A smoke exhaust pipe for connecting the exhaust port of a range hood

A technology of exhaust port and exhaust pipe, which is applied in the direction of oil fume removal, application, household stove, etc., can solve the problems of installation trouble and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

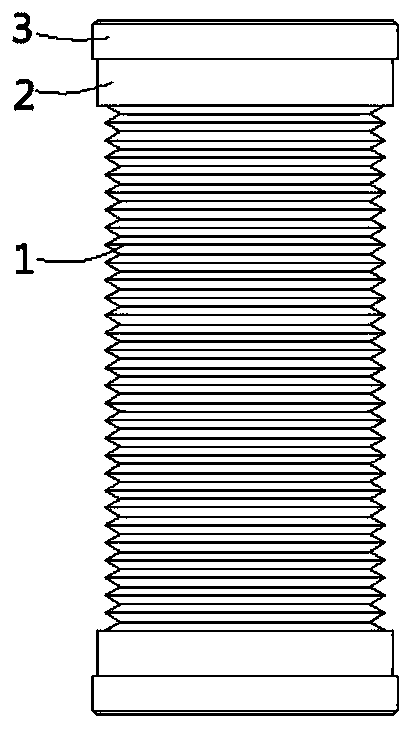

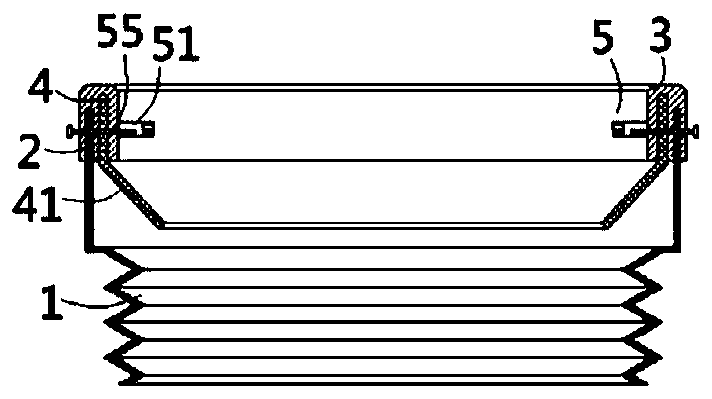

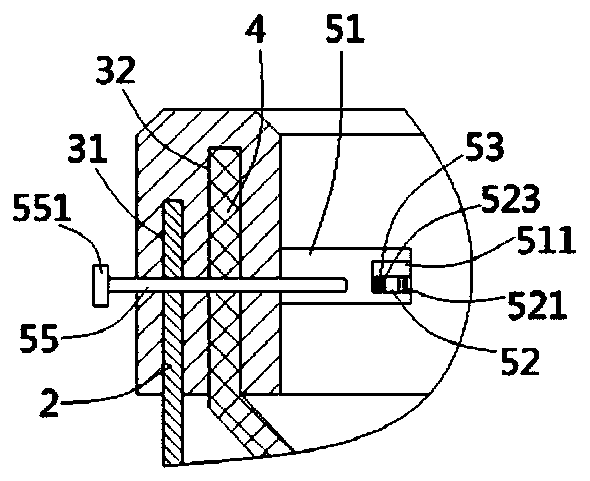

[0022] see Figure 1 to Figure 3 According to the present invention, a smoke exhaust pipe for connecting the exhaust port of range hoods includes a corrugated hose 1, the two ends of the corrugated hose 1 are formed with connecting sleeves 2, and the inner diameter of the corrugated hose 1 is smaller than the connecting sleeve. The inner diameter of the sleeve 2, the two ends of the corrugated hose 1 are provided with an annular sleeve 3, the lower end surface of the sleeve 3 is formed with an outer ring groove 31 and an inner ring groove 32, and the connecting sleeve 2 is inserted In the outer ring groove 31, an annular rubber sleeve 4 is inserted into the inner ring gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com