Method for determining 12 metal elements in soil and sediment

A metal element and sediment technology, applied in the field of soil environmental protection detection, can solve problems such as slow air-drying process, incorrect or less dripping by test personnel, and constant volume deviation, so as to reduce the use of consumables, ensure stability and accuracy, and reduce The effect of constant volume error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for measuring 12 metal elements in soil and sediment, comprising the steps of:

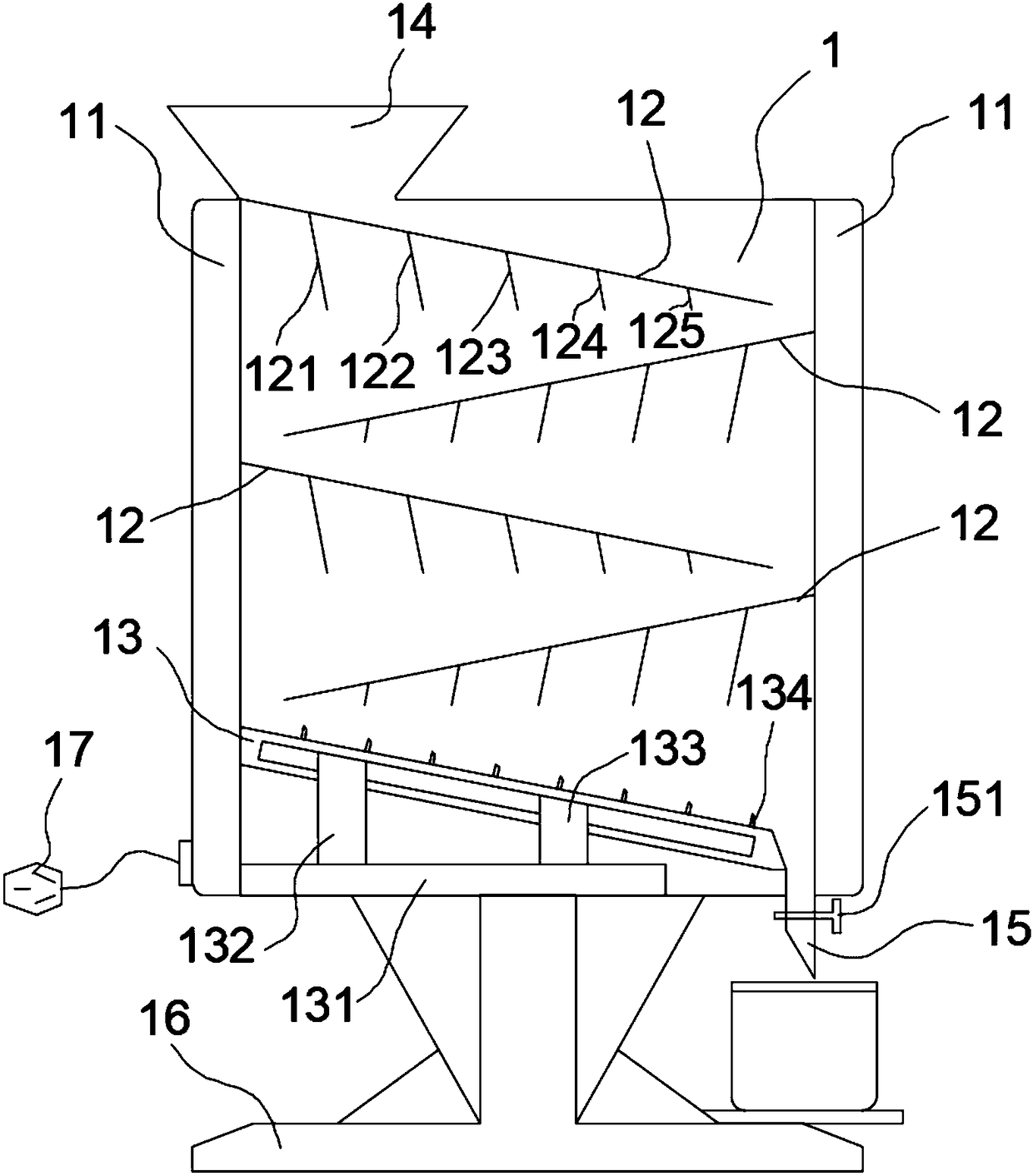

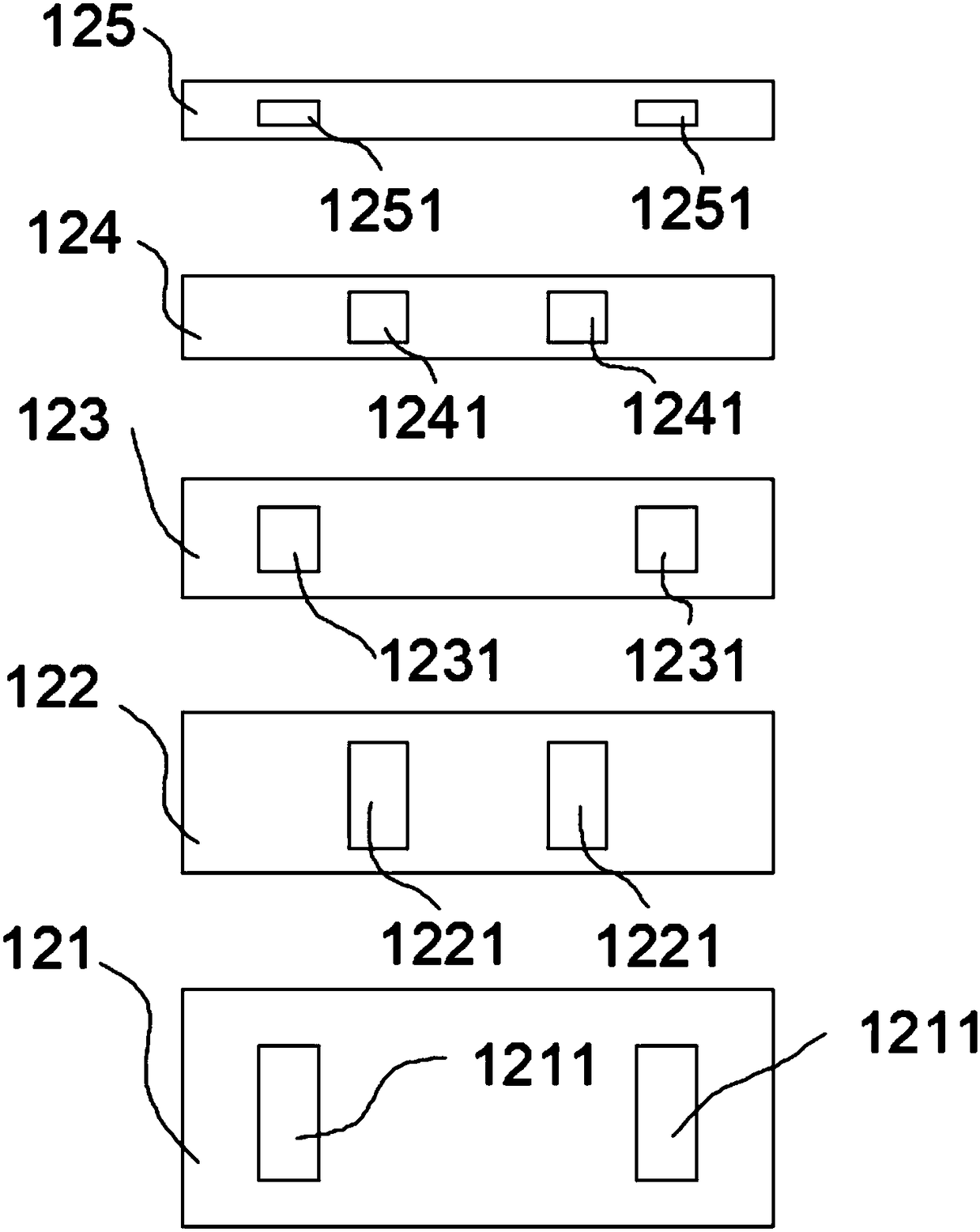

[0037] S1: Collect the soil to be tested, put the soil to be tested into the feed port 14 of the soil treatment device 1, and realize the air-drying process through the cooperation of the fan 11, the air-drying plate 12 and five air-collecting plates, and then drive the sorting by the vibration motor 131 Plate 13 and through baffle plate 134 and gravity, soil is sorted; The air-drying treatment time is 10 minutes, and the sorting treatment time is 5 minutes;

[0038] S2: After the soil sample is collected and processed, the processed soil sample is put into a grinder and pulverized to a 180 mesh sieve, and put into a dry and sealed sample bottle for sealed preservation;

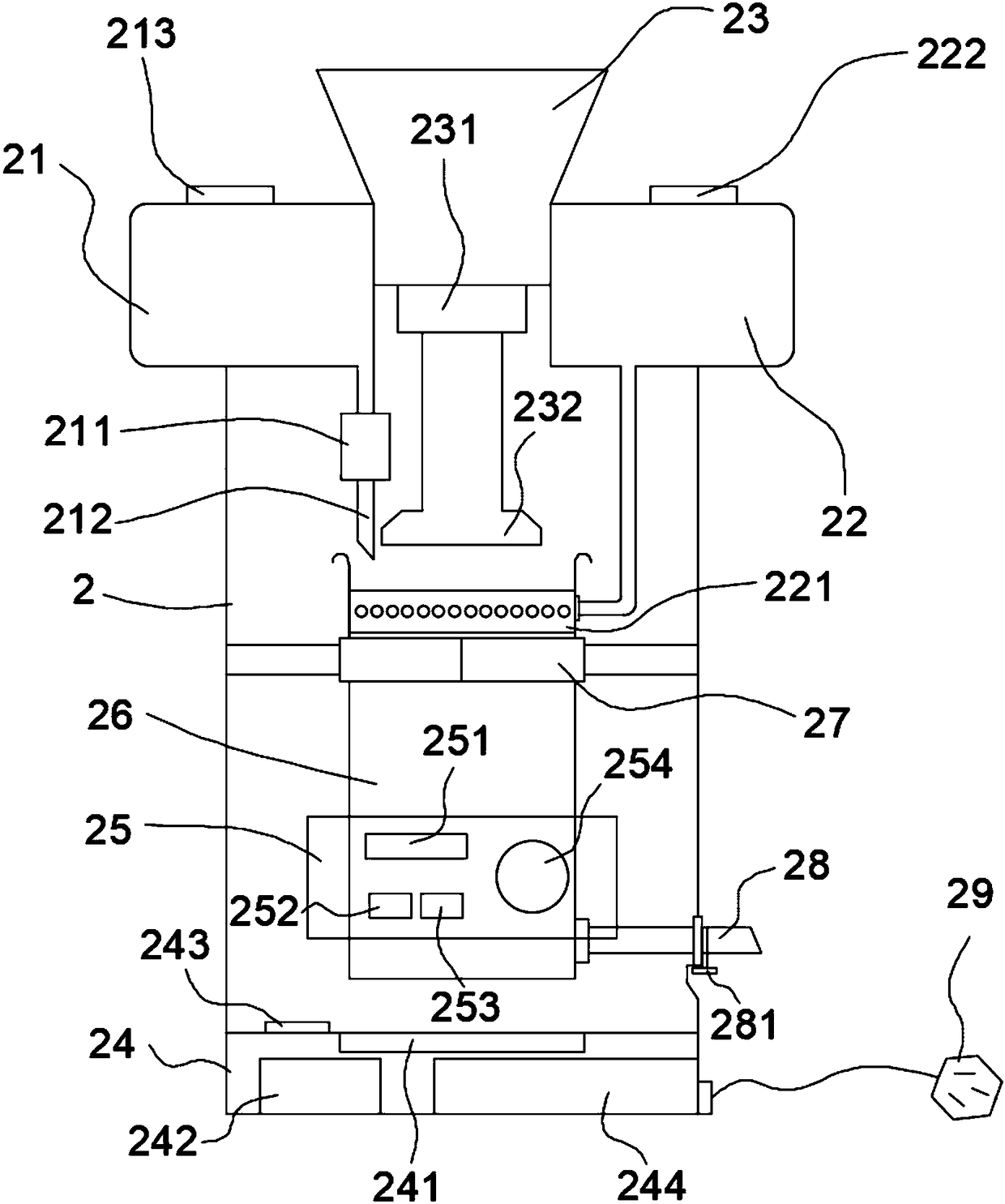

[0039] S3: 1 g of the soil sample in the sample bottle is placed in the soil sample box 23 of the digestion device 2, and the soil sample is dropped into a 50 ml polytetrafluoroethylene beaker by vibrating ring 23...

Embodiment 2

[0051] A method for measuring 12 metal elements in soil and sediment, comprising the steps of:

[0052] S1: Collect the soil to be tested, put the soil to be tested into the feed port 14 of the soil treatment device 1, and realize the air-drying process through the cooperation of the fan 11, the air-drying plate 12 and five air-collecting plates, and then drive the sorting by the vibration motor 131 Plate 13 and through baffle plate 134 and gravity, soil is sorted; The air-drying treatment time is 15 minutes, and the sorting treatment time is 10 minutes;

[0053] S2: After the soil sample is collected and processed, the processed soil sample is put into a grinder and pulverized to a 180 mesh sieve, and put into a dry and sealed sample bottle for sealed preservation;

[0054] S3: 2 g of the soil sample in the sample bottle is placed in the soil sample box 23 of the digestion device 2, and the soil sample is dropped into a 50 ml polytetrafluoroethylene beaker by vibrating ring 2...

Embodiment 3

[0066] A method for measuring 12 metal elements in soil and sediment, comprising the steps of:

[0067] S1: Collect the soil to be tested, put the soil to be tested into the feed port 14 of the soil treatment device 1, and realize the air-drying process through the cooperation of the fan 11, the air-drying plate 12 and five air-collecting plates, and then drive the sorting by the vibration motor 131 Plate 13 and through baffle plate 134 and gravity, soil is sorted; The air-drying treatment time is 20 minutes, and the sorting treatment time is 15 minutes;

[0068] S2: After the soil sample is collected and processed, the processed soil sample is put into a grinder and pulverized to a 180 mesh sieve, and put into a dry and sealed sample bottle for sealed preservation;

[0069]S3: get the soil sample 1-3g in the sample bottle and place it in the soil sample box 23 of the digestion device 2, and the soil sample will fall into the 50ml polytetrafluoroethylene beaker by the vibratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com