Carbon-coated NiPx nanometer composite electrode material with monodisperse structure characteristic, and preparation method thereof

A carbon composite material and nanocomposite technology, applied in the direction of nanotechnology, nanotechnology, structural parts, etc. for materials and surface science, can solve the problems of poor cycle stability and low specific capacity, and achieve easy operation and high specific capacity , Excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

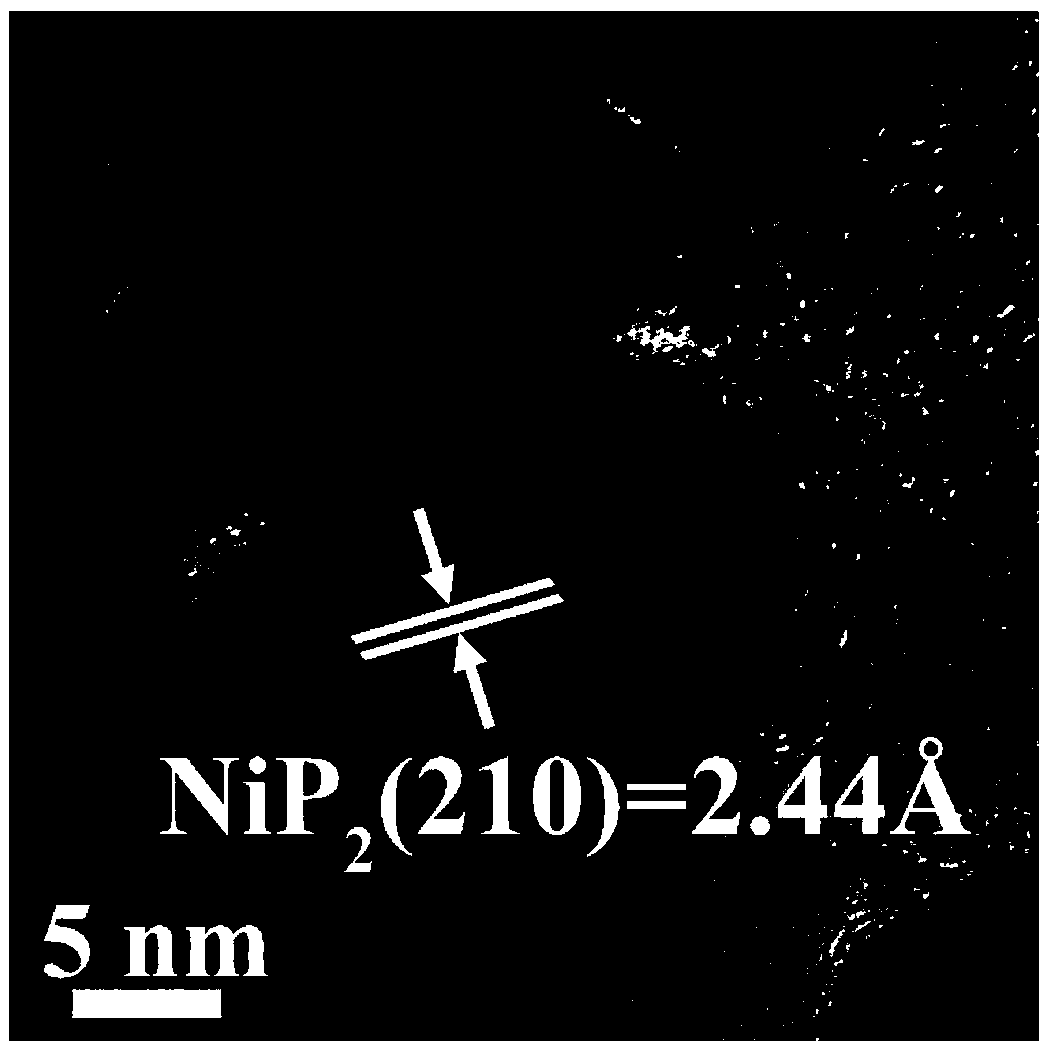

[0057] Carbon-coated NiP with monodisperse structure characteristics 2 Preparation of nanocomposite electrode materials:

[0058] Weigh 500 mg of multi-walled carbon nanotubes (XF NANO, INC, XFM19) and add them to 50 ml of concentrated nitric acid. Wall carbon nanotubes are centrifuged and cleaned until the pH of the supernatant is about 7. There are a large number of functional group molecules on the surface of the acidified carbon nanotubes, which can improve the surface activity of the material. Get the above-mentioned multi-walled carbon nanotube carbon material 500mg after acidification, and 10mmol Ni(NO 3 ) 2After mixing and grinding, the mixture was dissolved in 350 mL of N-methylpyrrolidone, and heated to reflux while stirring. The reflux temperature was 180° C. for 1 h. The obtained product was centrifuged, dried, and then calcined in an air atmosphere at a temperature of 350° C. for 1 h to obtain a nickel monoxide / carbon composite material. Take 100 mg of the ni...

Embodiment 2

[0062] Preparation of carbon-coated NiP nanocomposite electrode materials with monodisperse structural features:

[0063] Weigh 500mg of multi-walled carbon nanotubes and add them to 50ml of concentrated nitric acid. After ultrasonic treatment for 5 minutes, condense and reflux in an oil bath at 150°C, and centrifugally clean the obtained acidified multi-walled carbon nanotubes to the pH of the supernatant. The value is around 7. There are a large number of functional group molecules on the surface of the acidified carbon nanotubes, which can improve the surface activity of the material. Get the above-mentioned multi-walled carbon nanotube carbon material 500mg after acidification, and 10mmol Ni(NO 3 ) 2 After mixing and grinding, the mixture was dissolved in 350 mL of N-methylpyrrolidone, and heated to reflux while stirring. The reflux temperature was 180° C. for 1 h. The obtained product was centrifuged, dried, and then calcined in an air atmosphere at a temperature of 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com