A kind of surface-modified reactive electrochemical membrane and preparation method thereof

An electrochemical and reactive technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of difficult to handle, high concentration of refractory organic matter, poor biodegradability, etc., to improve the content, strengthen oxidation, activity The effect of point increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

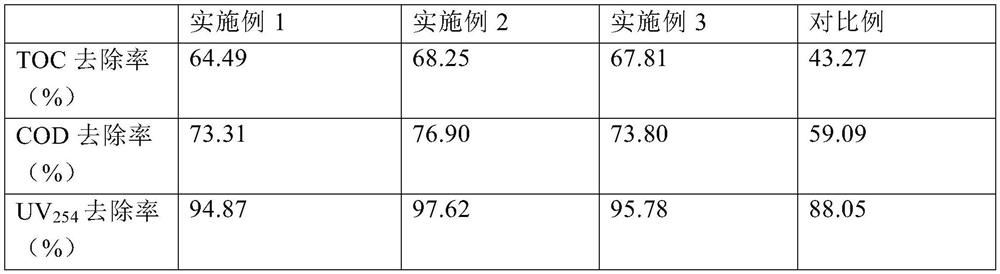

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a method for preparing a reactive electrochemical film whose surface has been modified: specifically including:

[0031] 1) High-purity Ti 4 o 7 The powder and additives are mixed and dissolved in a solvent to form a slurry;

[0032] 2) After vacuum mud refining and tube extrusion molding, the green body is obtained;

[0033] 3) The green body is modified by cooling, drying, and impregnating the salt solution of the precursor of the modifying element, and then adopts temperature-programmed calcination to shape it.

[0034] Among them, the additives used in the pulping process of the above preparation method include one or more of ethylene carbonate, dimethyl carbonate, perfluorosulfonic acid, and sodium carboxymethyl cellulose, and the solvent uses N-methylpyrrolidone, One or more of dimethylacetamide and N-N dimethylformamide. The mass ratio of base powder, additive and solvent is (5-15): 1:1, preferably (8-10):...

Embodiment 1

[0048] (1) Mixing and pulping: the high-purity Ti 4 o 7 Powder, ethylene carbonate (EC) and perfluorosulfonic acid (Nafion) according to mass ratio to Ti 4 o 7 :EC:Nafion=8:1:1, mix and dissolve in 500mL N-methylpyrrolidone (NMP), stir slowly, and make a slurry.

[0049] (2) Vacuum mud refining: use a single-axis vacuum mud refining machine with a rotating speed of 20r / min, and vacuum mud refining for 30min.

[0050] (3) Tube extrusion: set the pressure of the tube extrusion machine to 20MPa, squeeze the slurry into the calibrating sleeve, the flow rate of dry nitrogen passing through the calibrating sleeve is 3m / s, and obtain the membrane body after 3 hours in the cooling water circulation system.

[0051] (4) Drying: the membrane body is placed in an oven, and dried at 75° C. for 72 hours.

[0052] (5) Green body modification: weigh 40g CoCl 2 ·6H 2 O, 30gSbCl 3 , TaCl 3 Mix and dissolve in 100mL high-purity water, add 1mol / L NaCO 3 Adjust the pH to 8, keep it at ro...

Embodiment 2

[0058] (1) Mixing and pulping: the high-purity Ti 4 o 7 Powder, dimethyl carbonate (DMC) and sodium carboxymethylcellulose (CMC) according to mass ratio to Ti 4 o 7 :DMC:CMC=8:1:1 ratio mixed and dissolved in 500mL dimethylacetamide (DMAC), stirred slowly, prepared into a slurry.

[0059] (2) Vacuum mud refining: use a single-axis vacuum mud refining machine with a speed of 25r / min, and vacuum mud refining for 30 minutes.

[0060] (3) Tube extrusion: set the pressure of the tube extrusion machine to 40MPa, squeeze the slurry into the calibrating sleeve, and pass the flow rate of dry nitrogen in the calibrating sleeve to 6m / s, and obtain the membrane body after 4 hours in the cooling water circulation system.

[0061] (4) Drying: the membrane blank is placed in an oven, and dried at 80° C. for 48 hours.

[0062] (5) Green body modification: weigh 45gTaCl 5 , SbCl 3 , 40g IrCl 3 and 8mLTiCl 4 Mix and dissolve in 150mL high-purity water, add 3mol / L NaCO 3 Adjust the pH t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com