Gas purification device and method

A gas purification device and gas technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve problems such as hidden safety hazards and poor dust removal effect, and achieve the effects of reducing impact, simple structure, and increasing dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

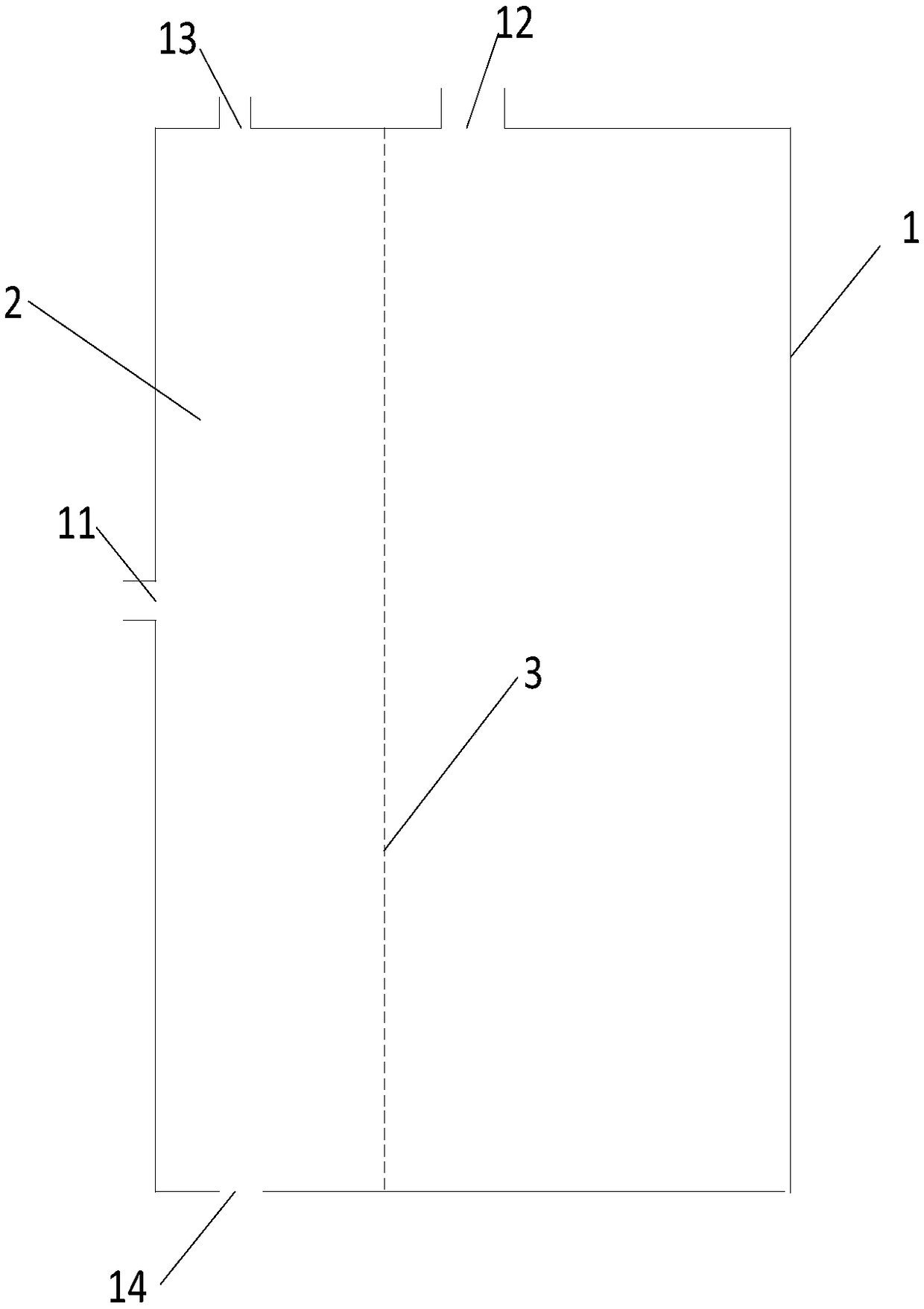

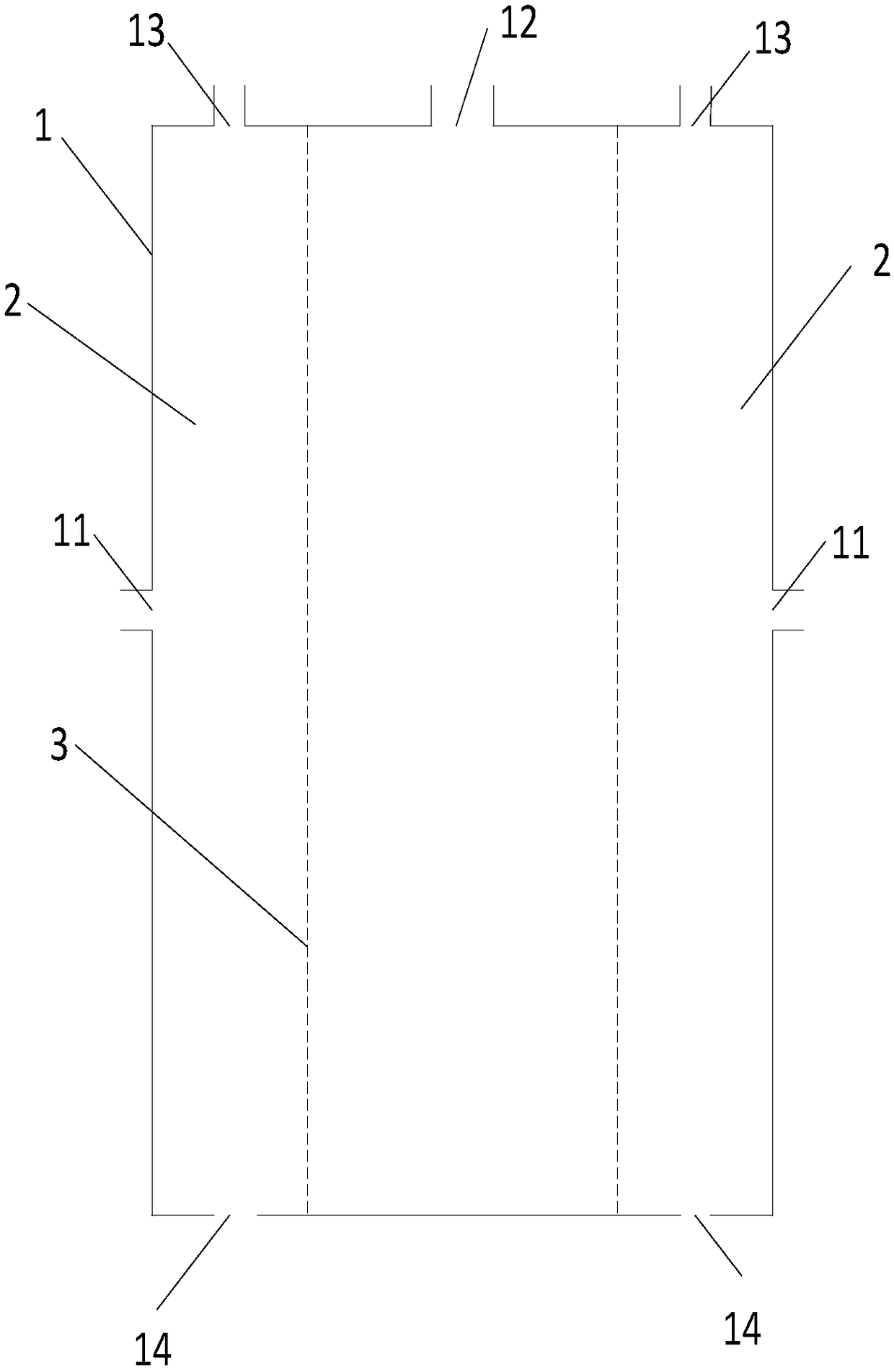

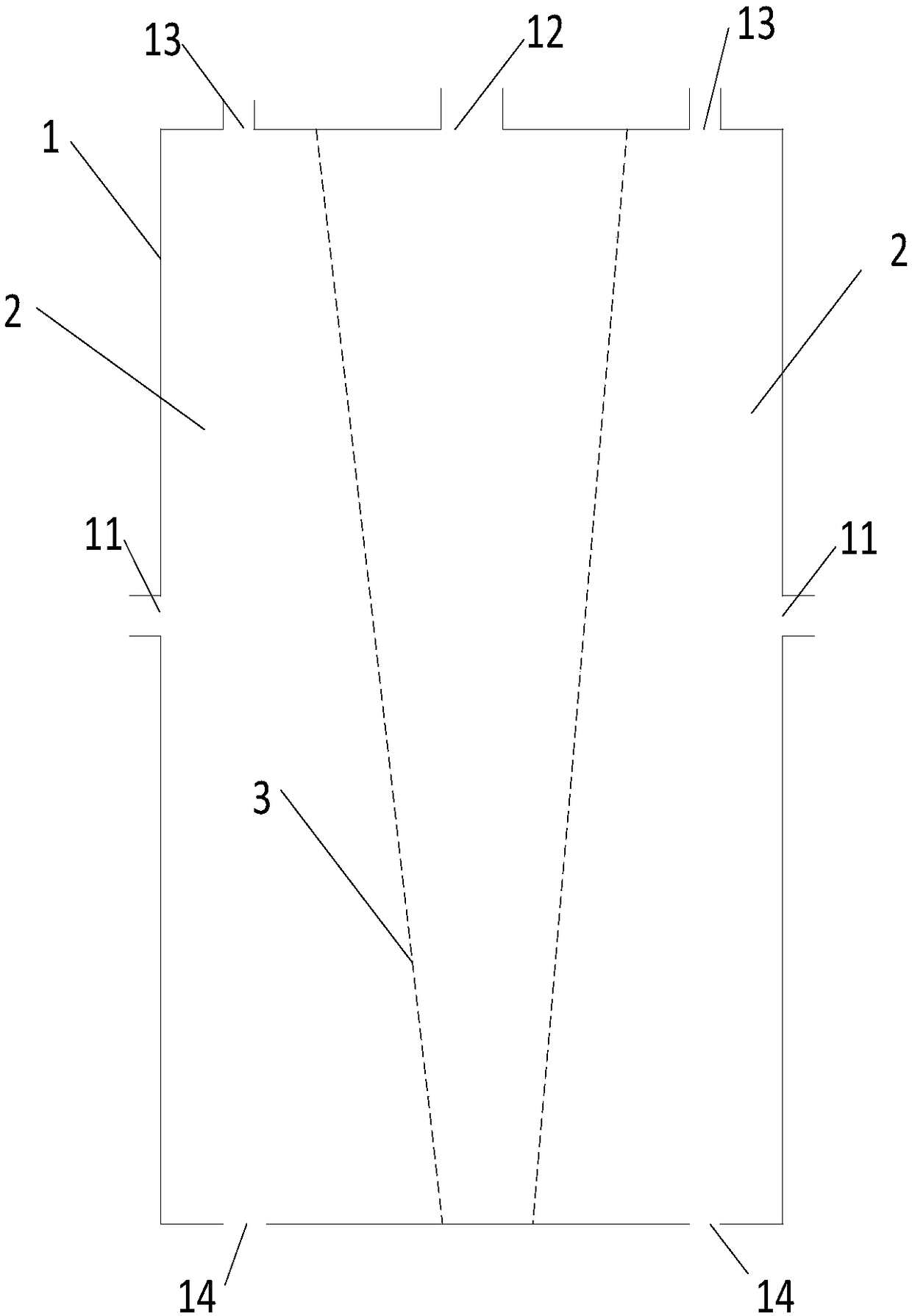

[0043] Such as figure 1 As shown, a gas purification device includes a housing 1, the housing 1 is provided with an air inlet 11 and an air outlet 12, and the top and bottom of the housing 1 are respectively provided with a filling inlet 13 and a filling outlet 14 ; The housing 1 is provided with at least one primary packing channel 2 that allows the packing to flow, and the primary packing channel 2 is connected to the packing inlet 13, the packing outlet 14, the air inlet 11 and the The gas outlet 12 is connected; the filler in the primary filler channel 2 moves from the filler inlet 13 to the filler outlet 14 . The first-stage packing channel 3 may be provided with several air outlets, and the air outlets communicate with the air outlet 12 ; The hole diameter of the air outlet is set to be smaller than the particle size of the filler to avoid leakage of the filler through the air outlet.

[0044] The dust-laden dust-laden gas enters the first-stage packing channel from th...

Embodiment 2

[0059] The temperature of the dusty gas treated in this example is 500°C, and the dust concentration is 40g / m 3 ; The filler is magnesium aluminum spinel, and its temperature is 300°C;

[0060] This embodiment provides a method for gas purification, including:

[0061] Flow the dusty gas at 10m / s 2 The air velocity through the flow velocity is 2m / s 2 Filler, wherein the mass volume ratio (g / mL) of the amount of filler to high-temperature gas is 10:1, and the flow direction of the dusty gas is perpendicular to the flow direction of the filler.

[0062] The dust concentration in the dust-containing gas after dust removal is detected to be 6g / m 3 .

Embodiment 3

[0064] The temperature of the dusty gas treated in this example is 300°C, and the dust concentration is 40g / m 3 The filler used in the first filler channel is porous ceramics, the filler used in the second filler channel is aluminum oxide, and the filler in the third filler channel is cordierite; in the first, second and third filler channels The temperature of the filler is 400°C; the gas purification device in which two partitions are arranged in parallel in the second embodiment in Example 1 is adopted;

[0065] include:

[0066] Flow the dusty gas at 10m / s 2 The air velocity enters the shell from the air inlet and is discharged from the air outlet; the flow velocity of the packing in the first, second and third packing channels is 1m / s 2 The filler, wherein the mass volume ratio (g / mL) of the filler in the first, second and third channels to the high-temperature gas is 3:1.

[0067] The dust concentration at the gas outlet is 5g / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com