Laser bijective sensor for evaluating return-washing effect of hollow fiber membranes

A laser emitter, fiber membrane technology, applied in instruments, scientific instruments, material analysis by optical means, etc., can solve the problems of insufficient cleaning effect, difficulty in evaluation and analysis, etc., achieving small size, low cost, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

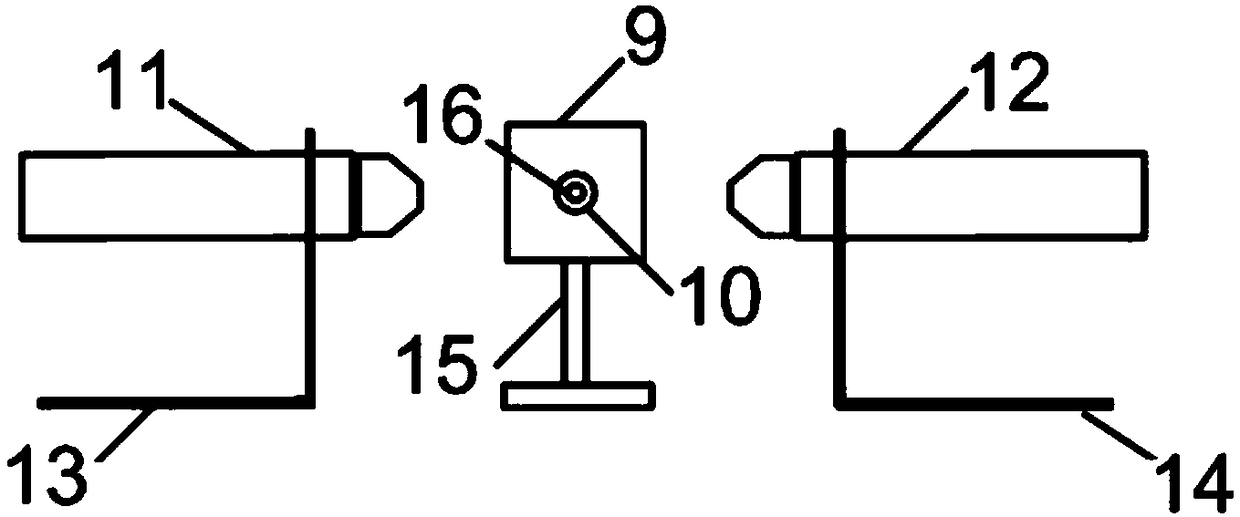

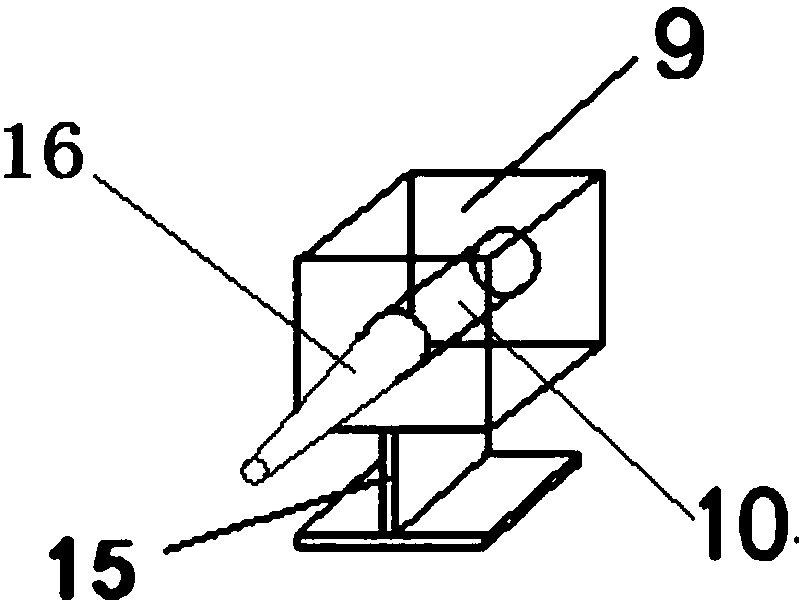

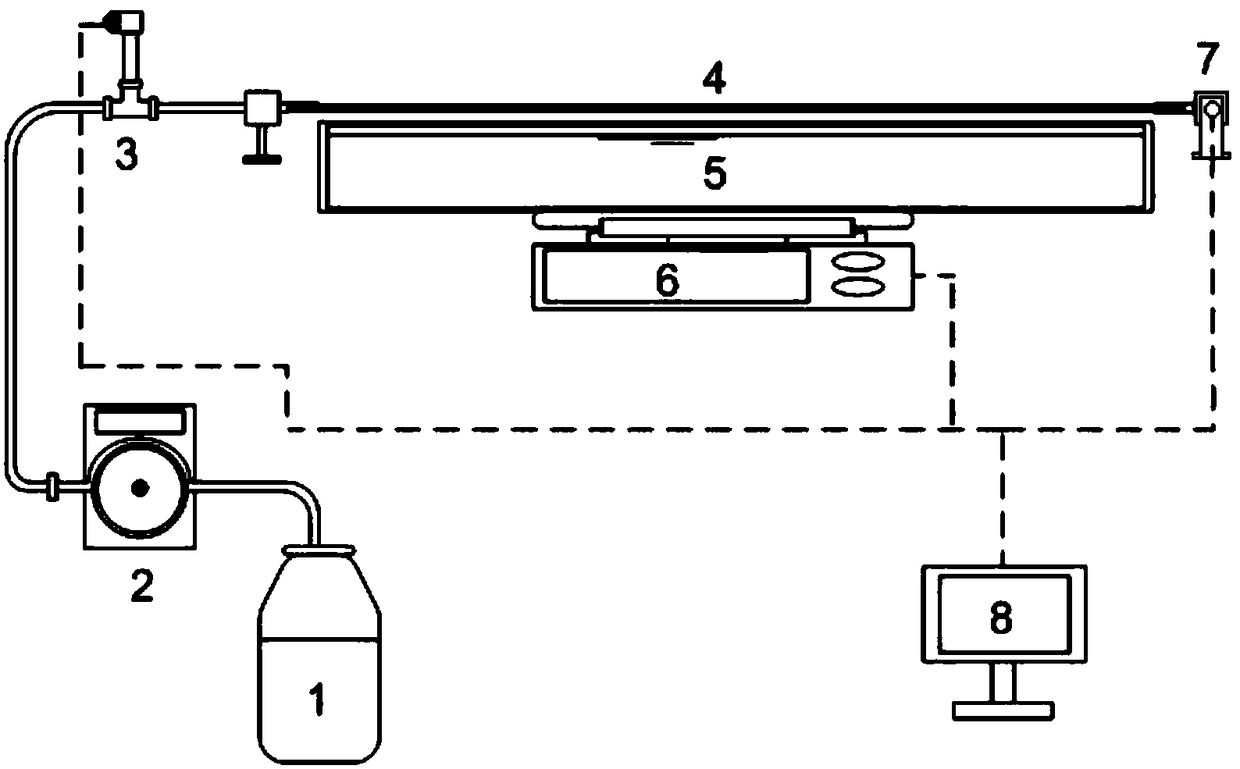

[0020] A laser dual-shot sensor for evaluating the backwashing effect of hollow fiber membranes (see figure 1 with figure 2 ), comprising a laser transmitter 11 and a laser receiver 12, a detection cube 9 of a transparent material is arranged between the laser transmitter 11 and the laser receiver 12, the detection cube runs through and is provided with a circular channel 10, and a port of the circular channel Connect with connecting pipe 16.

[0021] The sensor also includes a first bracket 13, a second bracket 14 and a third bracket 15, the first bracket is connected with the laser transmitter, the second bracket is connected with the laser receiver, and the third bracket is connected with the detection cube.

[0022] The cube is preferably a cube.

[0023] The diameter of the circular channel is selected from any value from 0.05 to 0.2 cm, such as 0.05, 0.06, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com