Method for rapidly separating endohedral metallofullerenes

A technology of metallofullerene and fullerene, which is applied in the direction of fullerene and nano-carbon, can solve the problem of inability to quickly and efficiently separate inner metallofullerene, and achieve the effect of simple operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

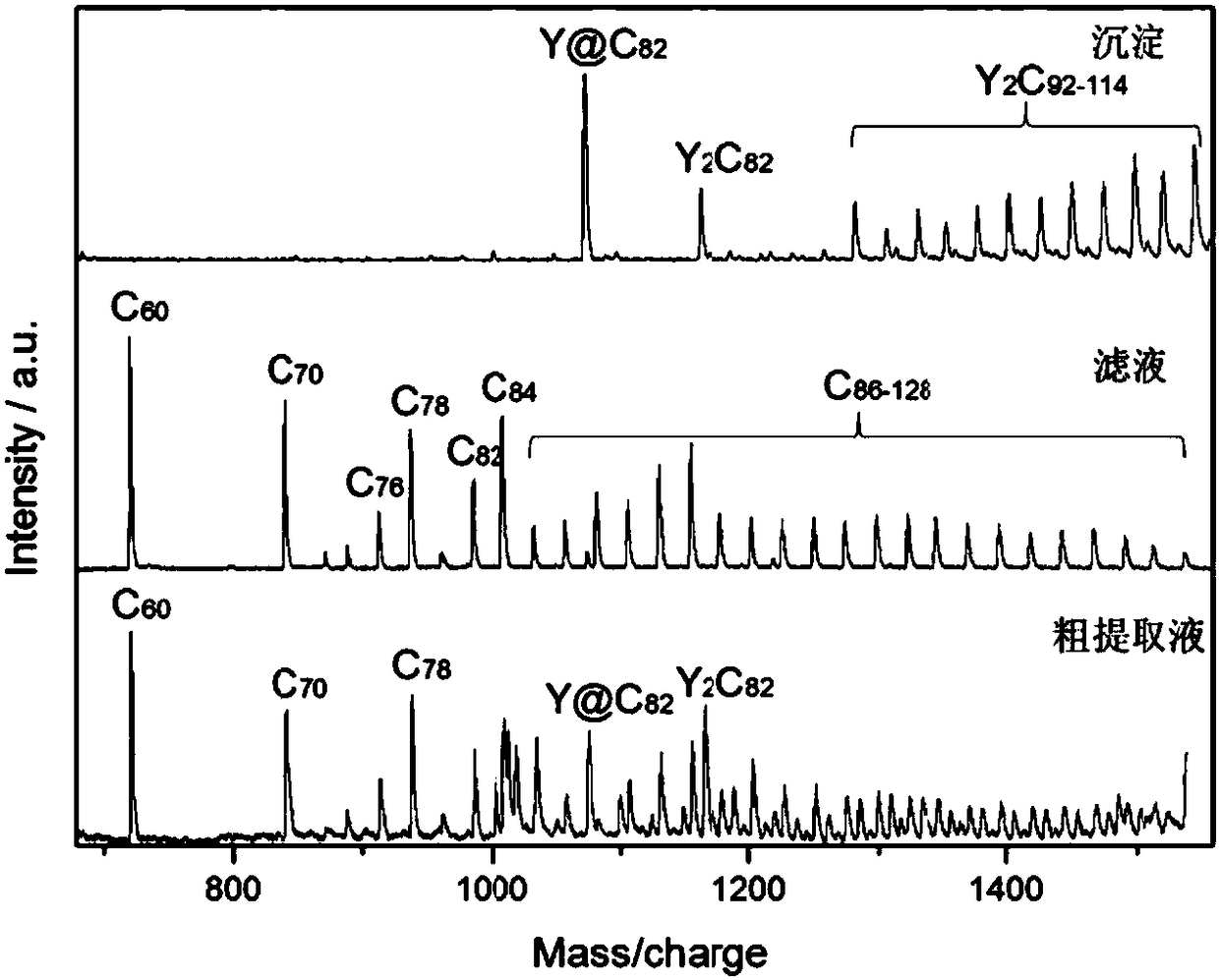

Embodiment 1

[0028] Completely dissolving a fullerene mixture containing metal yttrium fullerene in carbon disulfide to obtain a solution to be separated, mixing tin tetrachloride and the solution to be separated at a volume ratio of 1:500, and vigorously stirring for 24 hours to obtain a precipitate; The precipitate is washed with water, and then naturally dried to obtain the metal-encapsulated yttrium fullerene.

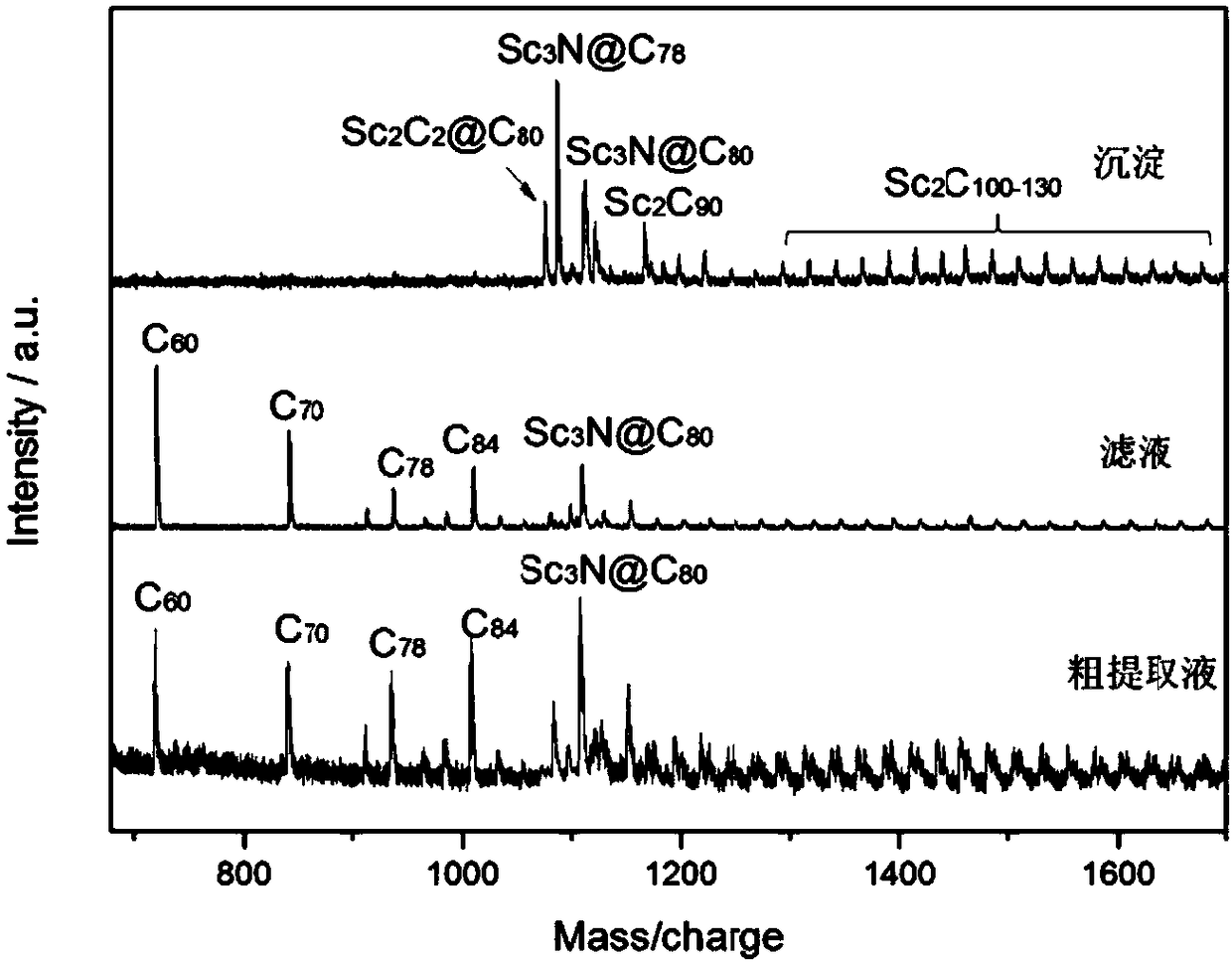

Embodiment 2

[0030] Completely dissolving the fullerene mixture containing scandium metal fullerene in carbon disulfide to obtain a solution to be separated, mixing tin tetrachloride and the solution to be separated at a volume ratio of 1:250, and vigorously stirring for 24 hours to obtain a precipitate; The precipitation is washed with water, and then naturally dried to obtain the scandium metal-encapsulated fullerene.

Embodiment 3

[0032] Completely dissolving a fullerene mixture containing metal lanthanum fullerene in toluene to obtain a solution to be separated, mixing titanium tetrachloride and the solution to be separated at a volume ratio of 1:350, and vigorously stirring for 24 hours to obtain a precipitate; The precipitate is washed with water, and then naturally dried to obtain the metal-encapsulated lanthanum fullerene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com