A kind of silicone rubber-based DC cable accessory material and preparation method thereof

A DC cable, silicone rubber technology, applied in textiles, papermaking, fiber chemical characteristics, etc., can solve the problems of reducing the anti-breakdown performance of cable accessory materials, affecting the overall performance of cable accessory materials, etc., to reduce the probability of failure and improve electrical conductivity The effect of gradient, homogenized electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of a preparation method of a silicone rubber-based DC cable accessory material are as follows:

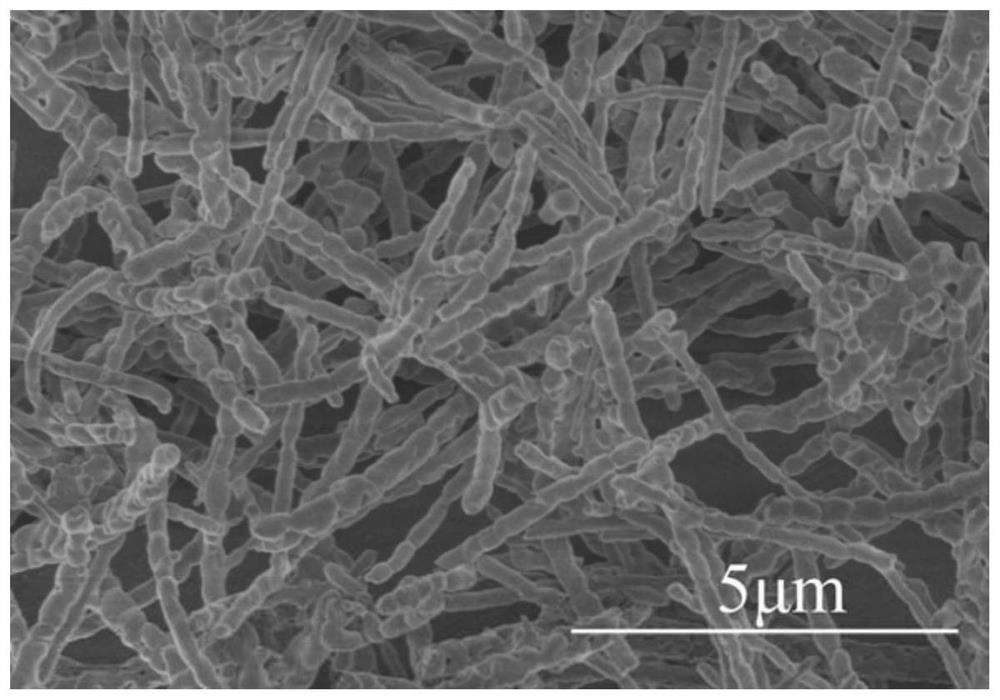

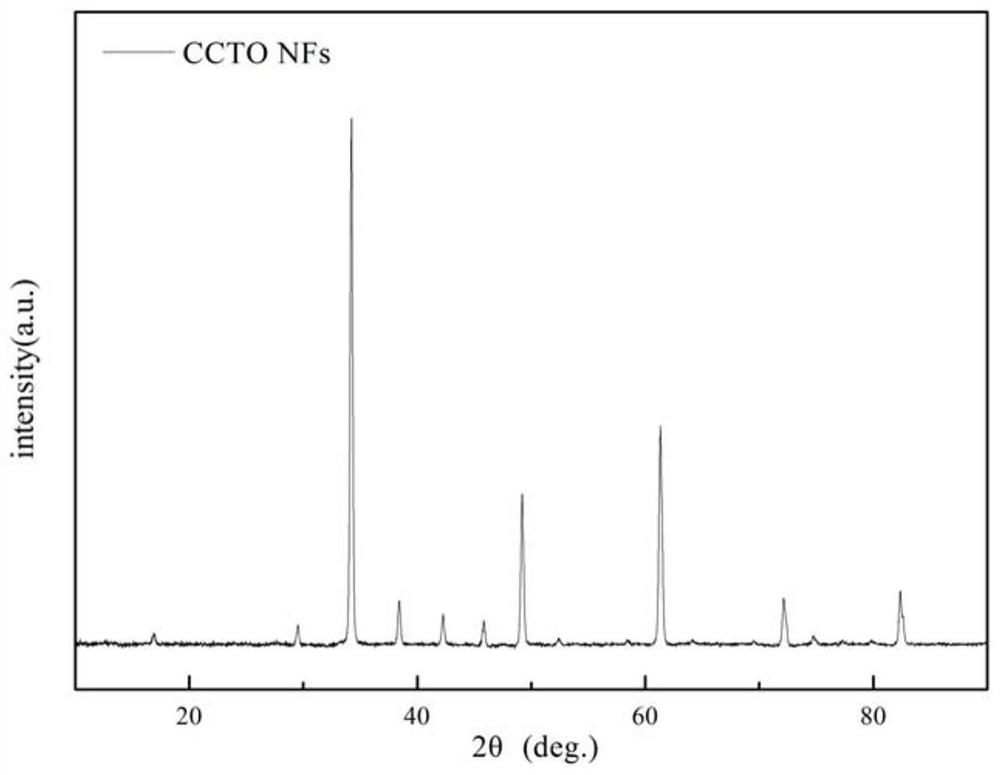

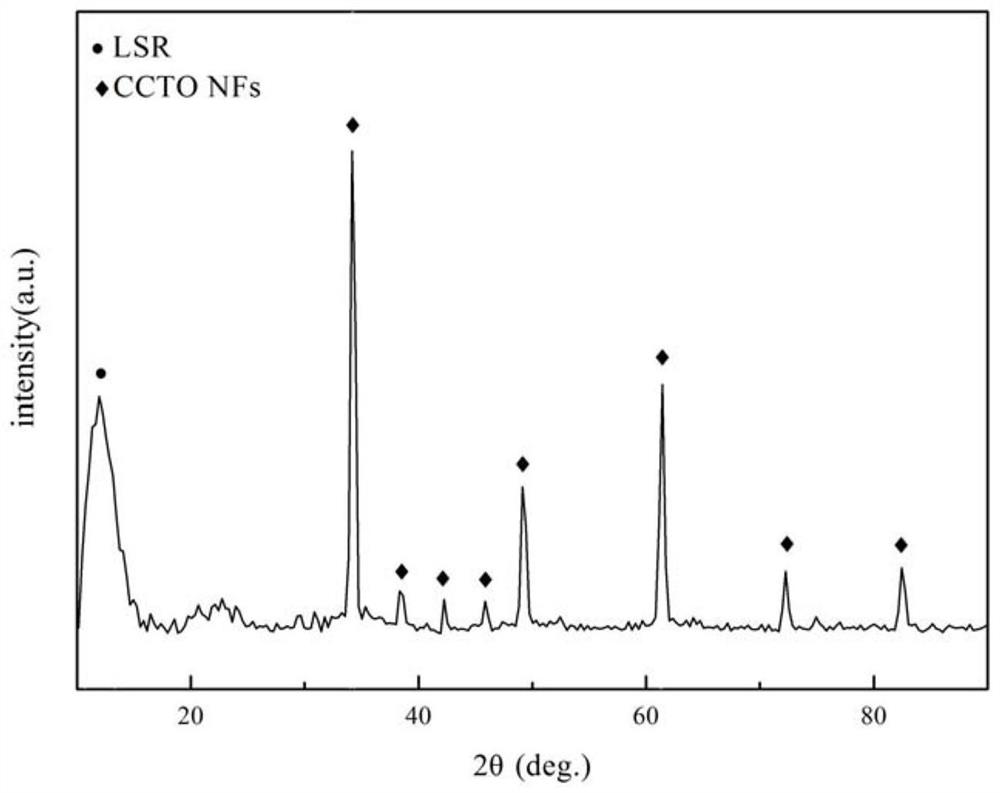

[0032] 1. Copper acetate monohydrate: calcium nitrate tetrahydrate: n-tetrabutyl titanate = 1:3:4 in molar ratio, and volume ratio according to the volume of n-tetrabutyl titanate: n-tetrabutyl titanate: anhydrous ethanol: Acetic acid=3:50:1, respectively measure 20ml absolute ethanol, 0.4ml acetic acid, 1.2ml n-tetrabutyl titanate, and respectively weigh 0.517g copper acetate monohydrate and 0.218g calcium nitrate tetrahydrate, mix absolute ethanol, The acetic acid is poured into the beaker in turn and stirred evenly, the copper acetate monohydrate is added to the above mixed solution and it is completely dissolved, and then calcium nitrate tetrahydrate is added to the mixed solution to completely dissolve the calcium nitrate tetrahydrate to obtain a clear mixed solution; Add n-tetrabutyl titanate to the clear mixed solution, and continue stirring for 40 minutes a...

Embodiment 2

[0041] A preparation method of a silicone rubber-based DC cable accessory material is as follows:

[0042] One, copper acetate monohydrate in molar ratio: calcium nitrate tetrahydrate: n-tetrabutyl titanate=1:3:4, and according to the volume ratio of n-butyl titanate: n-tetrabutyl titanate: dehydrated alcohol: Acetic acid=3:50:1, measure 20ml dehydrated alcohol, 0.4ml acetic acid, 1.2ml n-tetrabutyl titanate and take 0.517g monohydrate copper acetate and 0.218g calcium nitrate tetrahydrate respectively, dehydrated alcohol, Acetic acid was poured into the beaker in turn and stirred evenly, copper acetate monohydrate was added to the above mixed solution and dissolved completely, and then calcium nitrate tetrahydrate was added to the mixed solution to completely dissolve calcium nitrate tetrahydrate to obtain a clear mixed solution; Add n-butyl titanate to the clarified mixed solution, and continue stirring at a stirring speed of 200r / min for 40min to disperse n-butyl titanate e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com