Smart numerically controlled pipeline oil heater

A pipeline oil and heater technology, applied in pipeline heating/cooling, electric heating devices, pipeline systems, etc., can solve the problems of cumbersome maintenance and replacement, and can only monitor fixed-point flow, and achieve high measurement accuracy, good energy-saving effect, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

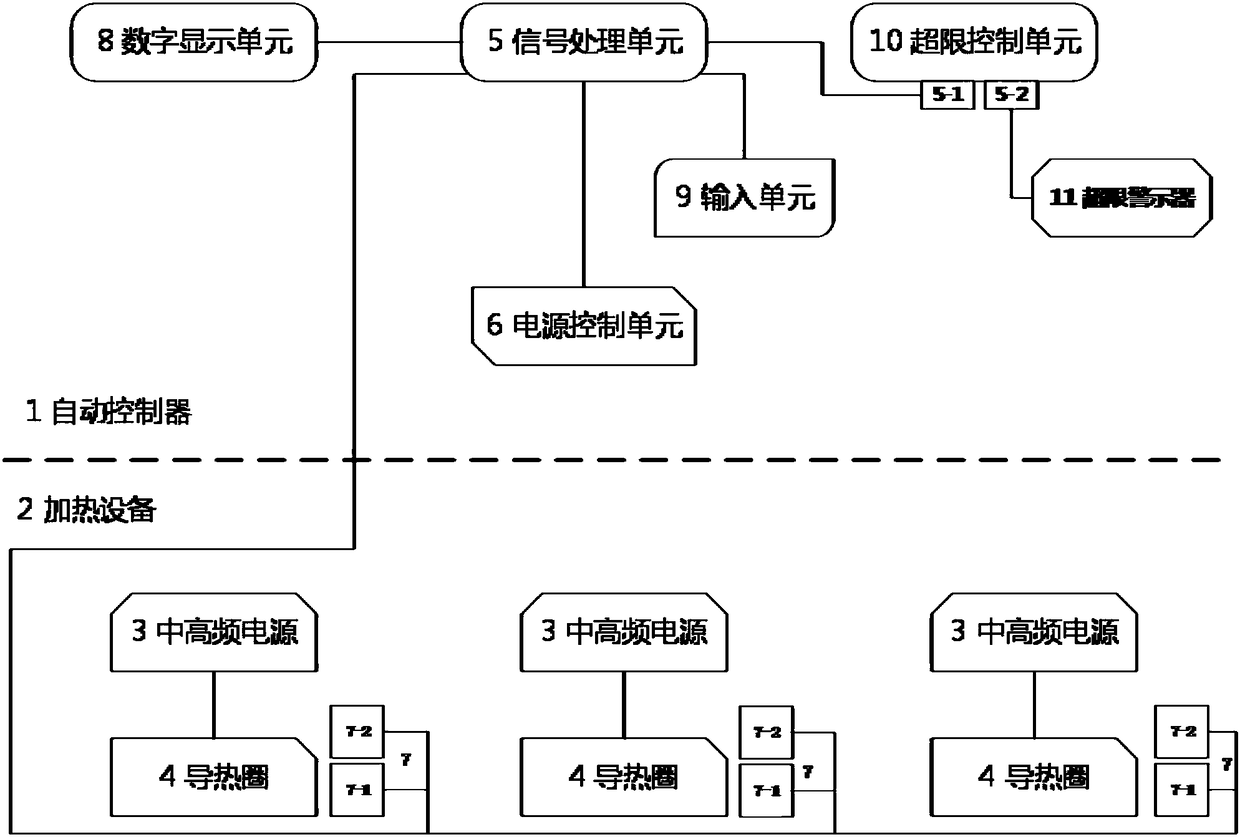

[0051] see figure 1 . The intelligent numerical control pipeline oil heater of this embodiment includes an automatic controller 1 and multiple sets of heating equipment 2 .

[0052]The heating device includes a medium-high frequency power supply 3, a conductive coil 4 and multiple pairs of temperature sensors 7, and the output end of the medium-high frequency power supply 3 is electrically connected to the conductive coil 4;

[0053] The automatic controller 1 includes a signal processing unit 5 and a power control unit 6;

[0054] The paired temperature sensor 7 includes a near-end temperature sensor 7-1 arranged near the conductive coil 4 and a remote temperature sensor 7-2 arranged at a position away from the conductive coil, and the output terminal of the temperature sensor 7 is connected to the The input terminals of the signal processing unit 5 are connected;

[0055] The output end of the signal processing unit 5 is connected to the input end of the power control uni...

Embodiment 2

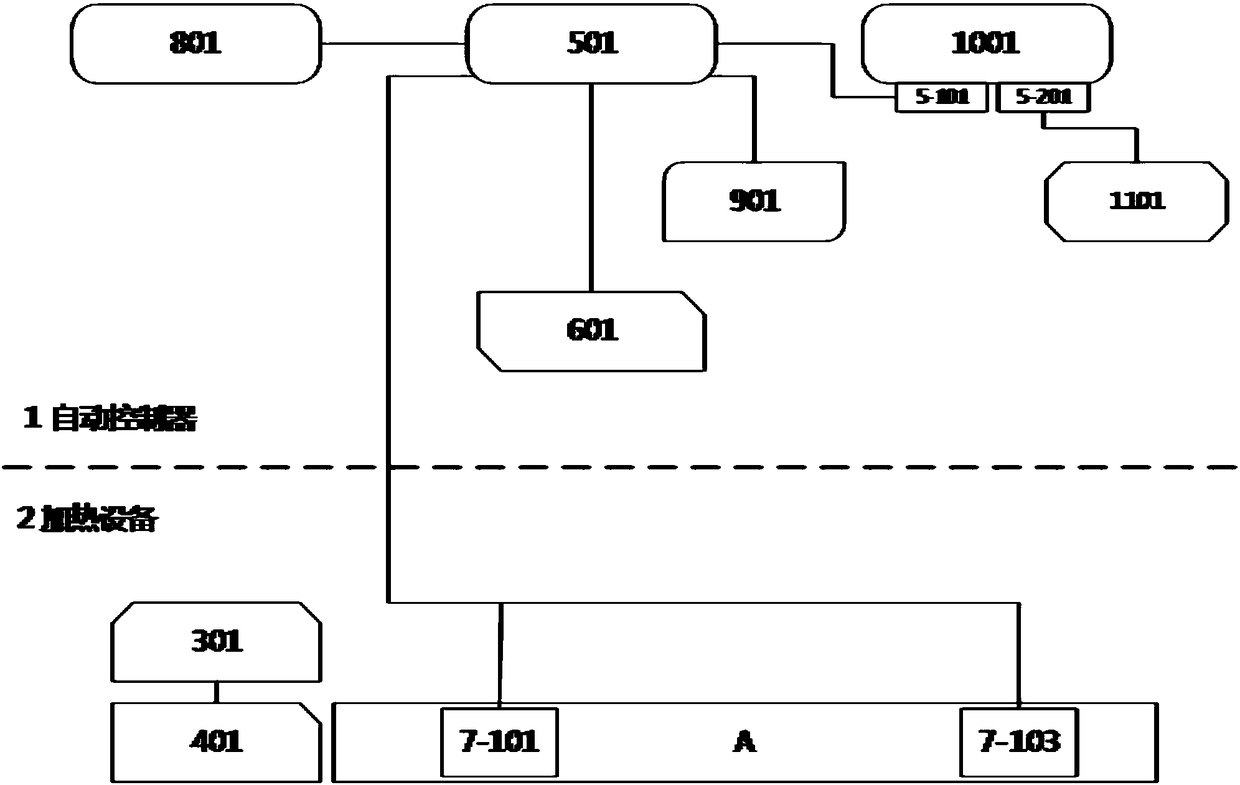

[0057] see figure 2 . When the intelligent numerical control pipeline oil heater performs flow measurement, it shall be implemented as follows.

[0058] The conductive coil 401 is set on the upstream and downstream of the pipeline, and the proximal temperature sensor 7-101 located at the most upstream of the pipeline and the proximal temperature sensor 7-103 located at the most downstream are used as the upstream and downstream temperature sensors. Start the automatic controller 1 to make the conductive coil 401 start heating, and provide a certain amount of heat Q within a specified time.

[0059] The signal processing unit 501 obtains the temperature values of the upstream and downstream temperature sensors 7-101 and 7-103, and calculates the difference ΔT between them F . Input the specific heat capacity c of the measured oil to the automatic controller 1 through the input unit 901, and then the signal processing unit 5 according to the formula Q=c×m×ΔT F Perform cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com