A plastic bottle environmental protection label adhesive for automatic labeling machine and its preparation method

A labeling machine and plastic bottle technology, which is applied in the direction of rosin adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problems of unsuitable high-speed automatic labeling, affecting the aesthetics of beer, and poor affinity , to achieve the effects of small temperature difference, low cost, and smooth labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

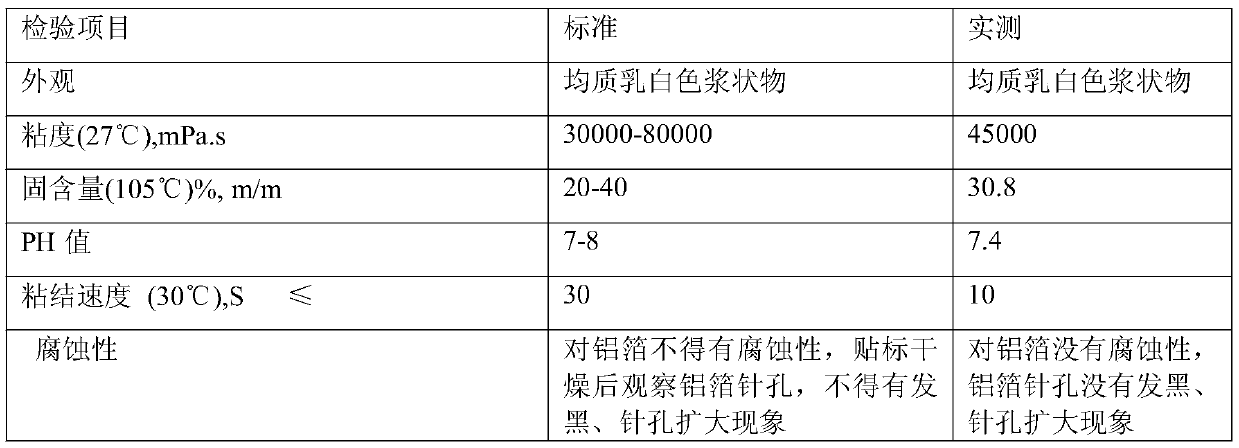

Examples

Embodiment 1

[0023] Embodiment one: the preparation method of plastic bottle environmental protection label adhesive for automatic labeling machine, the steps are:

[0024] (1), 150 kg of deionized water is added to the reaction vessel, then 6 kg of OP-10 is added, and stirred at high speed for 10 minutes;

[0025] (2), add 12 kilograms of rosin, 30 kilograms of methacrylic acid, 35 kilograms of methyl methacrylate, 40 kilograms of ethyl acrylate, and 120 kilograms of butyl acrylate in the above-mentioned reaction vessel in sequence, and continue high-speed stirring for 60-120 minutes;

[0026] (3), dissolve 2 kilograms of ammonium persulfate with 10 kilograms of deionized water, add 9.6 kilograms in the above-mentioned reaction vessel, continue to stir for 10 minutes and make pre-emulsified reaction solution A;

[0027] (4), add 350 kg of deionized water to another reactor, add 80 kg of polyvinyl alcohol, heat up to 85-90°C, keep warm for 2 hours, and cool down to 82±2°C;

[0028] (5), u...

Embodiment 2

[0031] Embodiment two: the preparation method of plastic bottle environmental protection label adhesive for automatic labeling machine, the steps are:

[0032] (1), add 150 kilograms of deionized water to the reaction vessel, then add 6 kilograms of OS, and stir at high speed for 10 minutes;

[0033] (2), add 15 kilograms of rosin, 35 kilograms of methacrylic acid, 35 kilograms of methyl methacrylate, 50 kilograms of ethyl acrylate, and 100 kilograms of butyl acrylate in the above-mentioned reaction vessel in sequence, and continue high-speed stirring for 60-120 minutes;

[0034] (3), dissolve 2 kilograms of ammonium persulfate with 10 kilograms of deionized water, add 9.6 kilograms in the above-mentioned reaction vessel, continue to stir for 10 minutes and make pre-emulsified reaction solution A;

[0035] (4) Add 350 kg of deionized water to another reactor, add 100 kg of polyvinyl alcohol, heat up to 85-90°C, keep warm for 2 hours, and cool down to 82±2°C;

[0036] (5), und...

Embodiment 3

[0039] Embodiment three: the preparation method of plastic bottle environmental protection label adhesive for automatic labeling machine, the steps are:

[0040] (1), 150 kg of deionized water is added to the reaction vessel, then 6 kg of OP-10 is added, and stirred at high speed for 10 minutes;

[0041] (2), add 50 kilograms of rosin, 100 kilograms of methacrylic acid, 60 kilograms of methyl methacrylate, 800 kilograms of ethyl acrylate, and 200 kilograms of butyl acrylate in the above-mentioned reaction vessel in sequence, and continue high-speed stirring for 60-120 minutes;

[0042] (3), dissolve 10 kilograms of ammonium persulfate with 10 kilograms of deionized water, add 9.6 kilograms in the above-mentioned reaction vessel, continue to stir for 10 minutes and make pre-emulsified reaction solution A;

[0043] (4), add 400 kg of deionized water to another reactor, add 200 kg of polyvinyl alcohol, heat up to 85-90°C, keep warm for 2 hours, and cool down to 82±2°C;

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com