Environment-friendly oil removal agent

A degreasing agent, environmental protection technology, applied in the field of environmental protection degreasing agent, can solve the problems of degreasing agent containing phosphorus, long cleaning time, poor effect, etc., to achieve easy biodegradation, good degreasing effect, good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

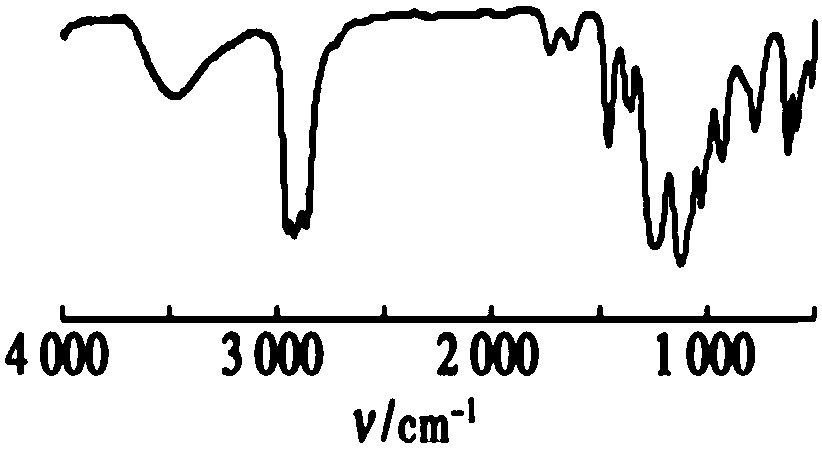

Image

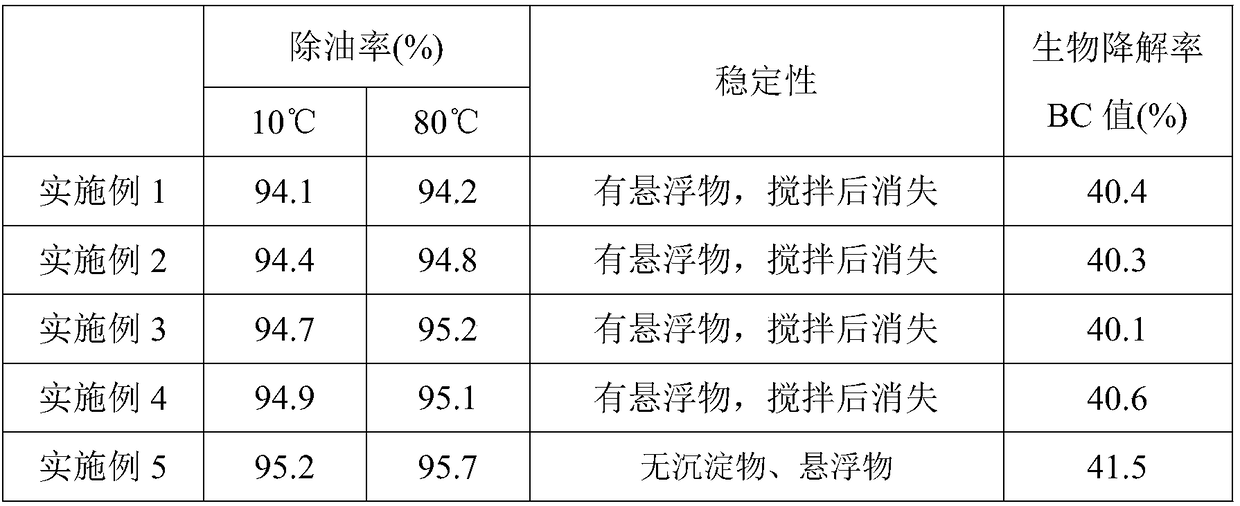

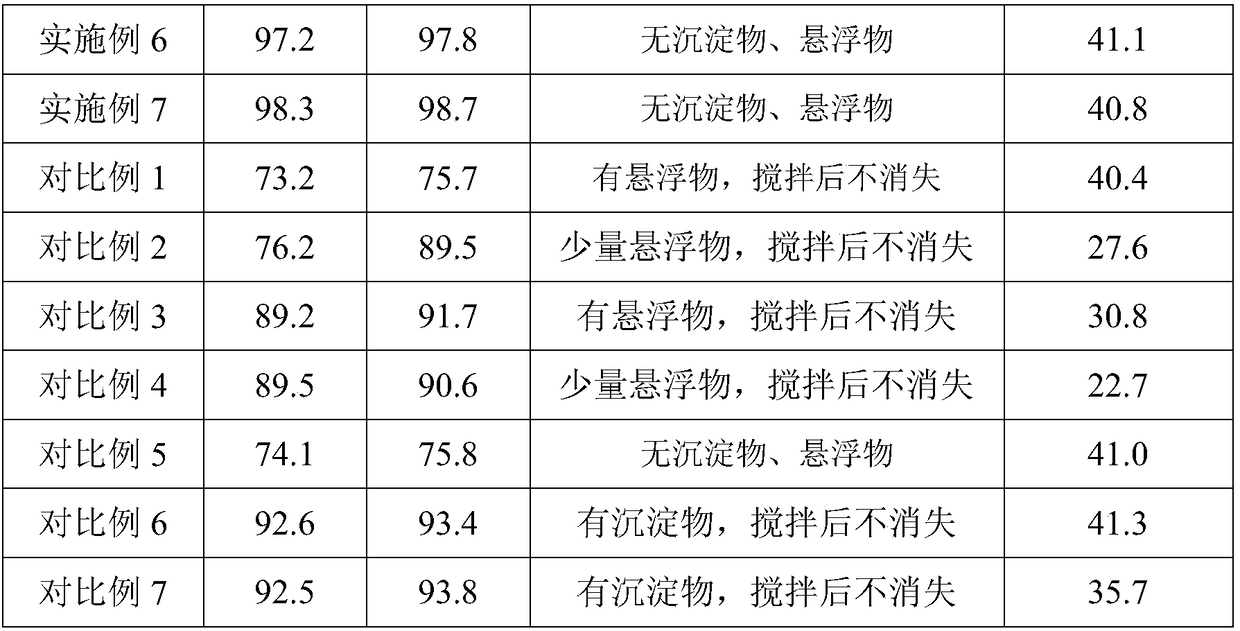

Examples

preparation example Construction

[0033] The preparation method of described isomerism alcohol polyoxyethylene ether sodium sulfate, comprises the following steps at least:

[0034]a. Add 3,5,5-trimethyl-1-hexanol and catalyst magnesium hydroxide into the pressure reactor, connect the propylene oxide metering tank to the pressure reactor, replace the air in the reactor with nitrogen for 3 times, and wait for the reactor to When the temperature rises to 115-120°C, propylene oxide is introduced, the molar ratio of 3,5,5-trimethyl-1-hexanol to propylene oxide is 1:1, the passage is completed within 0.5 hours, and the reaction is continued for 2 hours; The temperature of the kettle rises to 175-180°C, and ethylene oxide is introduced into it. The molar ratio of 3,5,5-trimethyl-1-hexanol and ethylene oxide is 1:5, and the passage is completed within 3 hours. Continue to react for 1h. After the reaction is completed, cool and release the pressure to obtain a colorless and transparent product a. The mass of magnesi...

Embodiment 1

[0095] Embodiment 1 provides a kind of environment-friendly degreasing agent, by weight, at least comprises the following components: 5 weight parts of isomeric alcohol polyoxyethylene ether sodium sulfate, 3 weight parts of ricinoleic acid methyl ester ethoxylate, coconut oil 2 parts by weight of oleic acid diethanolamide, 1 part by weight of dodecyl dimethyl benzyl ammonium chloride, 2 parts by weight of lauryl betaine, 5 parts by weight of succinic acid, 3 parts by weight of citric acid, 1 part by weight of hydrochloric acid parts by weight, 1 part by weight of hydrofluoric acid, and 65 parts by weight of deionized water.

[0096] The preparation method of described isomerism alcohol polyoxyethylene ether sodium sulfate, comprises the following steps at least:

[0097] a. Add 3,5,5-trimethyl-1-hexanol and catalyst magnesium hydroxide into the pressure reactor, connect the propylene oxide metering tank to the pressure reactor, replace the air in the reactor with nitrogen for...

Embodiment 2

[0106] Embodiment 2 provides a kind of environment-friendly degreasing agent, by weight, at least comprises the following components: 13 parts by weight of isomeric alcohol polyoxyethylene ether sodium sulfate, 12 parts by weight of ricinoleic acid methyl ester ethoxylate, coconut oil 5 parts by weight of diethanolamide oleic acid, 4 parts by weight of dodecyl dimethyl benzyl ammonium chloride, 3 parts by weight of lauryl betaine, 12 parts by weight of succinic acid, 7 parts by weight of citric acid, 3 parts by weight of hydrochloric acid parts by weight, 2 parts by weight of hydrofluoric acid, and 85 parts by weight of deionized water.

[0107] The preparation method of described isomeric alcohol polyoxyethylene ether sodium sulfate is with embodiment 1.

[0108] The preparation method of described environment-friendly degreasing agent is the same as embodiment 1.

[0109] The ricinoleic acid methyl ester ethoxylate was purchased from China Light Daily Chemical Technology Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com