Method for improving efficiency of ferulic acid and p-coumaric acid separation

A technology for p-coumaric acid and separation efficiency, applied in the field of effective utilization of biomass resources, can solve the problems of large amount of solvent, restrictions on the wide application of ferulic acid, and high cost, and achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

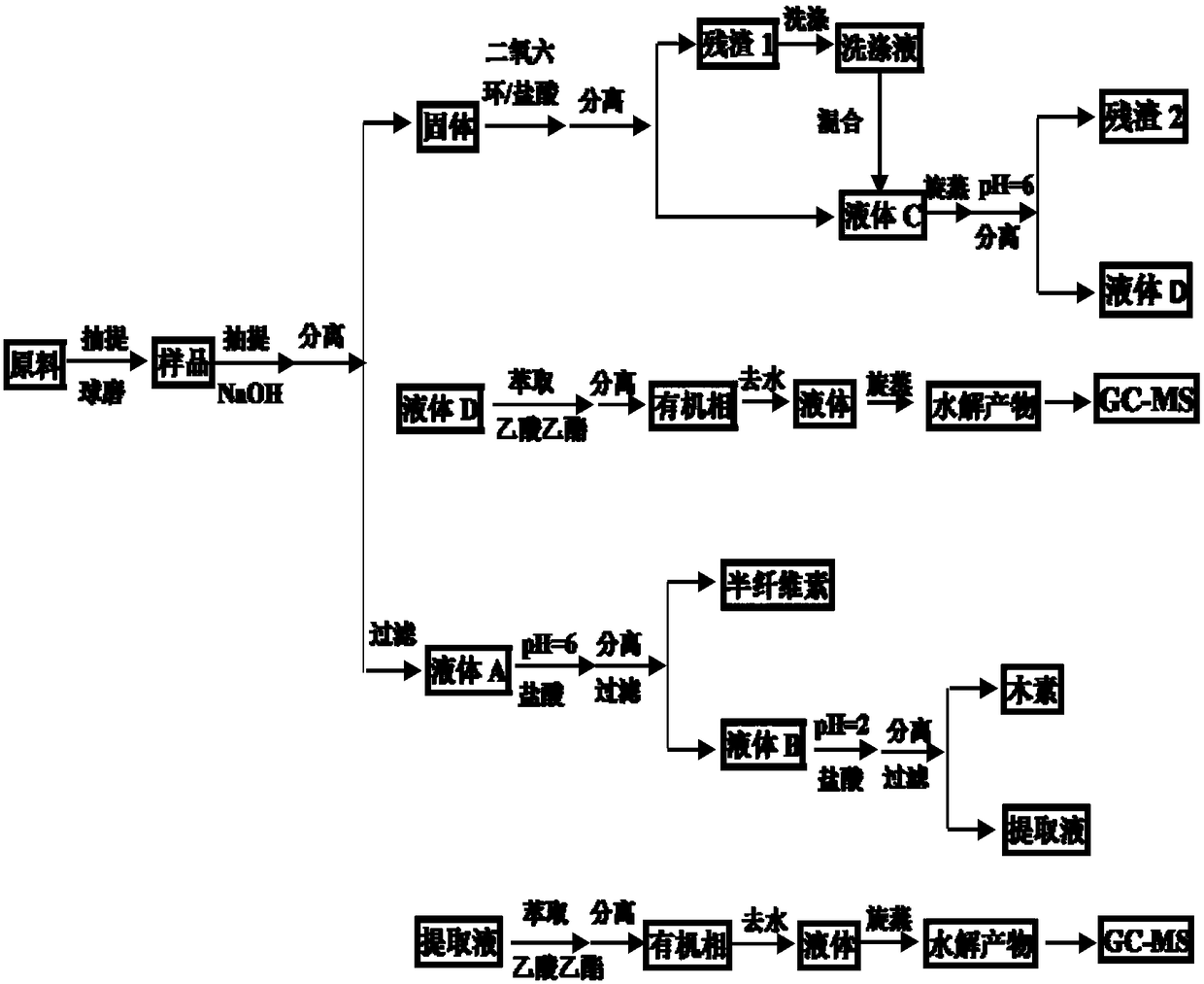

[0023] Such as figure 1 Shown, a kind of method that improves ferulic acid and p-coumaric acid separation efficiency, operates as follows:

[0024] 1. After hydrolyzing ball-milled bagasse with NaOH solution, separate solid and liquid A; adjust the pH of liquid A to 5, add ethanol with a volume concentration of 95% to precipitate and separate 12% hemicellulose, obtain liquid B, and remove ethanol by rotary evaporation.

[0025] 2. Adjust the pH of liquid B to 1, and centrifuge to separate 10% lignin to obtain an extract;

[0026] 3. Extract the extract with ethyl acetate, separate the organic phase, remove the water from the organic phase, and spin evaporate to obtain ferulic acid and p-coumaric acid.

[0027] 4. Treat the solid with 100ml of dioxane / hydrochloric acid mixed solution, reflux reaction in an oil bath at 80°C for 3 hours, and separate after cooling to obtain residue 1 and liquid C; wherein, the volume ratio of dioxane / hydrochloric acid is 9:1, HCl concentration ...

Embodiment 2

[0032] Such as figure 1 Shown, a kind of method that improves ferulic acid and p-coumaric acid separation efficiency, operates as follows:

[0033] 1. After hydrolyzing ball-milled bagasse with NaOH solution, separate solid and liquid A; adjust the pH of liquid A to 6, add ethanol with a volume concentration of 95% to precipitate and separate 14% hemicellulose, obtain liquid B, and remove ethanol by rotary evaporation .

[0034] 2. Adjust the pH of liquid B to 1-2, and centrifuge to separate 8% lignin to obtain an extract;

[0035] 3. Extract the extract with ethyl acetate, separate the organic phase, remove the water from the organic phase, and spin evaporate to obtain ferulic acid and p-coumaric acid.

[0036] 4. Treat the solid with 100ml of dioxane / hydrochloric acid mixed solution, reflux reaction in an oil bath at 80°C for 3 hours, and separate after cooling to obtain residue 1 and liquid C; wherein, the volume ratio of dioxane / hydrochloric acid is 9:1, HCl concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com