Preparation method and application of PCAMT (polymeric aluminium magnesium titanium chloride)

A technology of polyaluminum magnesium chloride and aluminum chloride, which is applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The problem of large dosage and other problems can achieve the effect of good turbidity removal and decolorization, good coagulation effect and fast floc settling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of polyaluminium-magnesium-titanium chloride, which comprises the following steps:

[0026] (1) Take aluminum chloride hexahydrate and add deionized water to fully stir and dissolve to obtain a colorless transparent solution, prepare an aluminum chloride solution with a concentration of 0.1 to 0.3mol / L, take magnesium chloride hexahydrate and add deionized water to fully stir and dissolve to obtain Colorless and transparent solution, prepared as a magnesium chloride solution with a concentration of 0.05-0.2mol / L;

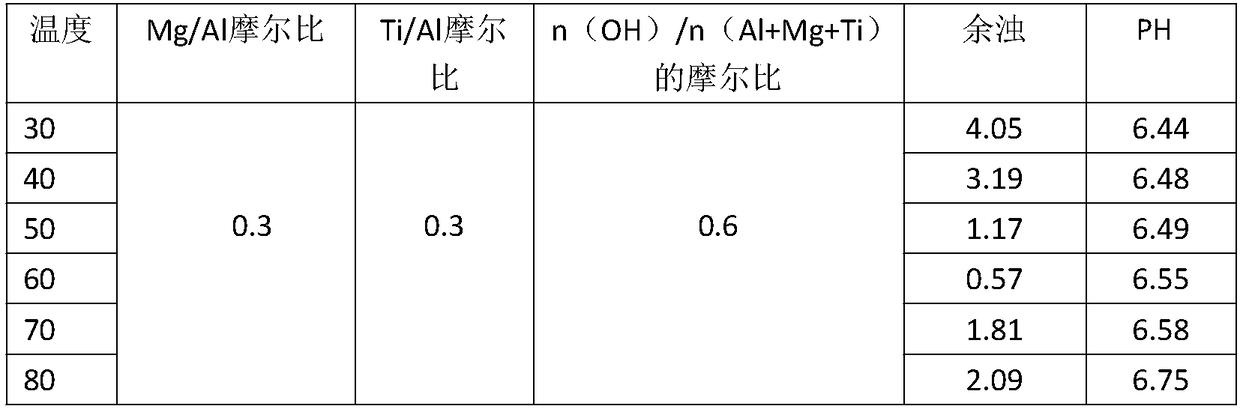

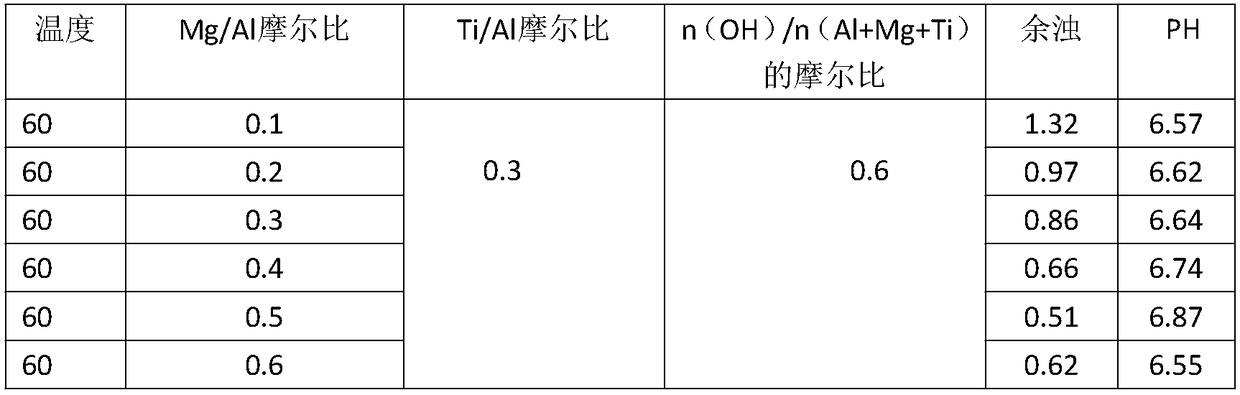

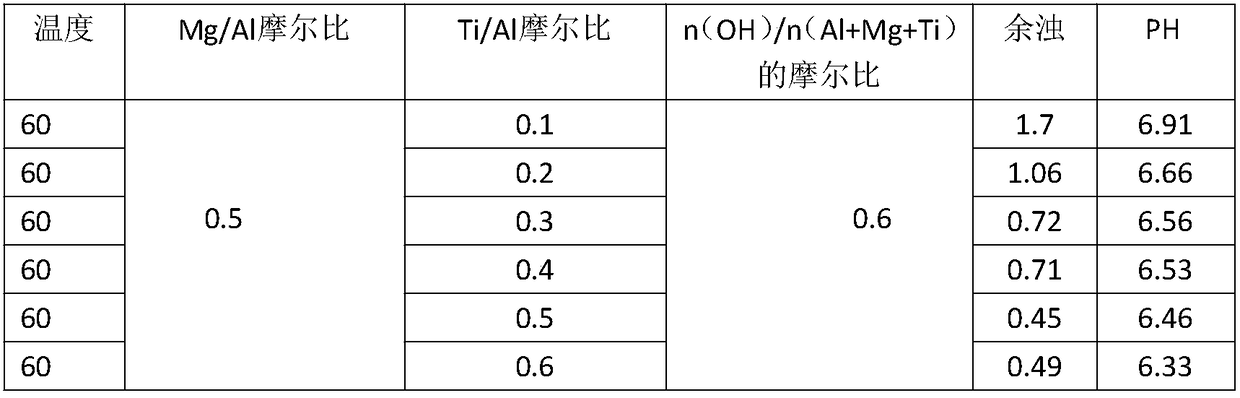

[0027] (2) According to the molar ratio of Mg / Al being 0.1-0.6:1, mix the aluminum chloride and magnesium chloride solution obtained in step (1) to obtain the aluminum-magnesium chloride solution, which is placed in a refrigerator at a temperature of -20 to 5 Place it at ℃ for 20-30min and take it out. According to the Ti / Al molar ratio of 0.1-0.6:1, pipette 0.11-0.66mL of titanium tetrachloride liquid into the aluminum-magnesium chloride...

Embodiment 1

[0035] (1) Take by weighing 2.4163g aluminum chloride hexahydrate white crystals and 0.6099g magnesium chloride hexahydrate white crystals and dissolve them in 60mL of deionized water, fully stir it to dissolve to obtain a colorless and transparent aluminum magnesium chloride solution;

[0036] (2) Place the obtained colorless and transparent aluminum-magnesium chloride solution in a refrigerator at -10°C for 20 minutes and take it out;

[0037] (3) According to the molar ratio of Ti / Al being 0.3, pipette 0.33 mL of titanium tetrachloride liquid into the aluminum-magnesium chloride solution obtained in step (2) to obtain an aluminum-magnesium-titanium chloride solution.

[0038] (4) According to the molar ratio of n(OH) / n(Al+Mg+Ti) is 0.4, add the sodium hydroxide (NaOH) solution that concentration is 2mol / L to the mixed solution in (3) dropwise, add dropwise After completion, stirring was continued in a constant temperature water bath at 60 °C for 2 h.

[0039] (5) Place the...

Embodiment 2

[0045] (1) Weigh 2.4163g aluminum chloride hexahydrate white crystal and 1.0165g magnesium chloride hexahydrate

[0046] Dissolve the white crystals in 60mL of deionized water, stir well to dissolve to obtain a colorless and transparent aluminum-magnesium chloride solution;

[0047] (2) Place the obtained colorless and transparent aluminum-magnesium chloride solution in a refrigerator at -15°C for 25 minutes and take it out;

[0048] (3) According to the molar ratio of Ti / Al being 0.5, pipette 0.55 mL of titanium tetrachloride liquid into the aluminum-magnesium chloride solution obtained in step (2) to obtain an aluminum-magnesium-titanium chloride solution.

[0049] (4) According to the molar ratio of n(OH) / n(Al+Mg+Ti) is 0.6, add the sodium hydroxide (NaOH) solution that concentration is 2mol / L to the mixed solution in (3) dropwise, add dropwise After completion, stirring was continued in a constant temperature water bath at 60 °C for 2 h.

[0050] (5) Place the aluminum-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com