Collection box of 630-degree advanced ultra-supercritical boiler

A technology for ultra-supercritical boilers and headers, which is applied to components of steam boilers, boiler drums/box headers, steam boilers, etc. The steam oxidation performance cannot meet the use requirements and other problems, so as to achieve excellent steam oxidation resistance, reduce the wall thickness of the header, and reduce the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

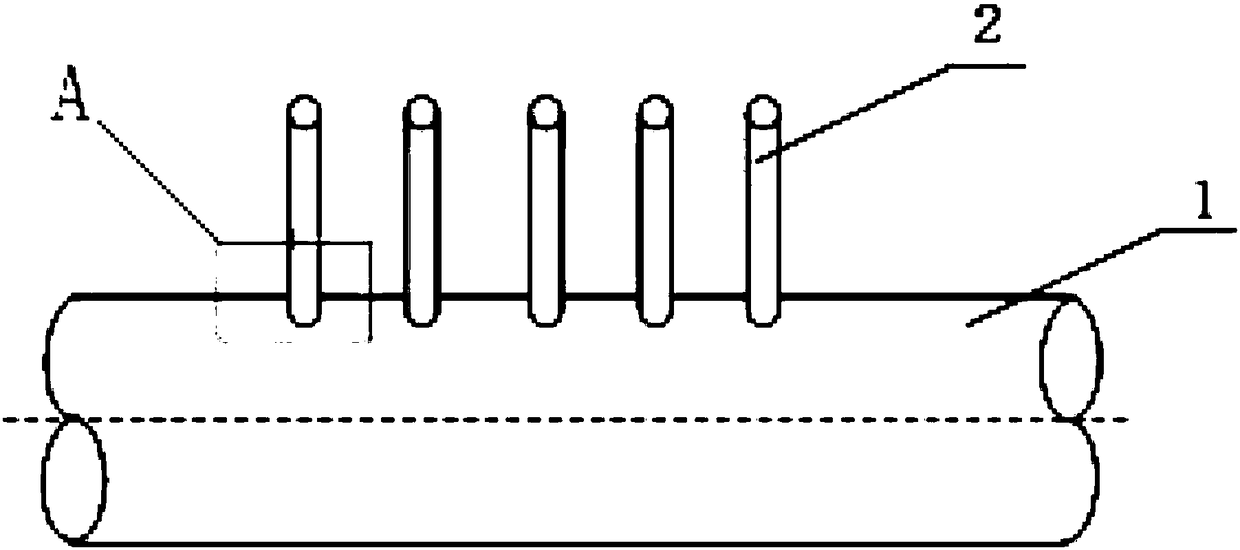

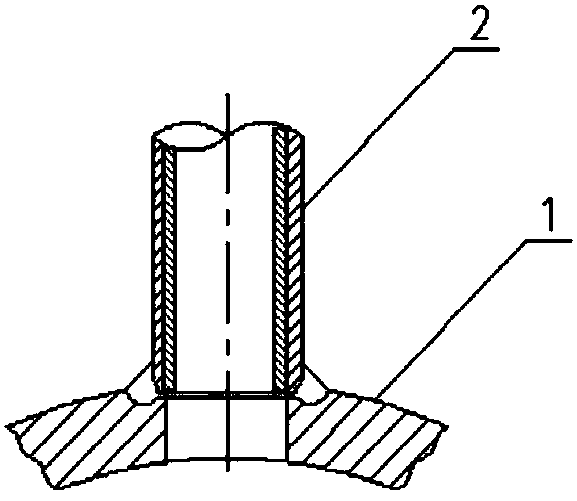

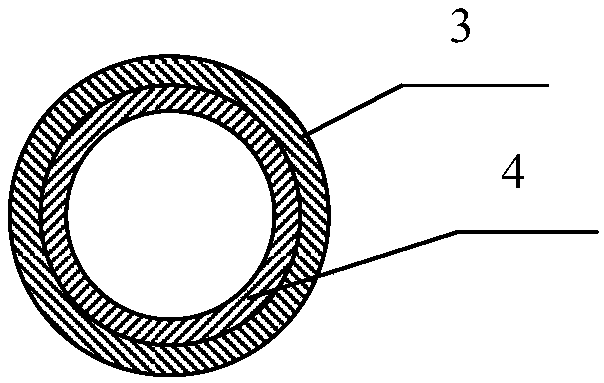

[0021] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the header of a 630°C advanced ultra-supercritical boiler in this embodiment includes a header body 1 and a header pipe joint 2, and a set of header pipe joints are welded on the header body 1 2. One end of the header pipe joint 2 is welded to the high-temperature heating surface tube of the boiler. The high-temperature heating surface of the boiler is the boiler superheater and boiler reheater. The other end of the header pipe joint 2 and the header body 1 adopt a complete Penetrating fillet seam welding, the header body 1 is made of G115 large-diameter pipe, and the header pipe joint 2 is made of G115+GH984G small-diameter composite steel pipe.

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 Describe this embodiment, the header of a 630°C advanced ultra-supercritical boiler in this embodiment, in the G115 large-diameter tube alloy composition used in the header body 1, the Cr content is 8.0% to 10.0%, and the W content is 2.0%. ~4.0%, the Co content is 2.0%~3.5%, and the G115 metallographic structure of the material is tempered martensite.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 Describe this embodiment, the header of a 630°C advanced ultra-supercritical boiler in this embodiment, in the G115 large-diameter tube alloy composition used in the header body 1, the Cr content is 8.0%, and the W content is 2.0% , the Co content is 2.0%, and the G115 metallographic structure of the material is tempered martensite.

[0024] Specific implementation mode four: combination figure 1 Description of this embodiment, the header of a 630°C advanced ultra-supercritical boiler in this embodiment, in the G115 large-diameter tube alloy composition used in the header body 1, the Cr content is 10.0%, the W content is 4.0%, and the Co content 3.5%, the G115 metallographic structure of the material is tempered martensite.

[0025] Specific implementation mode five: combination figure 1 Description of this embodiment, the header of a 630°C advanced ultra-supercritical boiler in this embodiment, in the G115 lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com