Hydrophobic graphene solvent-free epoxy underwater curing coating and preparation method thereof

An underwater curing and graphene technology, applied in epoxy resin coatings, coatings, etc., can solve problems such as poor adhesion, poor flexibility of paint films, and difficulties in underwater construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of a kind of hydrophobic type graphene solvent-free epoxy underwater curing coating described in the present embodiment is made from the raw material of following percentage by weight:

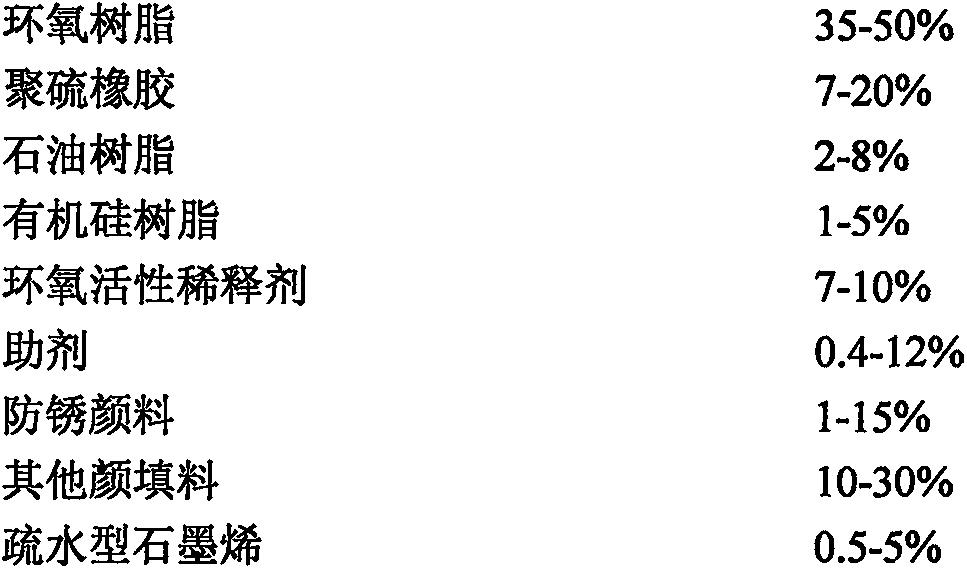

[0019] Component A

[0020]

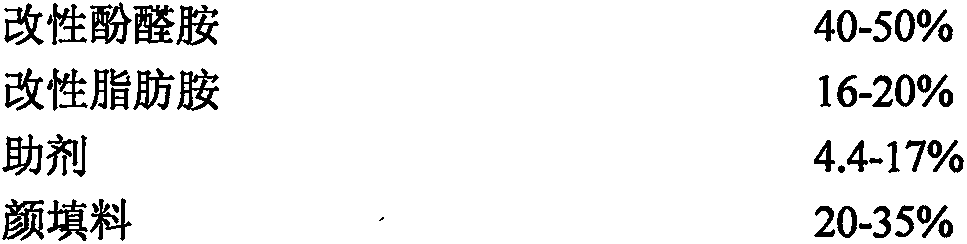

[0021] Component B

[0022]

[0023] Preparation method: (1) Put each raw material in component A into the tank one by one, stir rapidly to disperse, and grind to 50 μm to obtain component A. (2) Put each raw material in component B into the tank one by one, stir rapidly to disperse, and grind to 50 μm to obtain component B. (3) Mix component A and component B uniformly according to the weight ratio of 100:38 to obtain a hydrophobic graphene solvent-free epoxy underwater curing coating.

[0024] How to use: Remove floating rust on steel surface, remove dirt on concrete surface, and then brush, roll or scrape the mixed paint on the surface of the substrate.

Embodiment 2

[0026] The preparation method of a kind of hydrophobic type graphene solvent-free epoxy underwater curing coating described in the present embodiment is made from the raw material of following percentage by weight:

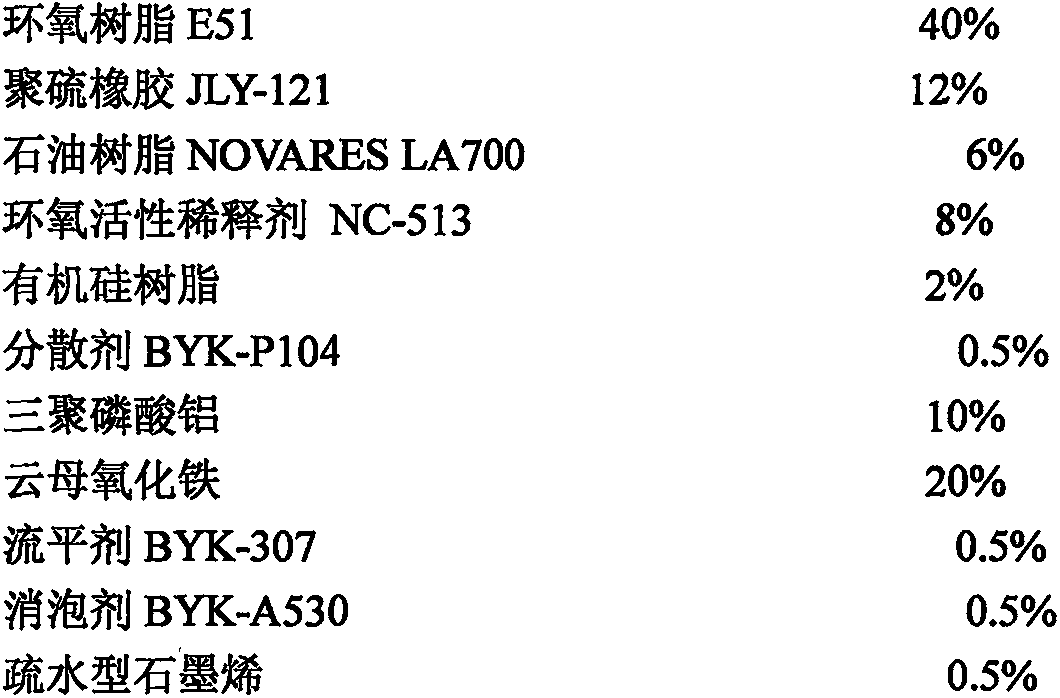

[0027] Component A

[0028]

[0029] Component B

[0030]

[0031] Preparation process and method of use are the same as in Example 1

Embodiment 3

[0033] The preparation method of a kind of hydrophobic type graphene solvent-free epoxy underwater curing coating described in the present embodiment is made from the raw material of following percentage by weight:

[0034] Component A

[0035]

[0036] Component B

[0037]

[0038]

[0039] Preparation process and method of use are the same as in Example 1

[0040] Table 1 performance test results

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com