Weeding composition

A herbicidal composition and a technology for cyhalofop-butyl are applied in the field of agricultural chemistry, can solve the problems of difficult to produce obvious effects, complex weeds in farmland, difficult green pesticides, etc., and achieve excellent control effect, weed killing Broad spectrum, delaying weed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

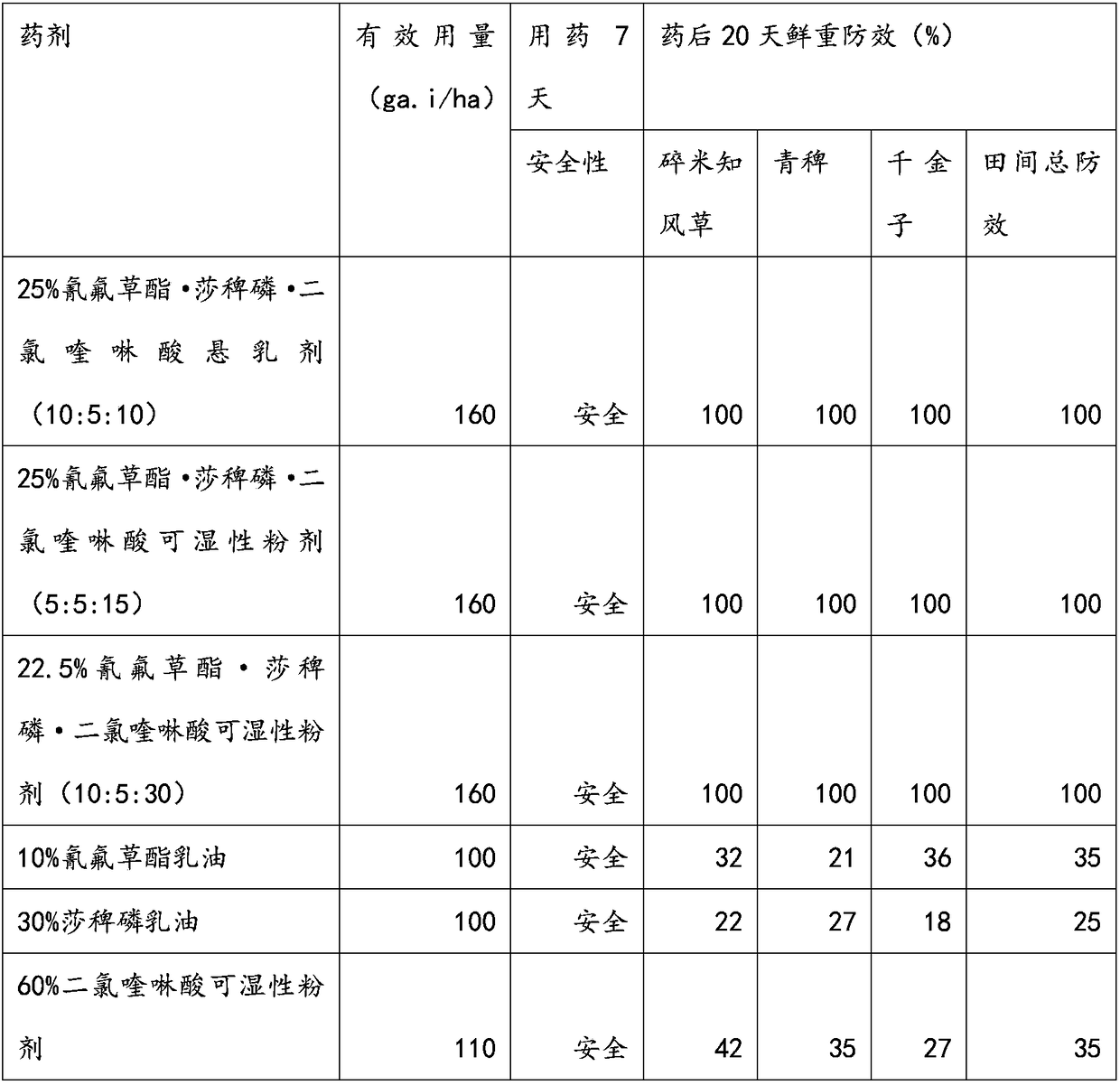

Embodiment 1

[0022] In order to control weeds in paddy fields, the inventors used the active ingredients of cyhalofop-methyl, saponin and quinclorac to conduct synergistic research on the mutual compounding. The specific method is: the test targets are Eragrostis japonica (Thunb.). The original drug is prepared into the required test agent, and the test method refers to the "People's Republic of China Agricultural Industry Standard NY / T1155.7-2006 Indoor Bioassay Test Guidelines for Pesticides and Herbicides Part 7: Determination of Combined Effects of Mixing". Firstly, the single agent and each mixed agent are set to 5-7 different concentrations. Set water control, repeated 4 times. Adopt post-emergence stem-leaf spraying method, prepare the weeds for testing in advance, wait for the weeds 3 leaf 1 heart stage for standby, use the spray tower (Nanjing Institute of Agricultural Mechanization, Ministry of Agriculture, 3WPSH-500D, spraying pressure 3.0 kg / cm 3 ) evenly sprayed on the weed...

Embodiment 1

[0030] Formulation example 1: 25% cyhalofop-methyl, saponin, quinclorac suspoemulsion (10:5:10)

[0031] Methazone 10%, 5% sapylphos, 10% quinclorac, 15% C9-10 heavy aromatic solvent oil, 10% N,N-dimethyl caprylamide, castor oil polyoxyethylene ether 3.6 %, 3% of hydroxyl polyoxyethylene block copolymer, mixed to obtain an oil phase for use. 10% fenpyramid, 5% saponin, 10% quinclorac, 1% wetting agent polyoxyethylene polyoxypropylene block polyether, 3.5% dispersing agent phosphatidic ester, thickener xanthan Glue 0.5%, preservative Cathone 0.2%, antifreeze ethylene glycol 5%, defoamer silicone 0.2%, water to make up to 100%. Mix fenpyramid, saponin, quinclorac, wetting agent, dispersant, preservative, antifreeze, and water with a shearing machine at high speed, and then sand them through a sand mill until the material is granulated. Diameter D90<3um, obtain mother liquor, add oily phase, thickener successively in mother liquor high-speed shearing process and continue sheari...

Embodiment 2

[0032] Formulation example 2: 25% cyhalofop-methyl, saponin, quinclorac wettable powder (5:5:15)

[0033]5% cyhalofop, 5% saponin, 15% quinclorac, 7% calcium dodecylbenzene sulfonate, 6% alkyl naphthalene sulfonate, 5% lignosulfonate, hydroxyl poly Oxyethylene block copolymer 2.4%, solvent naphtha S150 10%, white carbon black 7%, filler kaolin to 100%. After completely dissolving cyhalofop-ethyl and saponin in solvent naphtha S150, mix the hydroxyl polyoxyethylene block copolymer evenly, and completely adsorb it with white carbon black for 24 hours. After fully mixing all the components, carry out jet milling to obtain 25% cyanide Fluoxate, saponin, quinclorac wettable powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com