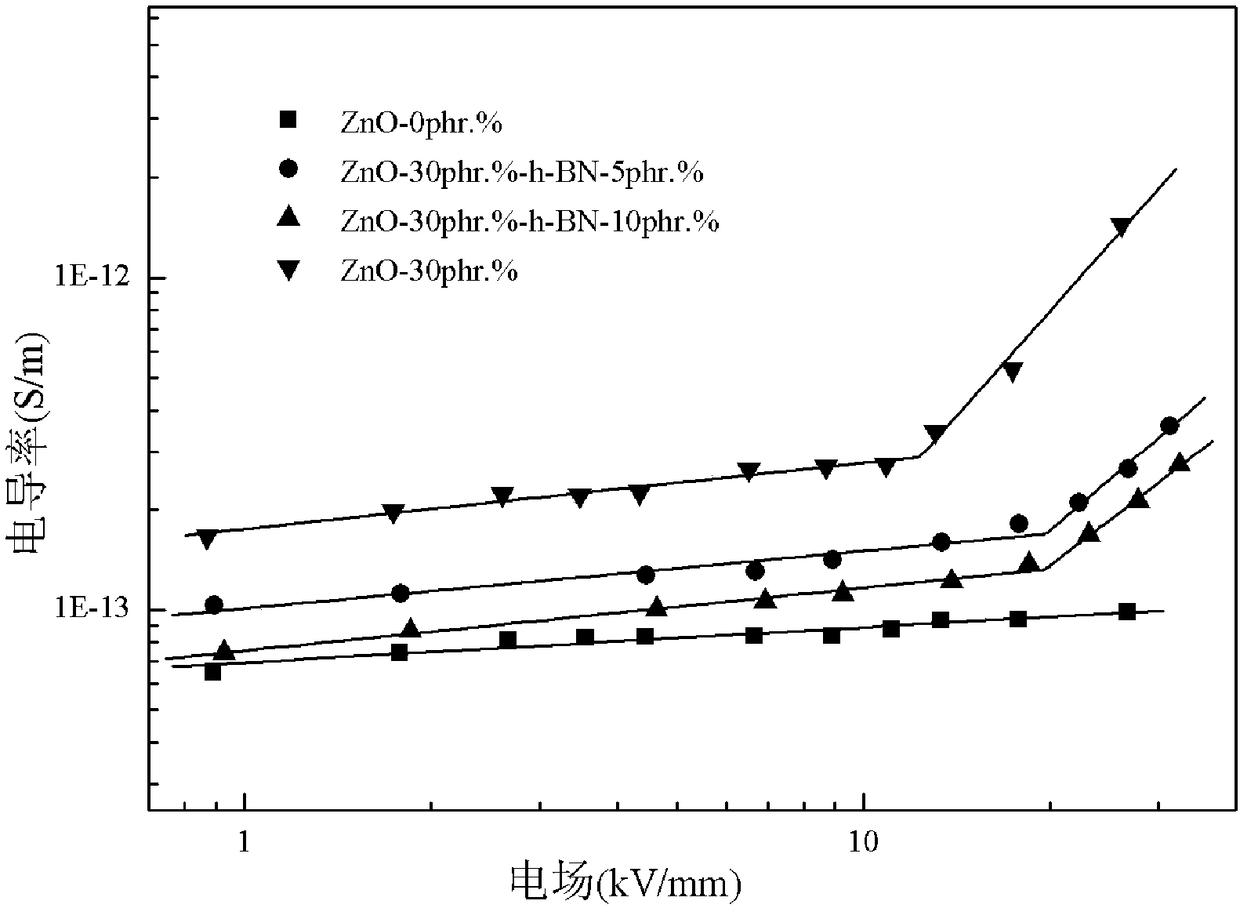

[0045] An EPDM rubber-based cable accessory material prepared according to the preparation method of an EPDM rubber-based cable accessory material described in Embodiment 1 has a breakdown strength of 80.72 kV / mm, and a nonlinear coefficient of It can reach 1.36, and the threshold field strength is 19.8kV / mm.

specific Embodiment approach 3

[0048] A preparation method of EPDM rubber-based cable accessory material, comprising the steps of:

[0049] Step 1. Weigh zinc oxide, boron nitride, and deionized water according to a certain mass ratio, first put boron nitride into deionized water and stir, then put it into an ultrasonic disperser for ultrasonication, then add zinc oxide and continue stirring until Dissolve completely, and finally centrifuge the mixed solution with a centrifuge to obtain a mixed powder of zinc oxide and boron nitride, which is dried for use;

[0050] Step 2, placing the mixed powder obtained in step 1 in a ball mill, and after ball milling evenly, obtain zinc oxide and boron nitride ball mill powder for use;

[0051] Step 3, configuring a tris buffer solution with a concentration of 2 g / l, and then adjusting the pH of the tris buffer solution with dilute hydrochloric acid to be 8.5 to prepare a Tris-HCl buffer solution;

[0052] Step 4. Take the zinc oxide and boron nitride ball milling pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com