Ethylenediamine-modified peach kernel cationic adsorbent and preparation method thereof

A cationic and adsorbent technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of poor adsorption performance of natural peach pits, and achieve low price, large market utilization space, and improved The effect of mild sexual conditioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

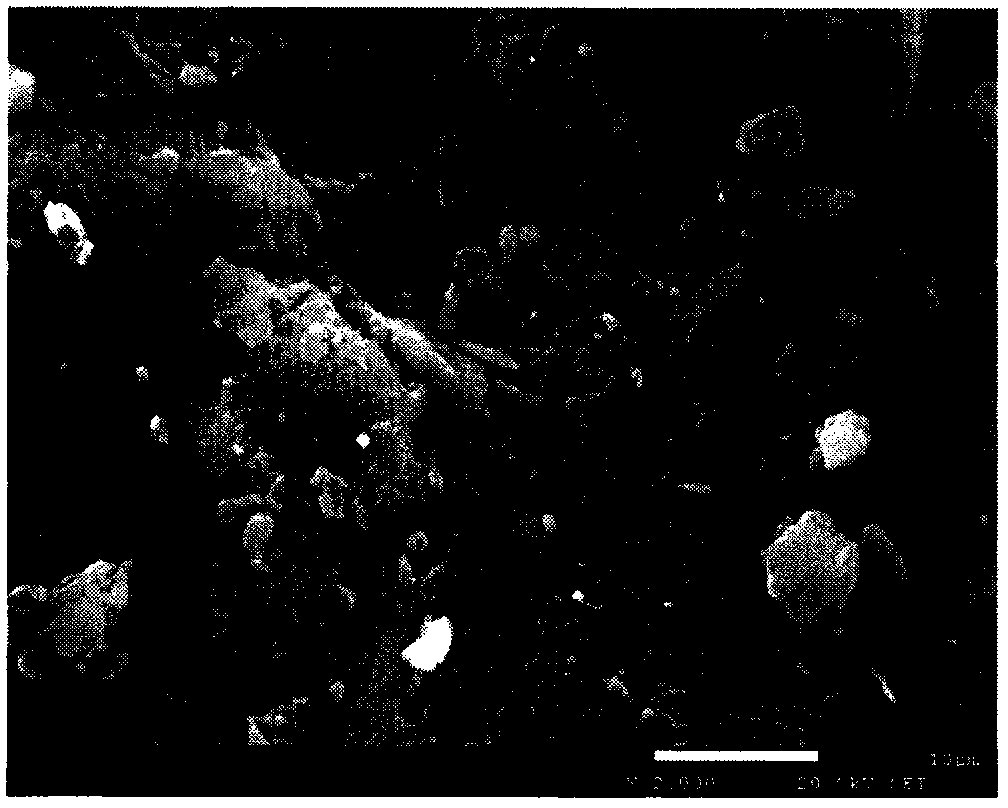

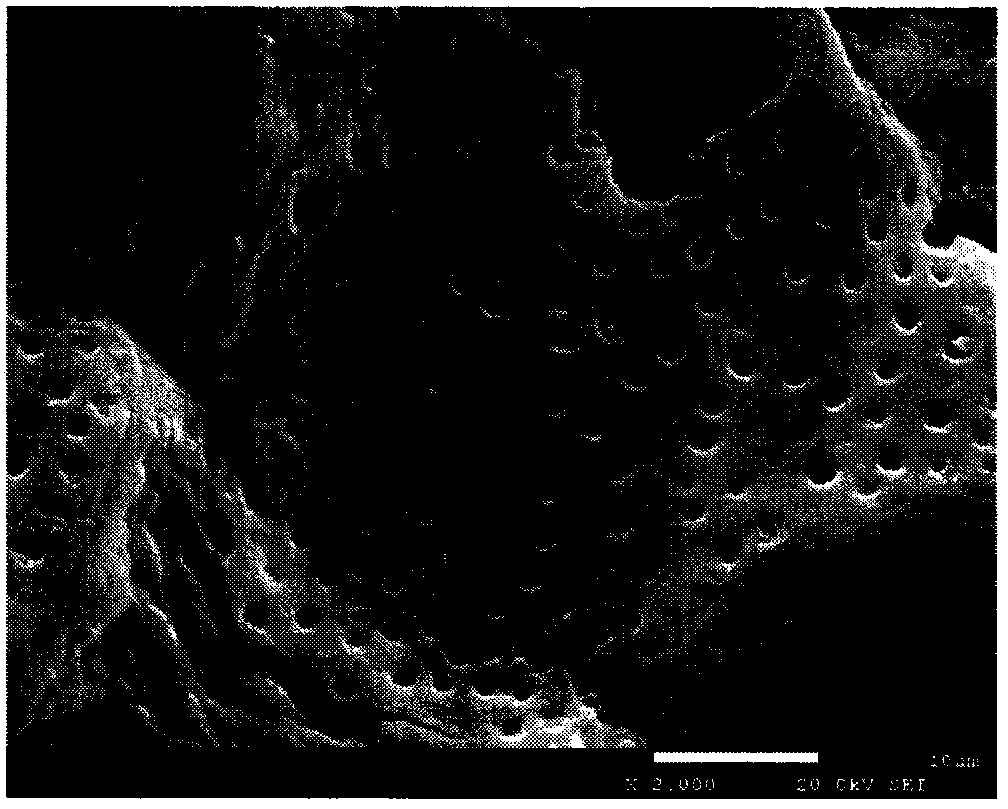

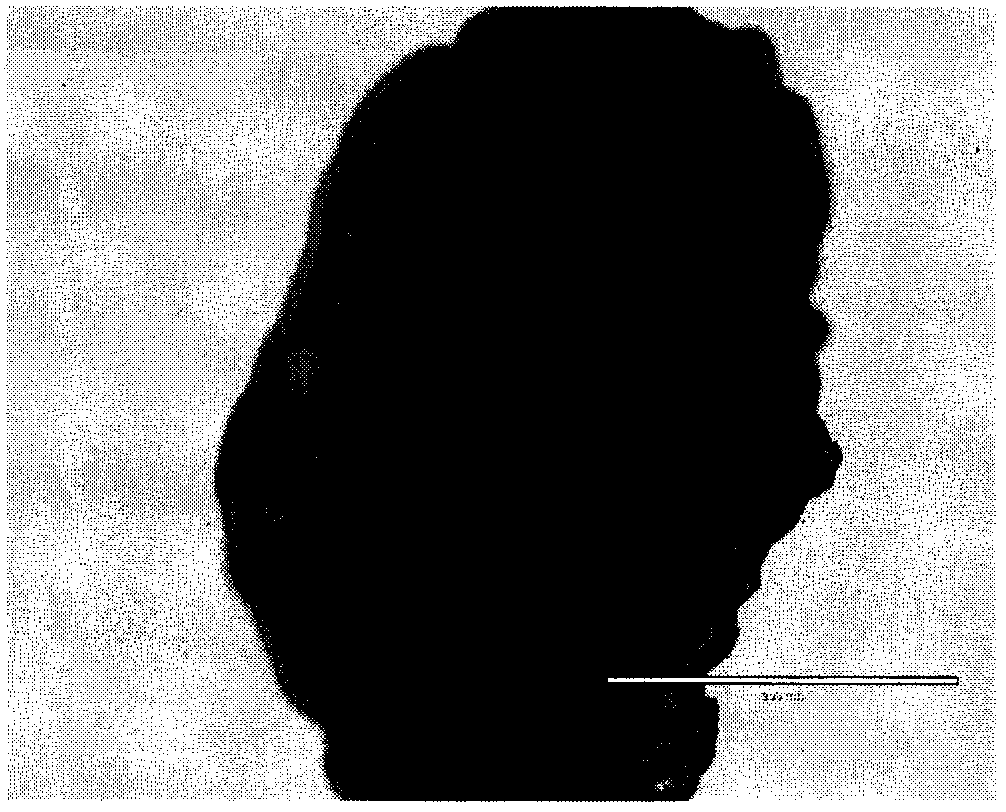

Image

Examples

example 1

[0028] This example investigates the adsorption effect of cationic adsorbent prepared by ethylenediamine modified peach pit on methyl orange wastewater, and investigates the adsorption effect of unmodified peach pit powder on methyl orange wastewater.

[0029] At room temperature, take 50 mL of a methyl orange solution with a concentration of 50 mg / L prepared in the laboratory. Weigh 0.2 g of the modified adsorbent in the solution, shake and adsorb at 150 rpm for 4 h, and measure its absorbance at a wavelength of 490 nm. The results showed that after 4 hours of adsorption, the absorbance of the solution decreased from 2.405 to 0.206, the removal rate was 91.43%, and the adsorption capacity was 11.43mg / g.

[0030] Under the same conditions, the absorbance of the unmodified peach stone powder group decreased from 2.405 to 2.299, the removal rate was only 4.407%, and the adsorption capacity was 0.55 mg / g. Compared with the unmodified peach kernel powder, the removal rate of meth...

example 2

[0032] This example investigates the adsorption effect of cationic adsorbent prepared by ethylenediamine modified peach pit on Chrome Black T wastewater, and investigates the adsorption effect of unmodified peach pit powder on Chrome Black T wastewater.

[0033] At room temperature, take 50 mL of chrome black T solution with a concentration of 50 mg / L prepared in the laboratory. Weigh 0.2g of the modified adsorbent and unmodified peach core in the solution, shake and absorb at 150rmp for 4h, then measure the absorbance at a wavelength of 490nm. The results showed that after 4 hours of adsorption, the absorbance of the solution decreased from 0.168 to 0.020, the removal rate was 88.09%, and the adsorption capacity was 11.01mg / g.

[0034] Under the same conditions, the absorbance of the unmodified peach pit powder group decreased from 0.168 to 0.100, the removal rate was only 40.47%, and the adsorption capacity was 5.06 mg / g. Compared with the unmodified peach stone, the peach st...

example 3

[0036] This example investigates the adsorption effect of cationic adsorbent prepared by ethylenediamine modified peach pit on Congo red wastewater, and investigates the adsorption effect of unmodified peach pit powder on Congo red wastewater.

[0037] At room temperature, take 50 mL of the Congo red solution prepared in the laboratory with a concentration of 50 mg / L. Weigh 0.2g of the modified adsorbent and unmodified peach core in the solution, shake and absorb at 150rmp for 4h, then measure the absorbance at a wavelength of 490nm. The results showed that after 4 hours of adsorption, the absorbance of the solution decreased from 0.568 to 0.036, the removal rate was 93.66%, and the adsorption capacity was 11.71mg / g.

[0038] Under the same conditions, the absorbance of the unmodified peach stone powder group decreased from 0.568 to 0.558, the removal rate was only 1.76%, and the adsorption capacity was 0.22 mg / g. Compared with the unmodified peach stone, the removal rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com