A kind of shell and its preparation method and electronic product

A technology for electronic products and casings, which is applied to casings and their preparation methods and the field of electronic products, can solve the problems of increasing casing thickness, defect rate, and small bonding force, and achieves reducing production costs, improving product yields, and reducing screen sticking processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

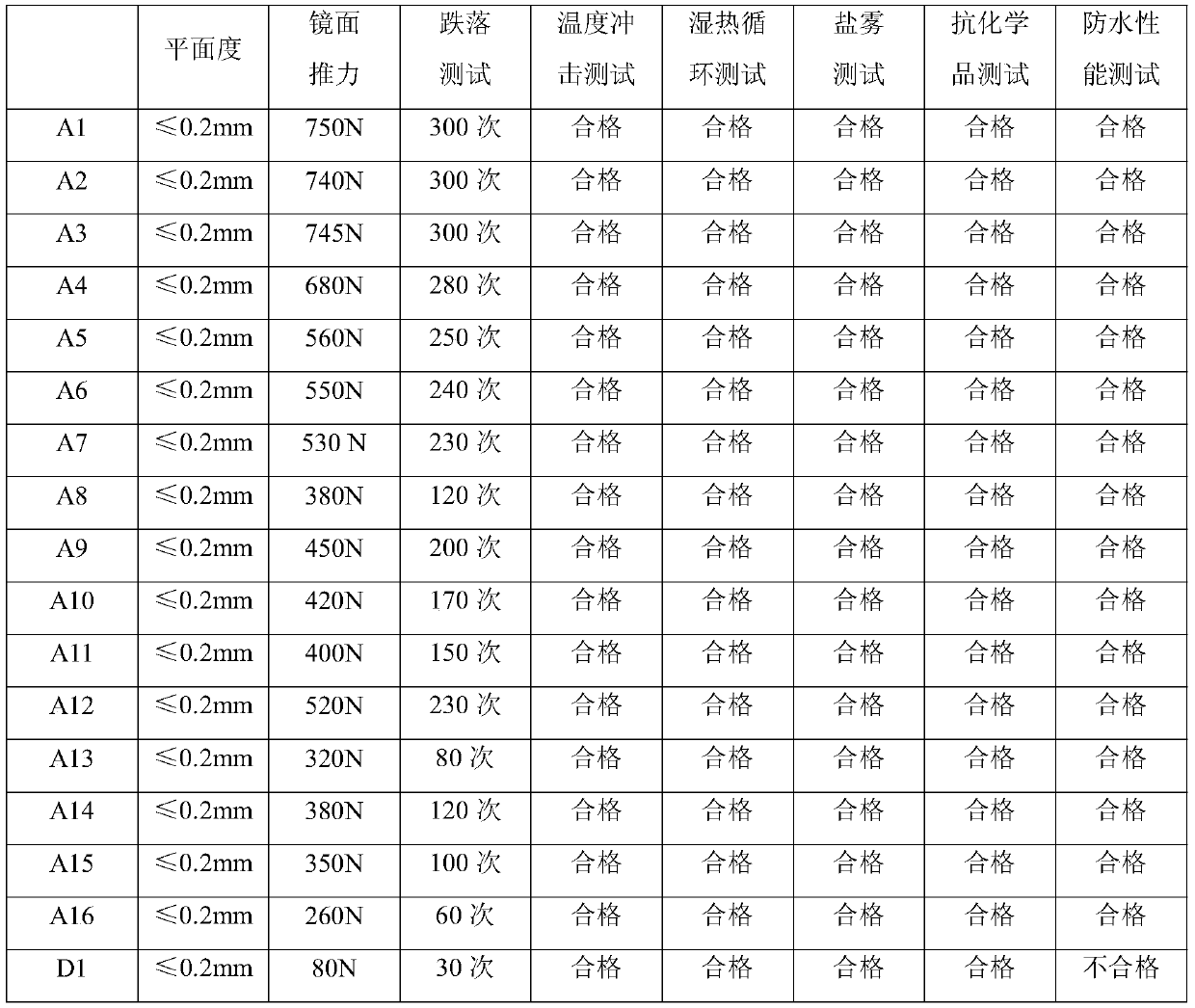

Examples

preparation example Construction

[0022] In a second aspect, the present invention provides a method for preparing a shell, the method comprising:

[0023] (1) coating activator on the edge of glass cover plate, drying;

[0024] (2) Combining the glass cover plate obtained in step (1) with the metal substrate frame by injection molding.

[0025] In the method of the present invention, preferably, the method further includes: in step (1), before coating the activator, coating ink at least on the edge of the glass cover and curing it. Among them, it can be determined which parts of the glass cover to apply ink to according to the application of the casing. The function of shielding the ITO circuit; if the shell is used as the shell of the back screen cover, coating ink on the inner surface (including the edge of the inner surface) of the glass cover mainly plays the role of displaying the color of the back screen cover shell.

[0026] In the method of the present invention, in step (1), in order to improve the...

Embodiment 1

[0069] (1) Roughen the edge of the OGS touch screen tempered glass, and use a 70T screen to print UV ink on the edge of the glass. The thickness of the UV ink is 10 μm, and then expose it for 3 minutes under a 900kW exposure machine; use 380 mesh The activator is screen-printed on the UV ink with a screen printing thickness of 10 μm, and then the glass is dried in a tunnel dryer at 90°C for 90 minutes; the activator is a polyurethane system, including polyurethane, acetone and ethylenediamine , based on the weight of the activator, the contents of polyurethane, acetone and ethylenediamine are respectively 88% by weight, 8% by weight and 4% by weight.

[0070] (2) The aluminum alloy is processed and shaped, polished, chemically polished, sand blasted, anodized, microporously treated, and film-coated in sequence to obtain an aluminum alloy substrate frame, and then the same activator as in step (1) is coated Distributed on the inner edge of the aluminum alloy substrate frame, th...

Embodiment 2

[0074] (1) Roughen the edge of the OGS touch screen tempered glass, use a 70T screen to print thermosetting ink on the edge of the glass, the thickness of the thermosetting ink is 15 μm, and then dry it in an oven at 80°C for 90 minutes; use 300 The purpose screen is to screen-print the activator on the heat-setting ink. The thickness of the screen-printed activator is 15 μm, and then put the glass in a tunnel dryer at 80°C to dry for 110 minutes; the activator is a polyurethane system, including polyurethane, ethyl acetate and ethylene glycol, based on the weight of the activator, the contents of polyurethane, ethyl acetate and ethylene glycol are respectively 85% by weight, 10% by weight and 5% by weight.

[0075] (2) The aluminum alloy is processed and shaped, polished, chemically polished, sand blasted, anodized, microporously treated, and film-coated in sequence to obtain an aluminum alloy substrate frame, and then the same activator as in step (1) is coated Distributed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com