A high-strength and high-toughness hypoeutectic aluminum-silicon casting alloy and its preparation method

A casting alloy, high-strength and high-toughness technology, which is applied in the field of non-ferrous metal materials, can solve the problems of alloy mechanical properties limitation, poisoned Ti refinement effect, etc., and achieve the effect of improving mechanical properties, improving refinement modification effect, and improving dispersion strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

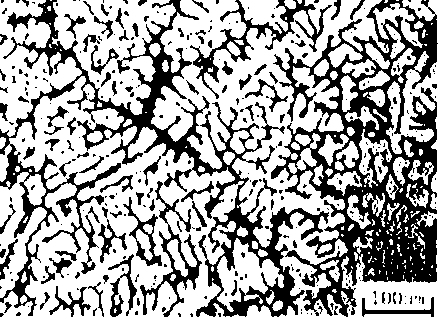

Embodiment 1

[0025] (1) Select Al-20Si, Al-3Be, Al-10Sr, Al-2Sc, Al-5Zr master alloys and pure aluminum, pure magnesium, pure copper as raw materials, according to the chemical composition (mass fraction) of the casting alloy of the present invention Si: 6.8%, Mg: 0.6%, Cu: 0.1%, Be: 0.05%, Sc: 0.2%, Zr: 0.2%, Sr: 0.03%, Fe≤0.1%, and the balance is Al ingredients.

[0026](2) Use resistance furnace and graphite clay crucible for smelting; after drying the prepared alloy raw materials, pure aluminum and Al-20Si, put them into a preheated graphite clay crucible and heat and melt with the furnace; the melt temperature is 690-700℃, and the Heat a graphite bell jar at 300°C and press pure magnesium into it. At 720°C, add pure copper and Al-3Be master alloy and stir evenly for 2-3 minutes.

[0027] (3) When the alloy melt temperature is 730-740°C, use a graphite bell jar preheated to 300°C to press into the aluminum foil-wrapped Cl 6 C 2 Carry out the first refining, the temperature of the mel...

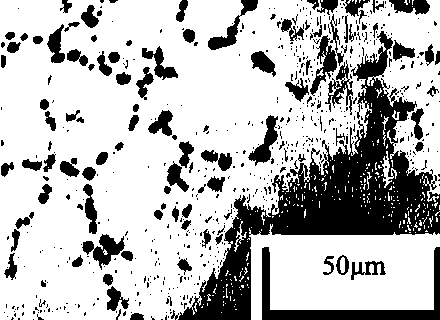

Embodiment 2

[0033] (1) Select Al-20Si, Al-10Sr, Al-2Sc, Al-5Zr master alloys and pure aluminum, pure magnesium, pure copper as raw materials, according to the chemical composition (mass fraction) of the cast alloy of the present invention Si: 6.8%, Mg : 0.6%, Cu: 0.15%, Be: 0.06%, Sr: 0.04%, Sc: 0.3%, Zr: 0.3%, Fe≤0.1%, and the balance is Al ingredients.

[0034] The alloy smelting, the preparation of the alloy sample, and the performance test are all consistent with Example 1. The tensile strength of the alloy sample after heat treatment is 350.3MPa, and the elongation is 6.0%.

Embodiment 3

[0035] Embodiment 3: heat treatment process embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com