Liquid ammonia stirring vessel temperature regulating device

A technology of temperature control device and dissolution kettle, which is applied in the field of reactors, can solve problems such as temperature rise, liquid ammonia escape, and sticky materials, and achieve the effect of accelerating the dropping speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

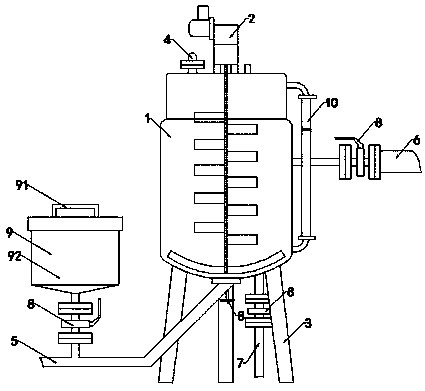

[0009] Depend on figure 1 It is known that it is a structural schematic diagram of the present invention, a temperature control device for a liquid ammonia dissolution kettle, including a UV dissolution kettle 1; the UV dissolution kettle 1 is provided with a stirring device 2 for standing support through support feet 3, and the UV dissolution kettle 1 is provided with feed pipe 4, discharge pipe 5, heat transfer oil inlet pipe 6 and heat transfer oil outlet pipe 7, and feed pipe 4, discharge pipe 5, heat transfer oil inlet pipe 6 and heat transfer oil outlet pipe 7 are all provided with There is a control valve 8; the extension of the discharge pipe 5 is provided with an additive feeding device 9, and the connection between the additive feeding device 9 and the discharge pipe 5 is provided with a control valve 8. One side of the kettle body of the UV dissolution kettle 1 is provided with a solution height measuring device 10, and the solution height measuring device 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com