Profile oxidation production line and its production process

A production line and profile technology, applied in the direction of anodic oxidation, coating, surface reaction electrolytic coating, etc., can solve the problem of high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

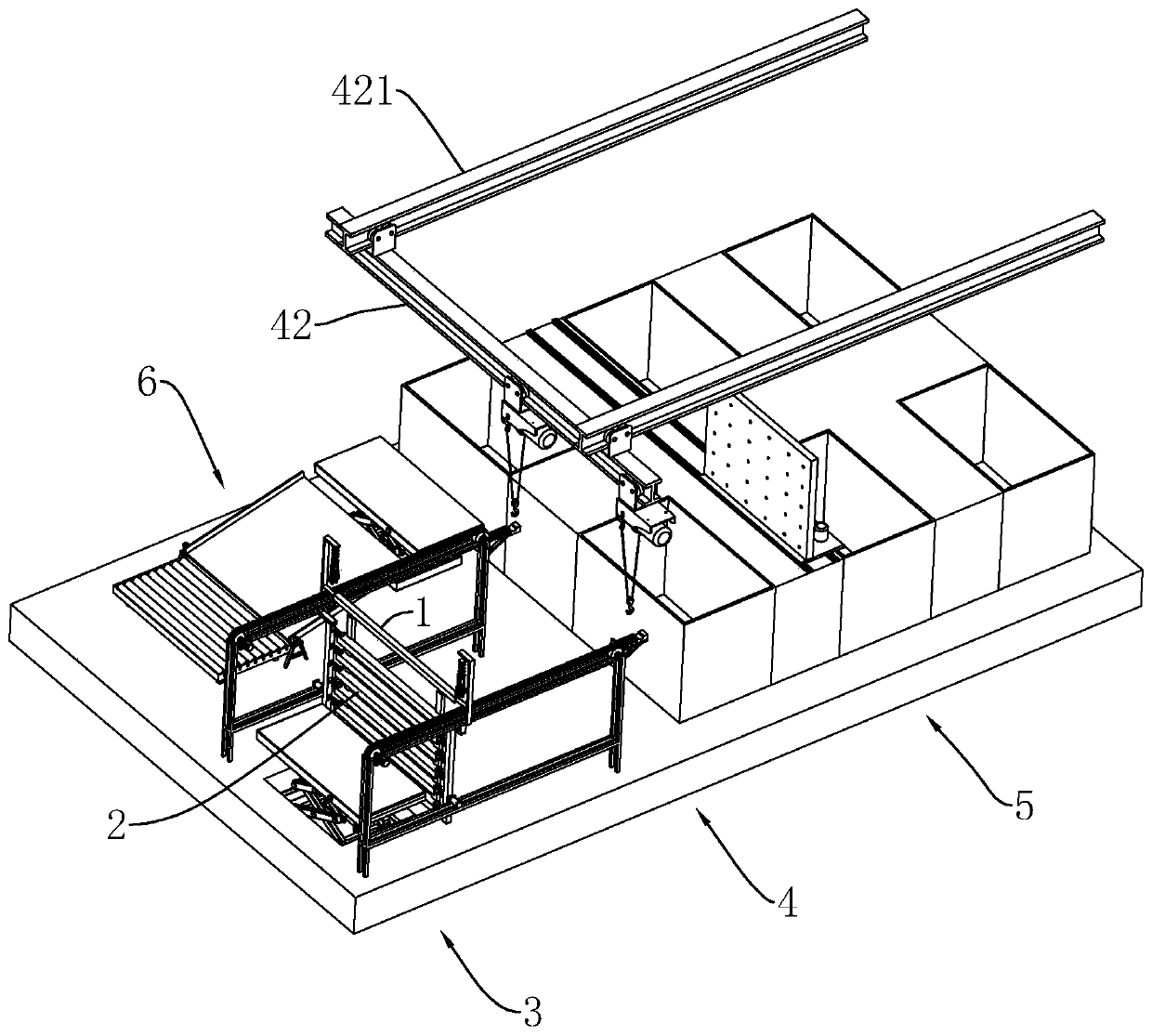

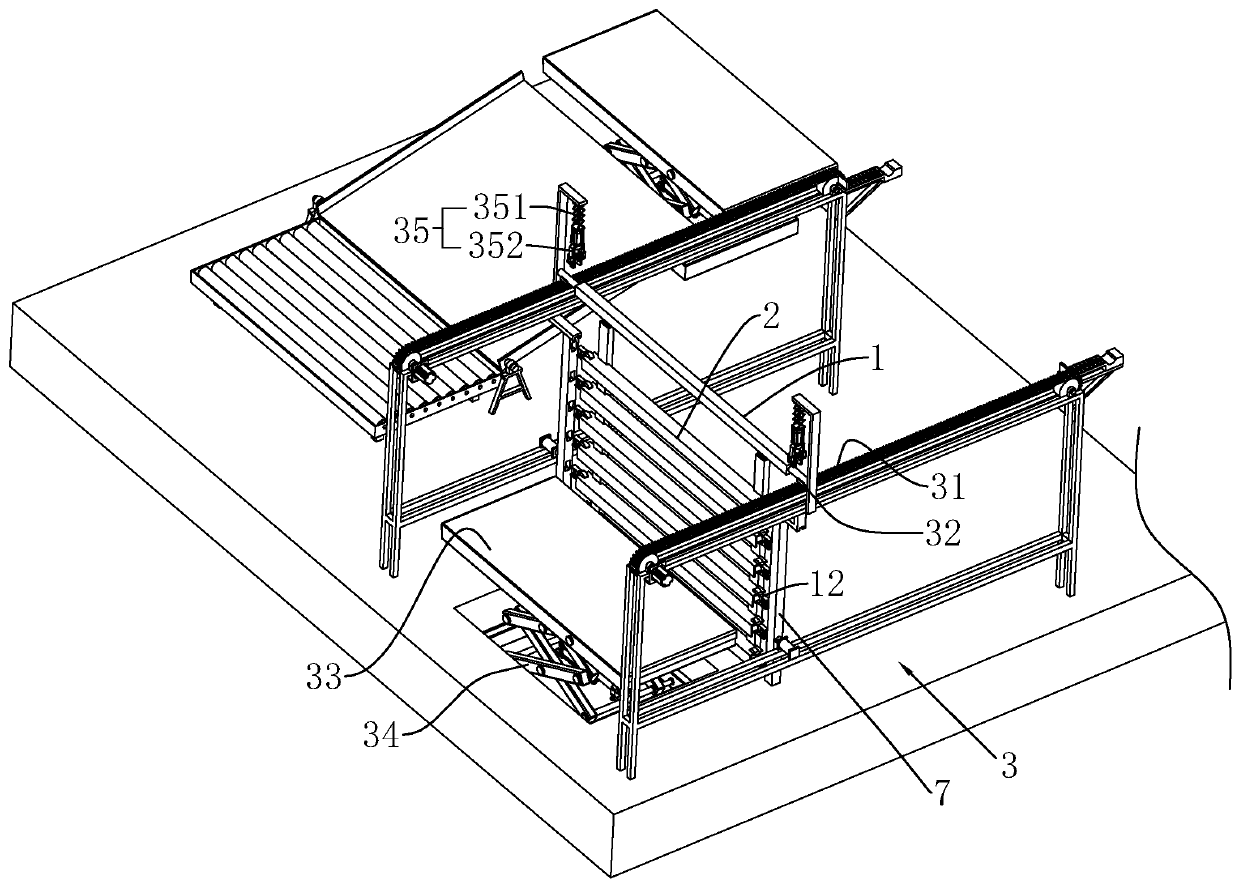

[0071] Embodiment 1: as figure 1 and figure 2 , a profile oxidation production line, including an upper row area 3, a transfer area 4, a treatment area 5 and a lower row area 6. Among them, the role of the upper row area 3 is to realize the loading of the profile 2; the role of the transfer area 4 is to realize the transfer of the transmission line of the profile 2, that is, to migrate from the first floor to the second floor; the role of the lower row area 6 is to realize the profile 2 Processed unloading.

[0072] Such as image 3 , the upper row area 3 includes two rows of transmission chains 31, and the two rows of transmission chains 31 are driven by a gear unit as a whole for transmission. The transmission chain 31 is provided with a joist frame 32 (only one is shown in the figure), and the joist frame 32 supports the carrier beam 1 to realize the transmission of the carrier beam 1 .

[0073] Such as Figure 4 There are two rows of longitudinal rods 11 connected to...

Embodiment 2

[0084] Embodiment 2: A profile oxidation production process using the profile oxidation production line of Example 1, comprising the following steps:

[0085] Step1: In the upper row, select profiles, and remove bad profiles with cracks, peeling, corrosion, air bubbles, bruises, scratches, extrusion marks, scratches, etc. on the surface that cannot be overcome by oxidation;

[0086] Step1.1: The upper row, the material distance is greater than 10%-15% of the profile length, and the material distance is not less than 2 cm; thus it is convenient for heat dissipation;

[0087] Step2: Degreasing, before degreasing, wash in the flowing water pool, pH value 6.5-7.5, wash with water for 15-20 seconds, tilt and lift the liquid control for 20 seconds, subject to the discontinuous dripping of water droplets; the purpose of degreasing is to remove dirt and dust of different degrees , loosen surface oil, residual fingerprints, and natural oxidation film, so that the subsequent alkaline wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com