Bus duct

A technology of bus duct and side plate, applied in the field of bus duct, can solve the problems of high cost, complicated installation, corrosion, etc., and achieve the effect of simple manufacturing process, convenient installation and transportation, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

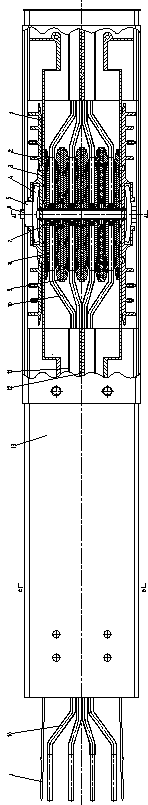

[0018] As shown in the figure, a bus duct includes a housing composed of a side plate 12 and a cover plate 13, and a phase line conductor 10 placed in the inner cavity of the housing; the bus duct side plate 12 and the cover plate 13 of the embodiment of the present invention are One-piece pultruded one-piece side cover plate, the left and right two-part one-piece side cover plate can use profiles of different cross-sections to cooperate with each other to form a shell, and profiles of the same cross-section can also be used to cooperate with each other to form a shell; the shoulder of the side plate Auxiliary support plates 11 can be provided to improve the support strength of the side plates and at the same time improve the protection level to prevent the accumulation of dust and rain; the sections of the bus duct are connected through connectors;

[0019] The connector includes a number of insulating partitions 3, conductor connecting pieces 8 and heat sinks 9 distributed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com