Refining method for medicinal sucrose

A refining method and technology of medicinal sucrose, applied in the field of medicine and chemical industry, can solve problems such as high production cost, difficult industrialization, and complexity, and achieve the effect of improving quality, low price, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

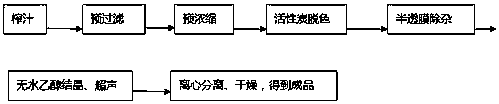

Method used

Image

Examples

Embodiment 1

[0031] Squeeze sugarcane through a juicer to obtain sugarcane juice, pre-filter through a filter to remove larger bagasse, 70 oC Perform pre-concentration treatment under certain conditions, then add activated carbon, heat and boil for 20 minutes, filter again, and then separate the filtered sucrose solution with a semi-permeable membrane to obtain a sucrose solution. Add the sucrose solution to absolute ethanol, and at the same time conduct ultrasound and crystallization on the solution. The volume ratio of the sucrose solution to absolute ethanol is 1:0.5, the ultrasonic power is 55W, and the crystal solution is centrifuged to obtain sucrose crystals, which are obtained after drying. Cane sugar products.

[0032] The final product has a pigment removal rate of 99.9%, a salt removal rate of 97.1%, a sucrose content of 99.9%, and a conductivity ash content of less than 0.01%, which meets national standards. The sucrose crystal particle size is 97nm, and the sucrose recovery r...

Embodiment 2

[0034] Squeeze sugarcane through a juicer to obtain sugarcane juice, pre-filter through a filter to remove larger bagasse, 80 oC Perform pre-concentration treatment under certain conditions, then add activated carbon, heat and boil for 25 minutes, filter again, and then separate the filtered sucrose solution with a semi-permeable membrane to obtain a sucrose solution. Add the sucrose solution to absolute ethanol, and at the same time conduct ultrasound and crystallization on the solution. The volume ratio of the sucrose solution to absolute ethanol is 1:10, the ultrasonic power is 400W, and the crystal solution is centrifuged to obtain sucrose crystals, which are obtained after drying. Cane sugar products.

[0035] The final product has a pigment removal rate of 99.9%, a salt removal rate of 98.8%, a sucrose content of 99.9%, and a conductivity ash content of less than 0.01%, which meets national standards. The sucrose crystal particle size is 35nm, and the sucrose recovery r...

Embodiment 3

[0037] Squeeze sugarcane through a juicer to obtain sugarcane juice, pre-filter through a filter to remove larger bagasse, 95 oC Perform pre-concentration treatment under certain conditions, then add activated carbon, heat and boil for 20 minutes, filter again, and then separate the filtered sucrose solution with a semi-permeable membrane to obtain a sucrose solution. Add the sucrose solution to absolute ethanol, and at the same time conduct ultrasound and crystallization on the solution. The volume ratio of the sucrose solution to absolute ethanol is 1:3, the ultrasonic power is 100W, and the crystal solution is centrifuged to obtain sucrose crystals, which are obtained after drying. Cane sugar products.

[0038] The final product has a pigment removal rate of 99.8%, a salt removal rate of 98.3%, a sucrose content of 99.9%, and a conductivity ash content of less than 0.01%, which meets national standards. The sucrose crystal particle size is 75nm, and the sucrose recovery ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com