Concrete production system

A production system and concrete technology, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc., can solve the problems of affecting construction quality, low durability, slow construction progress, etc., achieve fast calculation speed and improve the ratio Calculation and optimization speed, avoiding the effect of slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

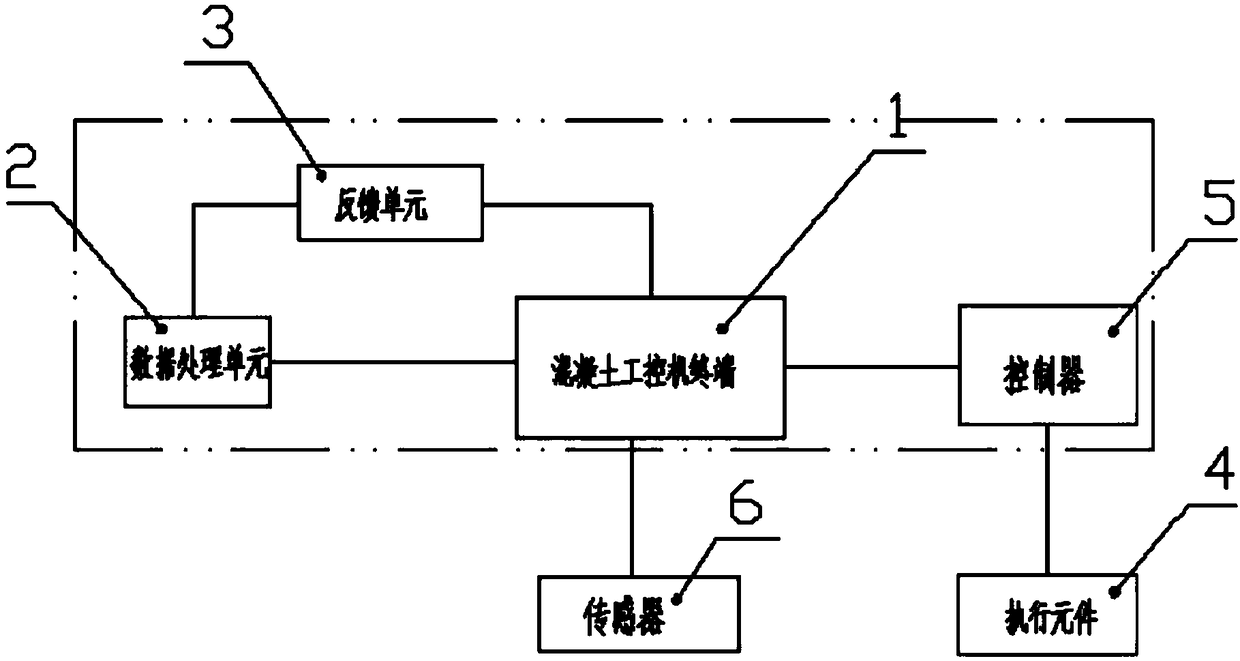

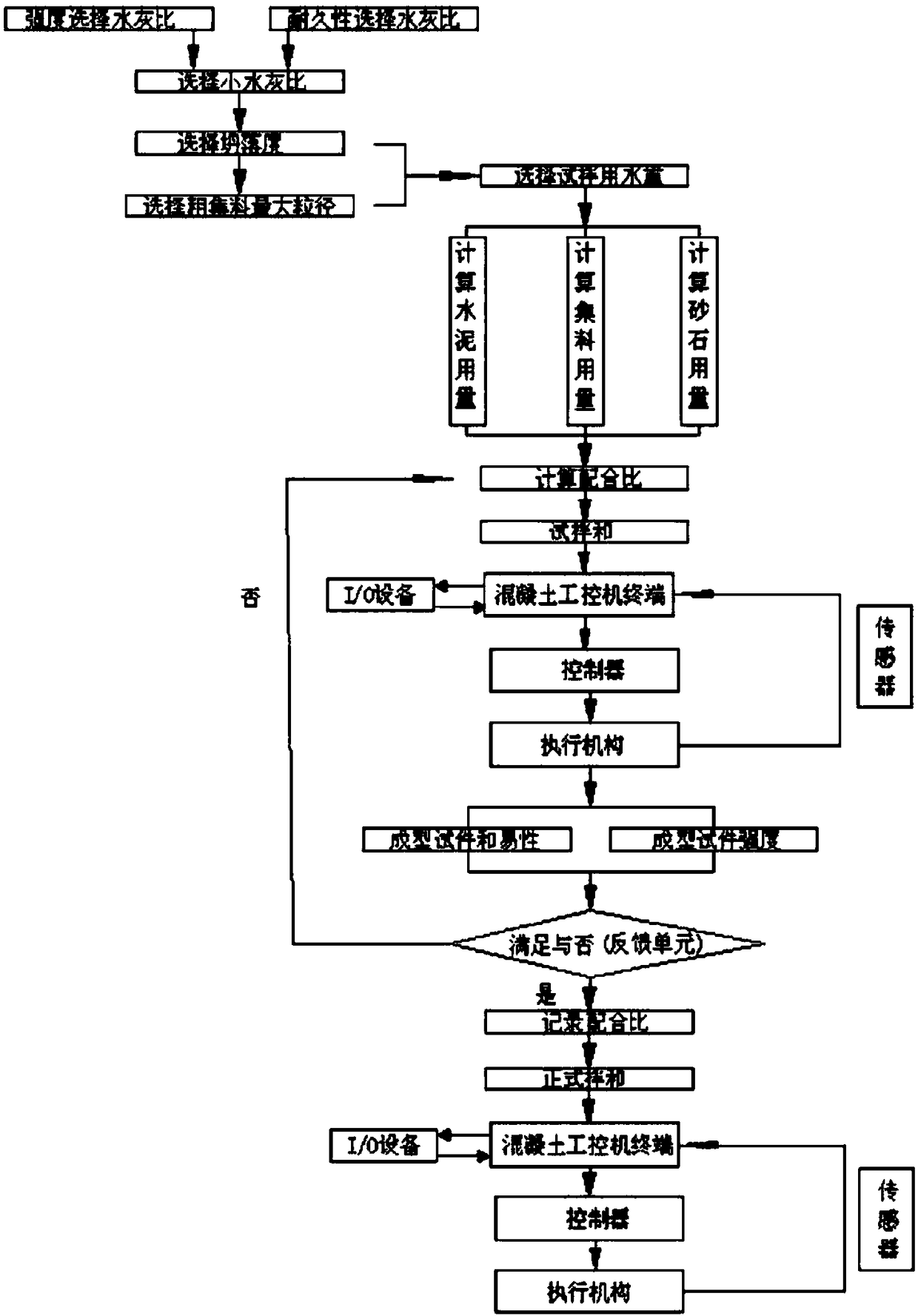

[0011] Such as figure 1 and figure 2 As shown, the concrete production system of the present invention includes a concrete industrial computer terminal 1 and a controller 5 electrically connected to the concrete industrial computer terminal 1, the controller 5 is electrically connected to an actuator 4, and the concrete industrial computer terminal 1 is electrically connected to a Data processing unit 2. Since the concrete industrial computer terminal 1 is electrically connected with a data processing unit 2, during work, the corresponding cement, aggregate, admixture, fly ash, Silica fume, water, choose a reasonable mix ratio, and adjust the relevant parameters to generate a reasonable concrete mix ratio, which can be quickly calculated by the data processing unit 2, which can greatly improve the construction progress. The data processing unit 2 can be realized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com