Novel type dual-spring constant-force-control clamping device

A clamping device, double spring technology, applied in decorative arts, processing models, manufacturing tools, etc., can solve the problems of easy to be broken, inconvenient adjustment, easy to cause accidents, etc., to achieve constant clamping force, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

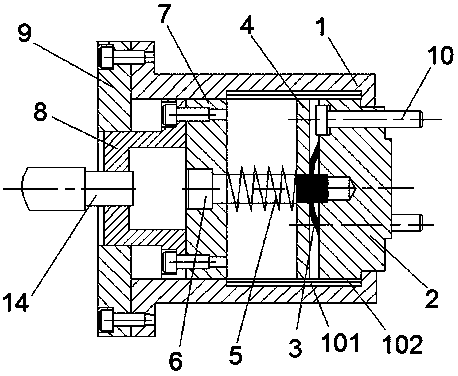

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

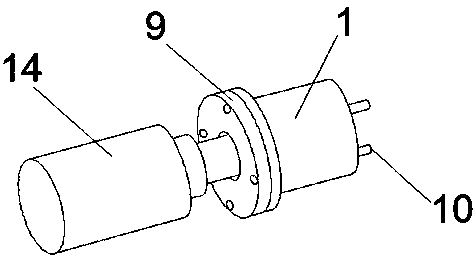

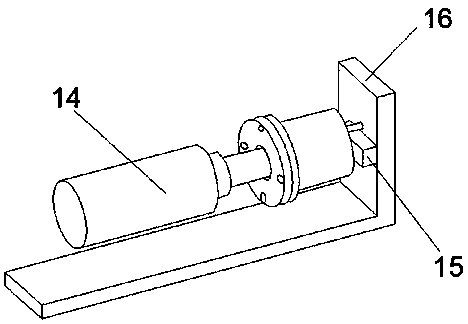

[0014] Such as Figure 1-Figure 4 As shown, a novel dual-spring type constant force control clamping device includes a hollow body 1, a clamping block 2, a force transmission assembly, a connecting block 8, a cover plate 9, a push rod 10 and a power device 14. The clamping block 2, the force transmission assembly, the connection block 8 and the cover plate 9 are installed in the body 1 from front to back, and the force transmission assembly includes a butterfly spring 3, a force transmission block 4, a cylindrical spring 5, a guide rod 6 and the guide block 7, the Belleville spring 3 is installed between the rear end of the clamping block 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com