Painting device for valve handwheel

The technology of a painting device and hand wheel is applied to the device and coating of the surface coating liquid, which can solve the problems of backward processing method, low processing efficiency and increased workload, so as to speed up painting efficiency and improve processing. Quality, the effect of preventing the paint layer from being too thick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific implementations:

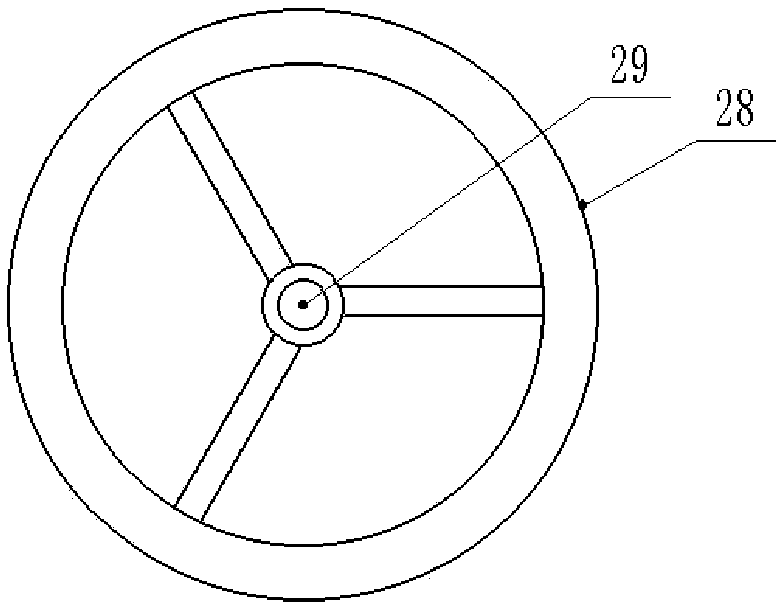

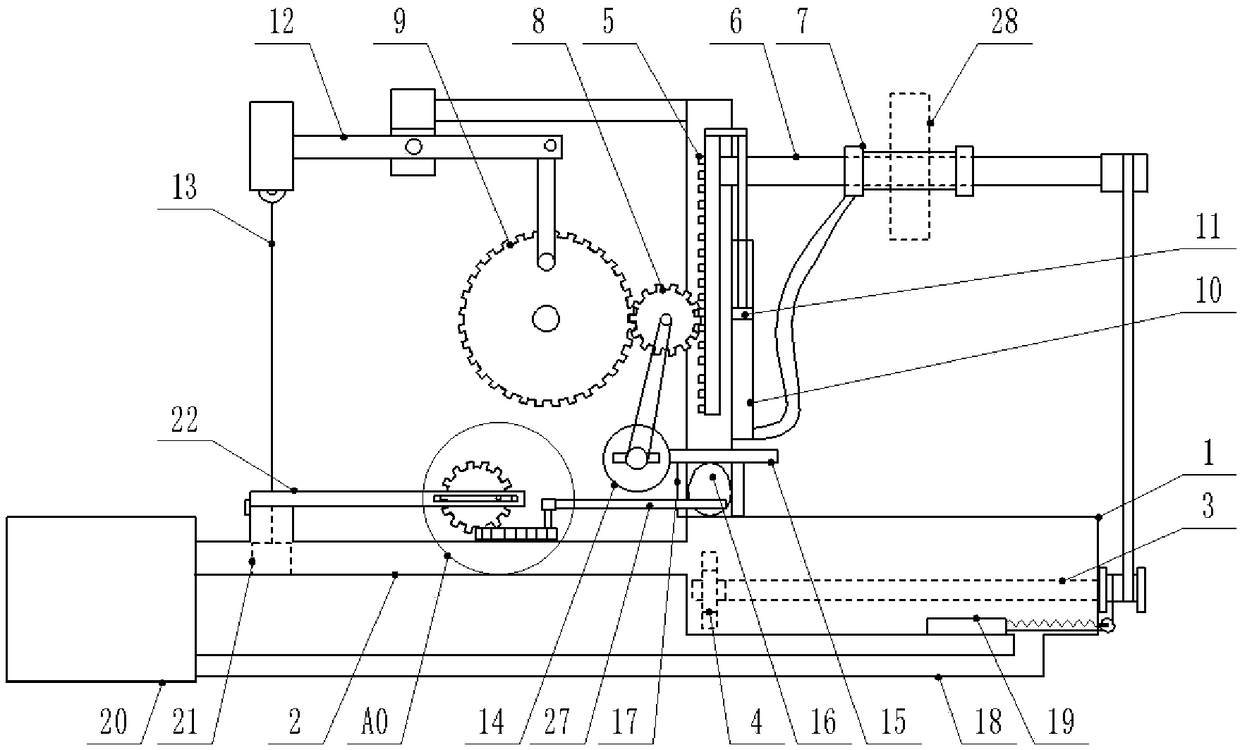

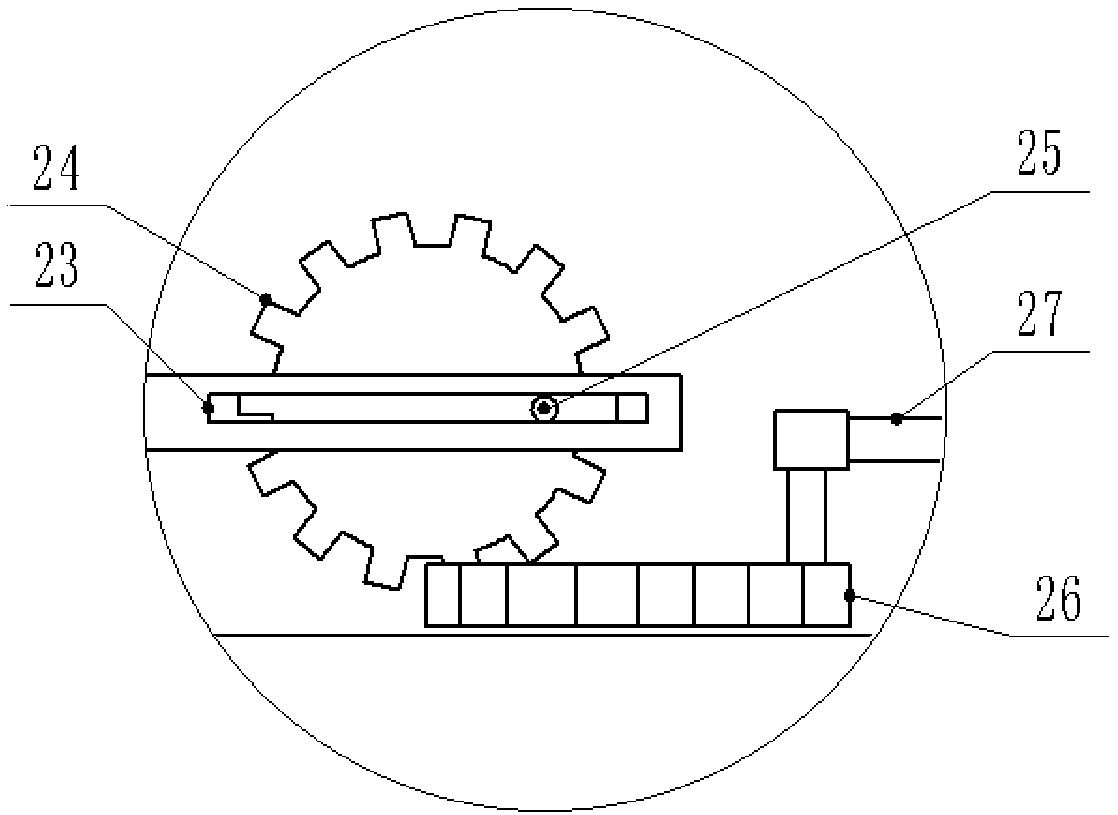

[0021] The reference signs in the drawings of the specification include: paint tank 1, paint inlet pipe 2, rotating shaft 3, turbine 4, rack 5, cross bar 6, elastic inflatable cylinder 7, pinion 8, large gear 9, vertical tube 10, Piston 11, lever 12, sling 13, fan 14, blowing pipe 15, air bag 16, vertical plate 17, paint discharge pipe 18, baffle 19, return box 20, gate 21, end cover 22, chute 23, first Gear 24, clamping column 25, second gear 26, push rod 27, hand wheel 28, and perforation 29.

[0022] This example figure 2 As shown, a painting device for a valve handwheel includes a paint tank 1, a paint inlet pipe 2 is connected to the left end of the paint tank 1, a branch pipe is welded on the paint inlet pipe 2, and a gate 21 is slidably connected to the paint inlet pipe 2. The gate 21 is located at the connecting port of the branch pipe and the paint inlet pipe 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com