An electronic control development and test system for simulating fuel cells

A fuel cell and test system technology, applied in electrical testing/monitoring, measuring electricity, measuring devices, etc., to achieve the effect of safely developing battery systems and improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

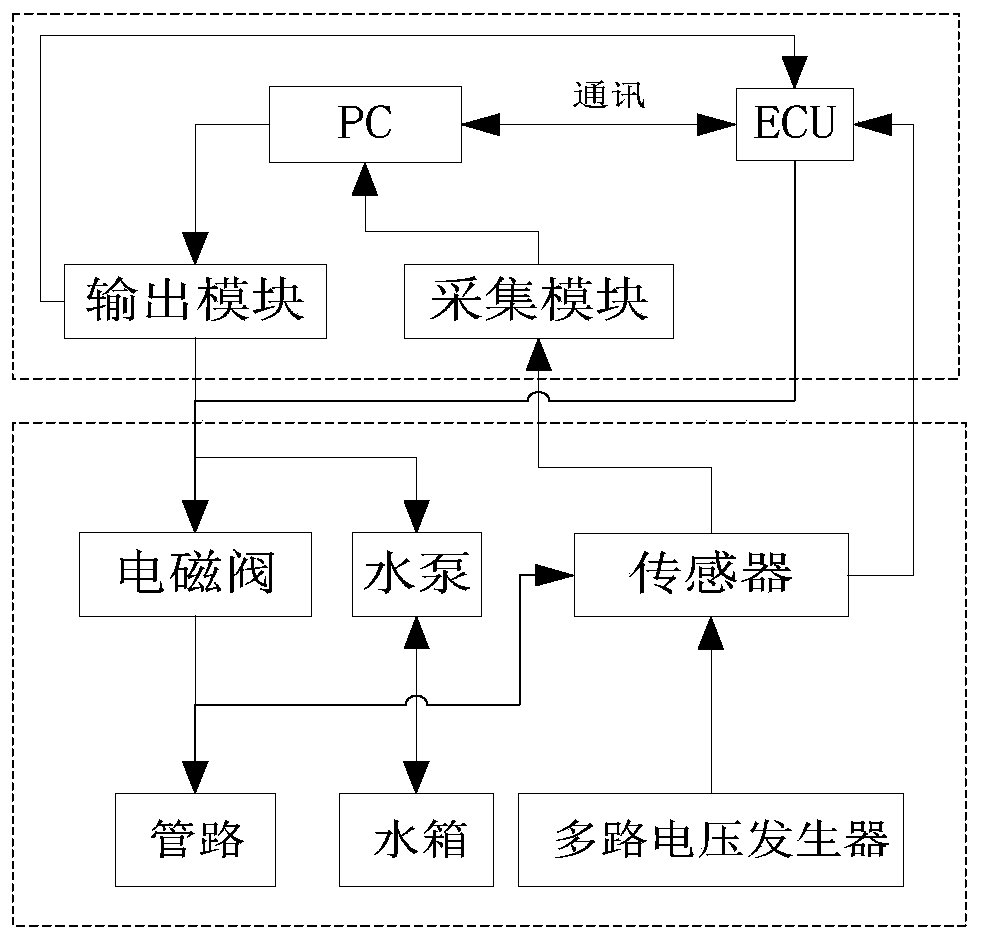

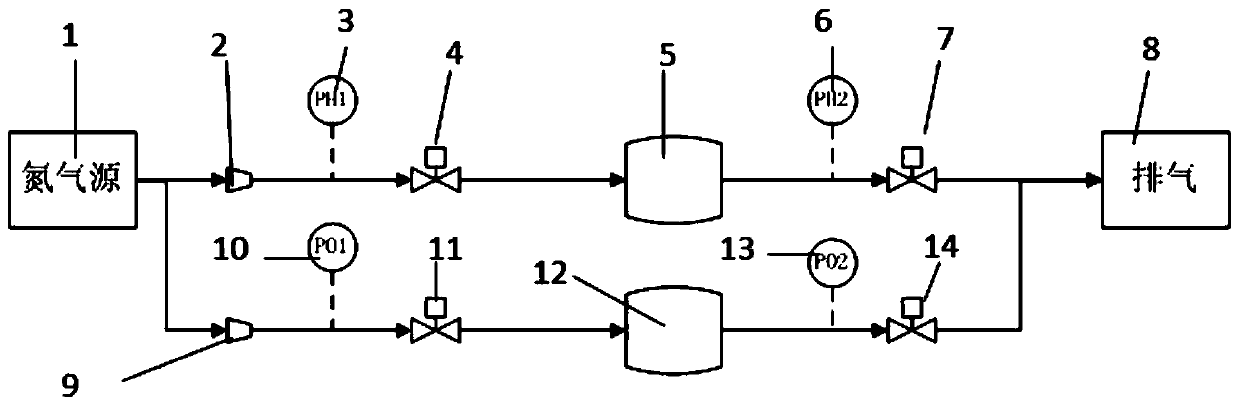

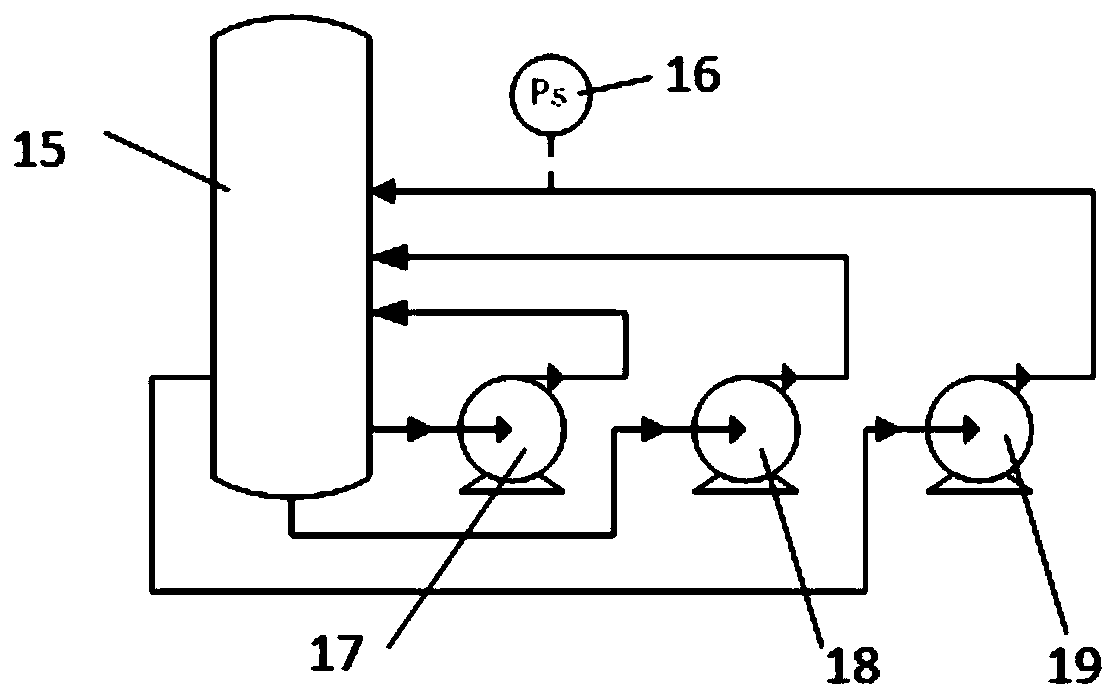

[0032] The mechanical pipeline of the test bench is completely the actual working pipeline of a fuel cell system. The difference is that a buffer tank is used to simulate the cavity volume of the battery. In terms of gas source, the air source or nitrogen source is uniformly used to simulate hydrogen, oxygen, and nitrogen sources after decompression and stabilization. The three pressure regulator valves can adjust the air source to simulate the real air source pressure. After the ECU is connected to the pipeline pressure control solenoid valve, the test pressure balance program can be developed. After debugging, there will be deviations when transplanted to the real system, but the deviations will not be very large, and a slight adjustment is enough. Install a multi-channel voltage generator to simulate the output voltage of the battery. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com