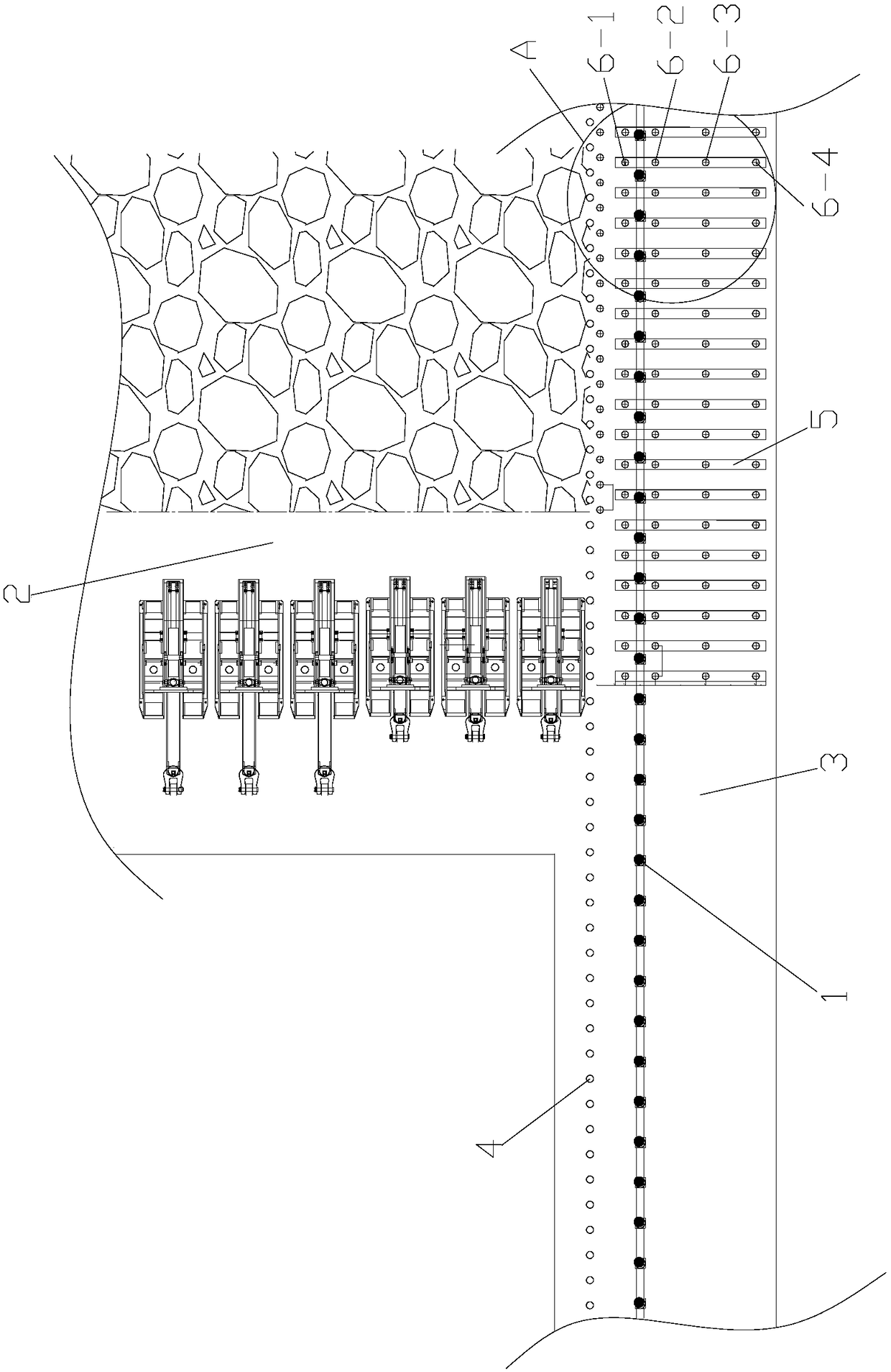

Gob-side entry retaining method for non-blasting roof-cutting and pressure releasing of soft-top coal seam

A roof-cutting, pressure-relief, non-blasting technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as unfavorable health of workers, threats to mine safety production, low compressive strength index, etc., and achieve saving of explosives consumption , Promote the application of high value and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0047] In this embodiment, the 21309 fully mechanized mining face is located in the middle of the Nanxiashan mining area and belongs to the 3# coal seam. The roadway is arranged along the coal seam strike. The strike length of the working face is 1171.6m on average, the inclined width is 205m, and the area is 240,0201.3 square meters. The auxiliary air intake roadway adopts cutting roof, pressure relief and roadway retention technology. The east is adjacent to the goaf of 21308 fully mechanized mining face, the south is bounded by a large fault with a drop of more than 10m, the west is adjacent to the designed 21310 fully mechanized mining face, and the north is bounded by the protection coal pillar of the south main channel of Hongqi Canal.

[0048] The 3# coal bed is semi-bright type. The coal bed is mainly bright coal, with thin strips of dark coal in the middle. The structure of the coal seam is simple. The lower part of the coal seam contains gangue locally, the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com