Fiber/nano manganese dioxide composite material and preparation method and application thereof

A technology of nano-manganese dioxide and composite materials, applied in the field of organic-inorganic composite materials, which can solve the problems of difficult regeneration of adsorbents and the influence of adsorption capacity, and achieve the effects of wide range of reaction conditions, simple use conditions and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method for purifying formaldehyde fiber material, specifically comprising the steps of:

[0032] (1) Pretreated fiber

[0033] Select the TEMPO / NaClO / NaBr system to selectively oxidize the bleached eucalyptus chemical pulp fiber, wash until neutral, and obtain the oxidized fiber;

[0034] (2) Preparation of purified formaldehyde fiber material

[0035] The above-mentioned oxidized fibers were subjected to 0.1mol / L H 2 SO 4 Wash to neutral after soaking for 1h, in 0.05mol / L MnCl 2 After stirring the solution for 1 h, KMnO was added 4 solution, KMnO 4 with MnCl 2 The molar ratio is 1.5:1, the fiber concentration is 1wt%, the stirring rate is 800rpm, the reaction temperature is 50°C, and the reaction time is 20min. Growth of nano-manganese dioxide fibers.

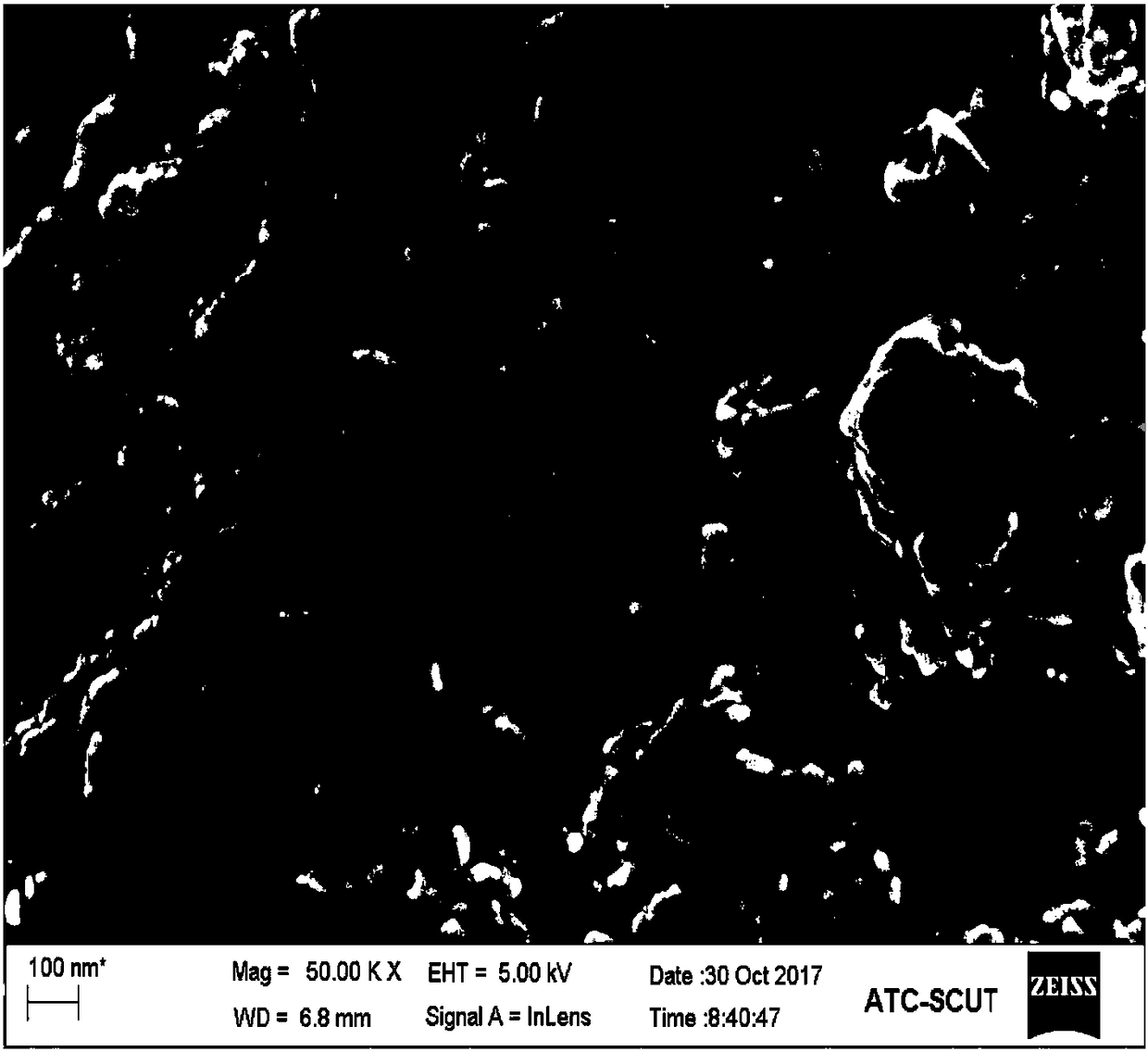

[0036] The scanning electron microscope picture of the obtained fiber / nano-manganese dioxide composite material is as follows: figure 1 shown by figure 1 The nano-manganese dioxide grown in situ ...

Embodiment 2

[0040] A preparation method for purifying formaldehyde fiber material, specifically comprising the steps of:

[0041] (1) Pretreated fiber

[0042] Use laccase / TEMPO / O 2 The system selectively oxidizes the bleached poplar chemical pulp fibers and washes them to neutral to obtain oxidized fibers;

[0043] (2) Preparation of purified formaldehyde fiber material

[0044] The above-mentioned oxidized fibers were soaked in 0.3mol / L HCl for 1h and then washed to neutrality. In 0.1mol / L MnSO 4 After stirring the solution for 3 h, K was added 2 FeO 4 , K 2 FeO 4 with MnSO 4 The molar ratio is 1:1, the fiber concentration is 2wt%, the stirring rate is 1000rpm, the reaction temperature is 30°C, and the reaction time is 30min. After the reaction, wash with deionized water until the washing liquid has no color change, and dry at 80°C for 8h , to obtain in-situ growth nano manganese dioxide fibers.

[0045] The scanning electron microscope picture of the obtained fiber / nano-mangan...

Embodiment 3

[0047] A fiber material for purifying formaldehyde and a preparation method thereof, specifically comprising the steps of:

[0048] (1) Pretreated fiber

[0049] Select TCCA / NHPI / anthraquinone / NaBr system to selectively oxidize tencel fibers, wash to neutral, and obtain oxidized fibers;

[0050] (2) Preparation of purified formaldehyde fiber material

[0051] The above-mentioned oxidized fibers were subjected to 0.05mol / L HNO 3 After soaking for 24 hours, wash to neutral, at 0.005mol / L (CH 3 COO) 2 After stirring the Mn solution for 5 h, adding H 2 o 2 , H 2 o 2 with (CH 3 COO) 2 The molar ratio of Mn is 3:1, the fiber concentration is 5wt%, the stirring rate is 200rpm, the reaction temperature is 10°C, and the reaction time is 240min. Fibers grown from nano-manganese dioxide.

[0052] After the reaction, a fiber / nano manganese dioxide composite material is obtained, and the nano manganese dioxide particles are spherical, uniformly and densely distributed on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com