A mold for making column sand molds

A column and mold technology, which is applied in the field of sand mold manufacturing, can solve the problems of sand molds not meeting the requirements of use, sticking in the inner cavity of the mold, and cracking of sand castings, etc., and achieve compact structure, improved fastness, and increased yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

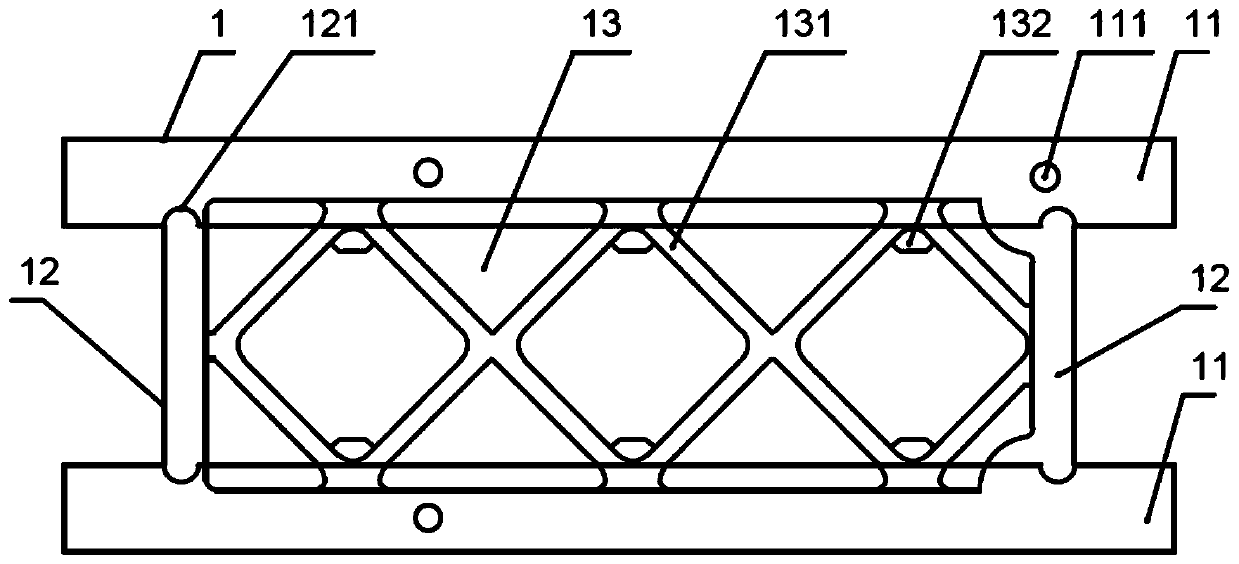

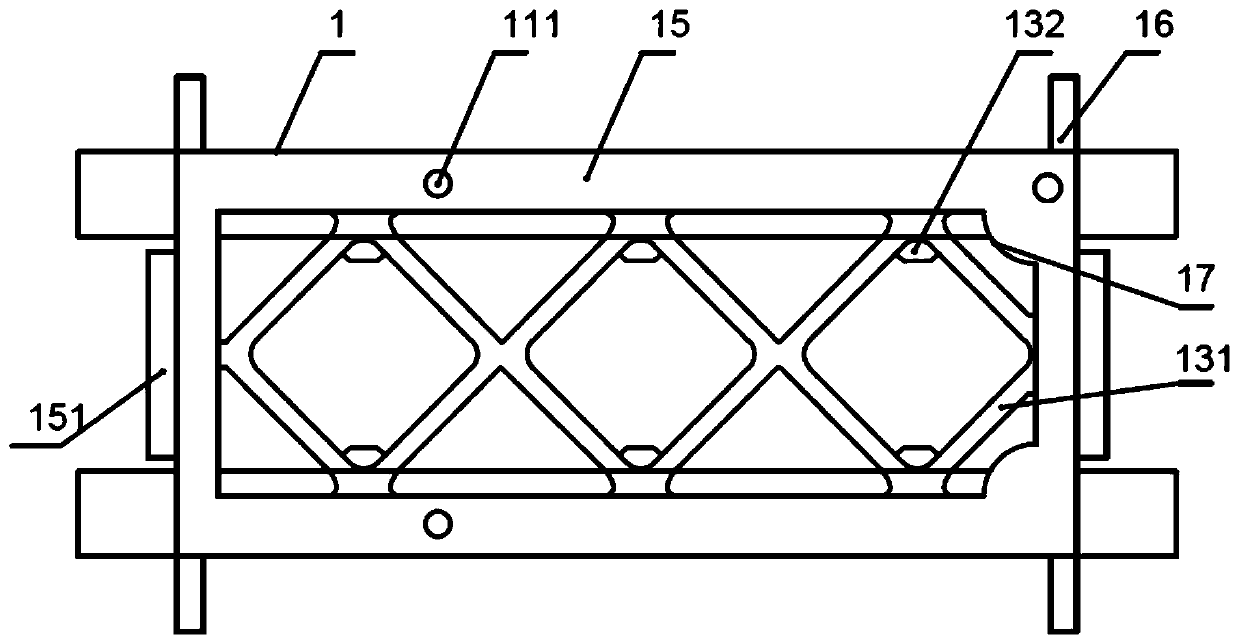

[0048] In order to have a further understanding and recognition of the structural features and the achieved effects of the present invention, the preferred embodiments and accompanying drawings are used for detailed description, as follows:

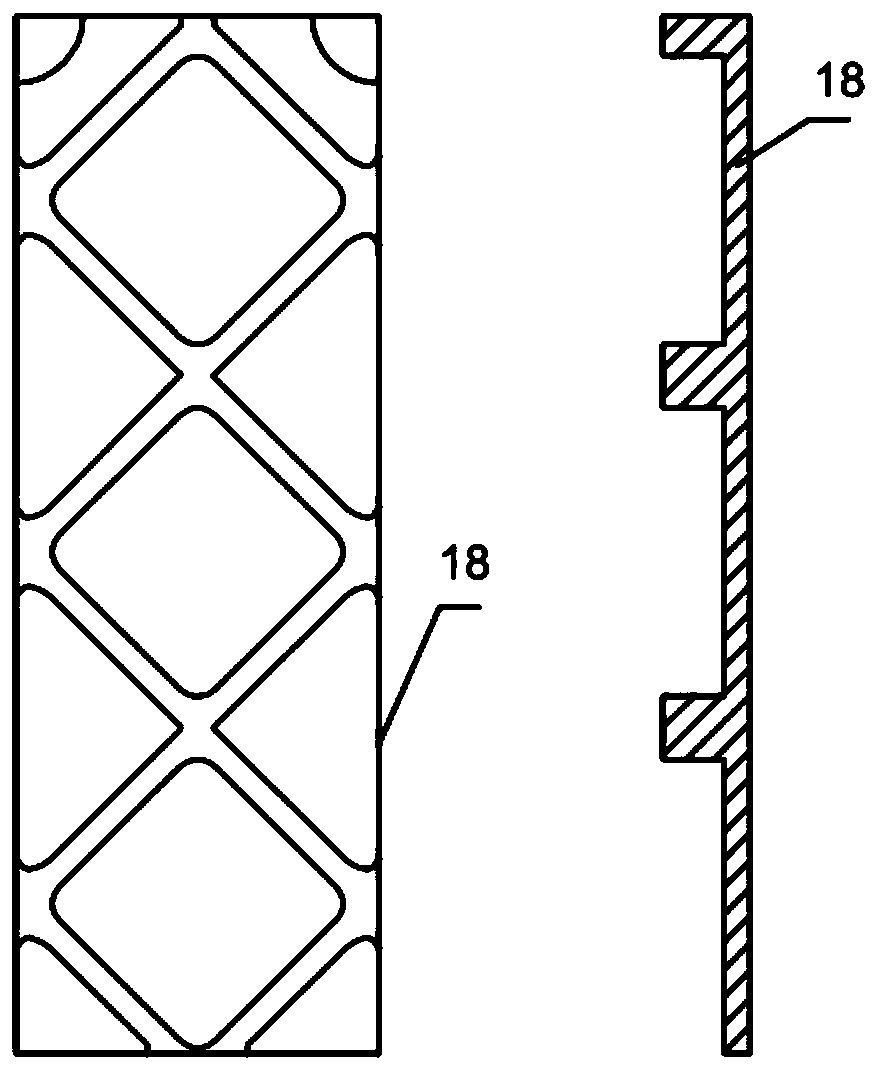

[0049] Such as Figure 11 , 12 As shown, the column 4 includes a column body 41, and the column body 41 includes a connection surface 413. The connection surface 413 extends vertically from the top surface 411 of the column body 41 to the bottom surface 415, and the connection surface 413 separates the column body 41 into a front cavity and a back cavity. body 4141, the connecting surface 413 is provided with a hoisting hole 4132;

[0050] There are multiple connecting surface reinforcing ribs 4131 arranged on the connecting surface 413 in the front cavity, the connecting surface reinforcing ribs 4131 connect the left side wall and the right side wall of the column body 41, and connect the top surface 411 and the bottom surface 415 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com