Spatial rope net based on constant force tearing belt

A technology of tearing belts and rope nets, which is applied to space navigation equipment, space navigation aircraft, space navigation equipment, etc. Effective working distance increase, effect of increasing effective working time and effective working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

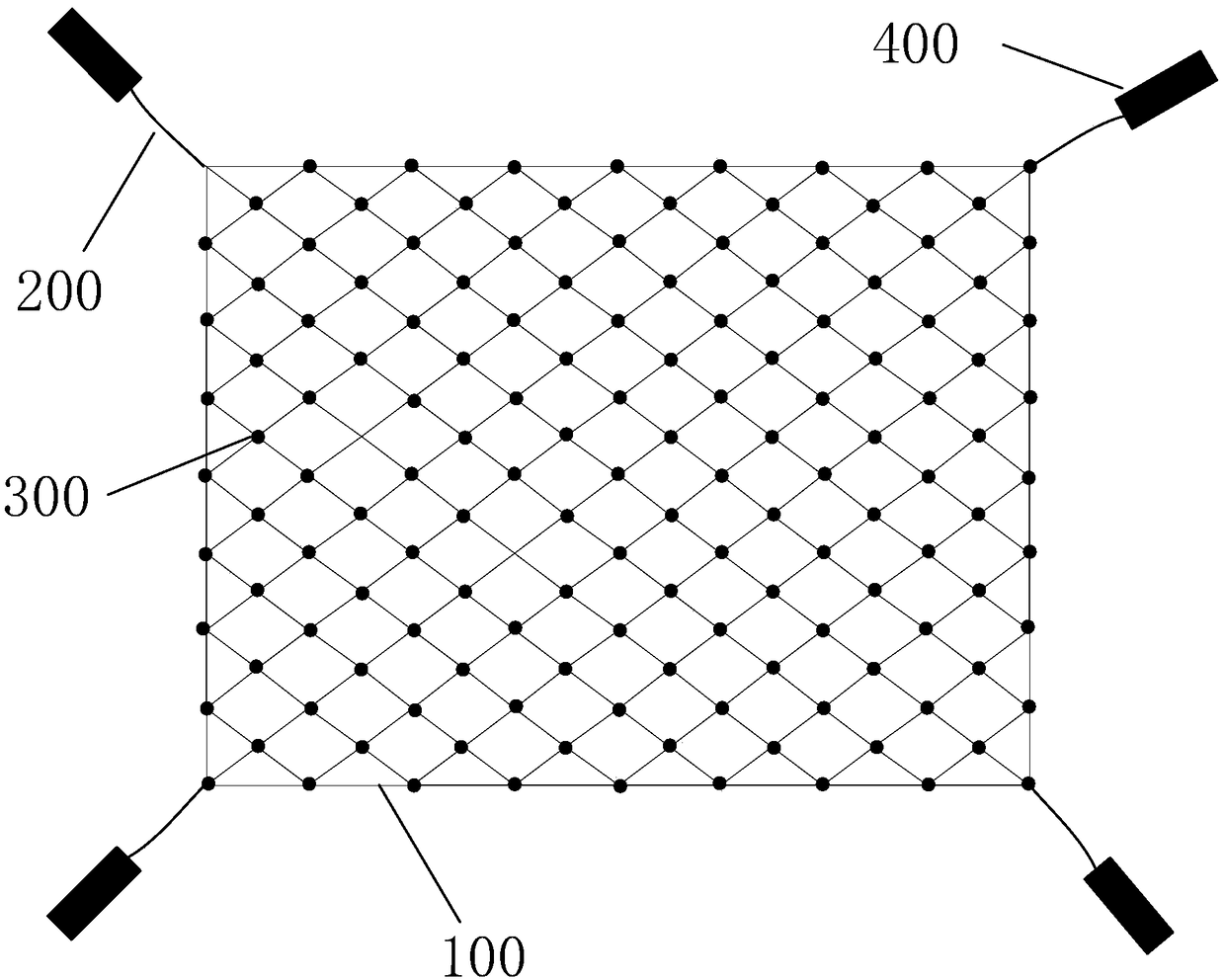

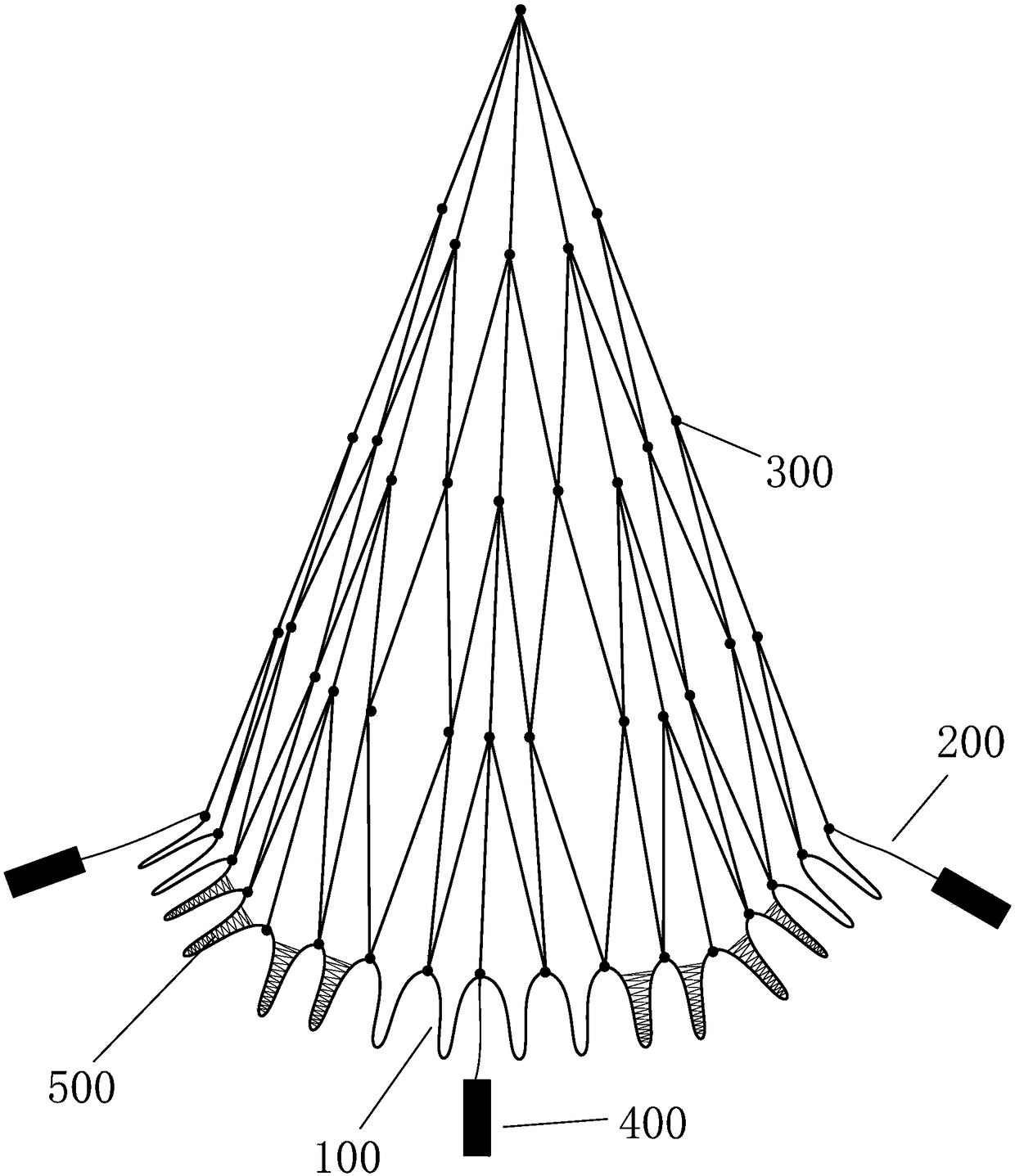

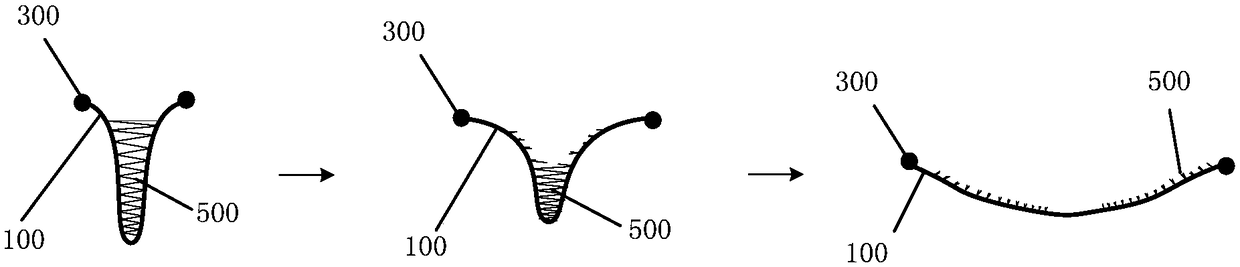

[0022] see figure 1 , the space rope net based on the constant force tearing belt 500 provided by the present invention includes: braided rope net, side line rope 100, traction rope 200, rope node 300, and the space rope for pulling the said based on constant force tearing belt 500 The quality block 400 that the net is deployed and moves forward and the constant force tearing belt 500 used to reduce the rebound during the deployment of the space rope net. The four corners of the sideline rope 100 are respectively provided with traction ropes 200 , and the free ends of the traction ropes 200 are connected with mass blocks 400 . During the launching proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com