Emulsion filtration system and method for cold continuous rolling of stainless steel

A filtration system and emulsion technology, applied in the field of emulsion filtration system for stainless steel cold rolling, can solve the problems of low efficiency of oil separation device and poor separation effect, and achieve long-term high-efficiency and stable operation, good filtration effect, and guaranteed rolling. quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

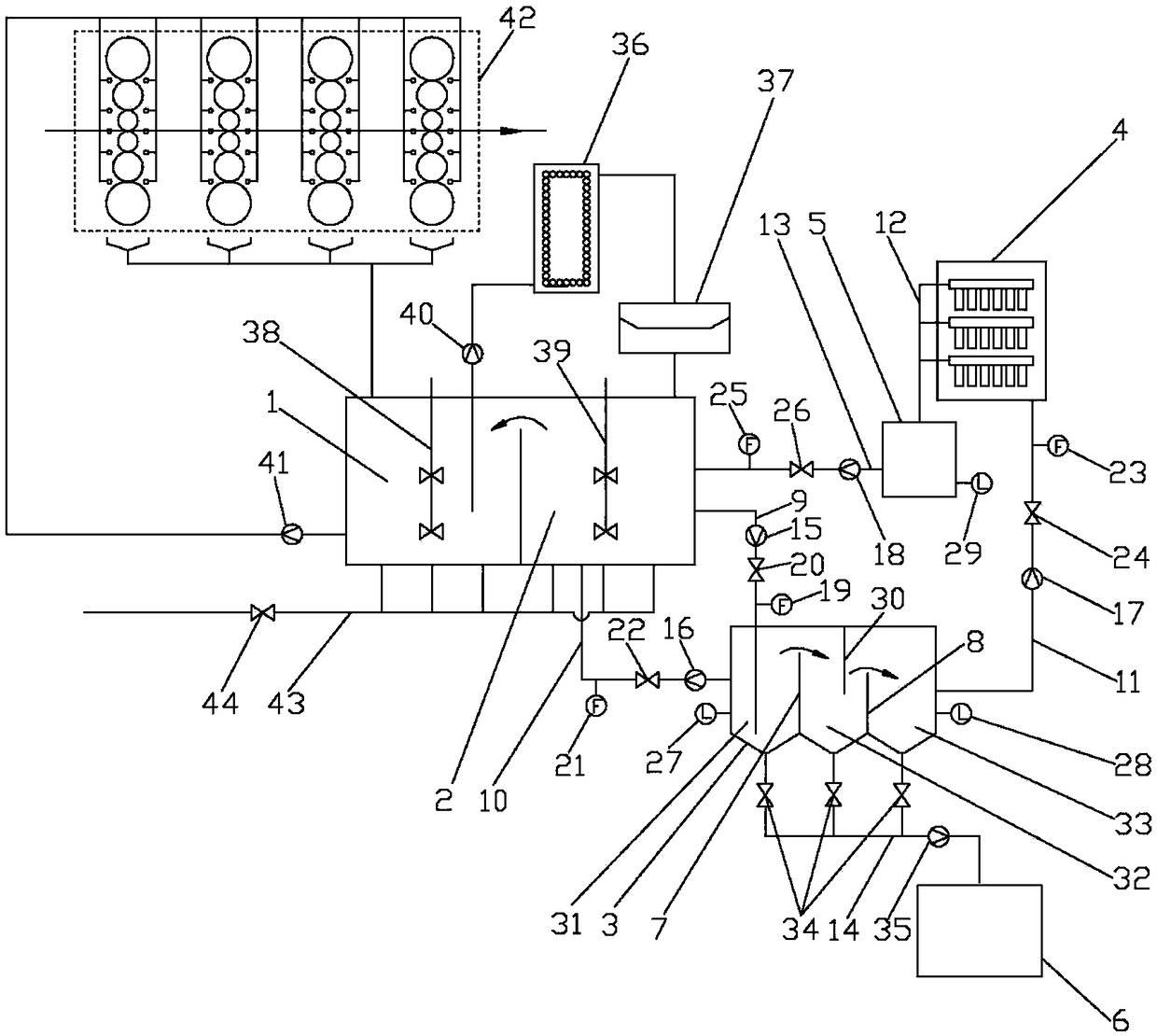

[0035] Such as figure 1 A stainless steel cold continuous rolling emulsion filtration system shown includes a dirty emulsion tank 1, a filter device, a clean emulsion tank 2, a static tank 3, a rolling oil filter 4, a clean oil tank 5, a sewage tank 6 and Filtration device; The first stirrer 38 is established in the described dirty emulsion tank 1, and the dirty emulsion tank 1 is communicated with the inlet of the filter device, and the outlet of the filter device is communicated with the clean emulsion tank 2; the clean emulsion tank 2 is provided with the first Two stirrers 39, the clean emulsion tank 2 is communicated with the nozzle at the continuous rolling mill 42 through the supply pump 41; the bottom of the dirty emulsion tank 1 and the bottom of the clean emulsion tank 2 are respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com