Method for removing oxime through catalysis of tellurium

A catalyst and oxidant technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as high cost, achieve high yield, safe operation, and reduce reaction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

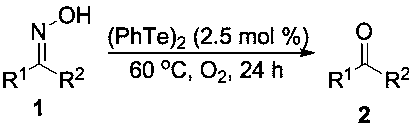

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

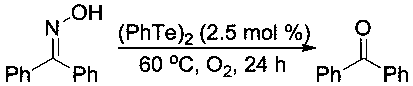

[0015] Add 1 mmol benzophenone oxime and 0.025 mmol diphenyl ditelluride into the reaction test tube, fill it with oxygen, connect it with an oxygen bulb, and heat at 60°C for 24 hours. The product benzophenone was separated by column chromatography with a yield of 92%.

[0016] The above reaction formula is as follows:

[0017]

Embodiment 2

[0019] Other conditions are the same as in Example 1, and the reactions under different solvents are checked, and the experimental results are shown in Table 1.

[0020] Table 1 Inspection of different solvents

[0021] Numbering

[0022] From the above results, it can be seen that the yield of the reaction is better in various solvents or without a solvent, and from the consideration of cost, safety and environmental protection, the condition of solvent-free is preferred.

Embodiment 3

[0024] Other conditions are the same as in Example 1, and the reactions at different temperatures are checked, and the experimental results are shown in Table 2.

[0025] The inspection of different reaction temperatures in table 2

[0026] Numbering

[0027] From the above results, it can be known that the reaction temperature is preferably 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com