Length measuring device and length measuring oil cylinder

A length measuring device and length measuring technology, applied in measuring devices, mechanical measuring devices, electrical devices, etc., can solve the problems of occupying the internal space of the equipment used, large measuring distance, high cost, etc., and achieve small space occupation, small volume, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

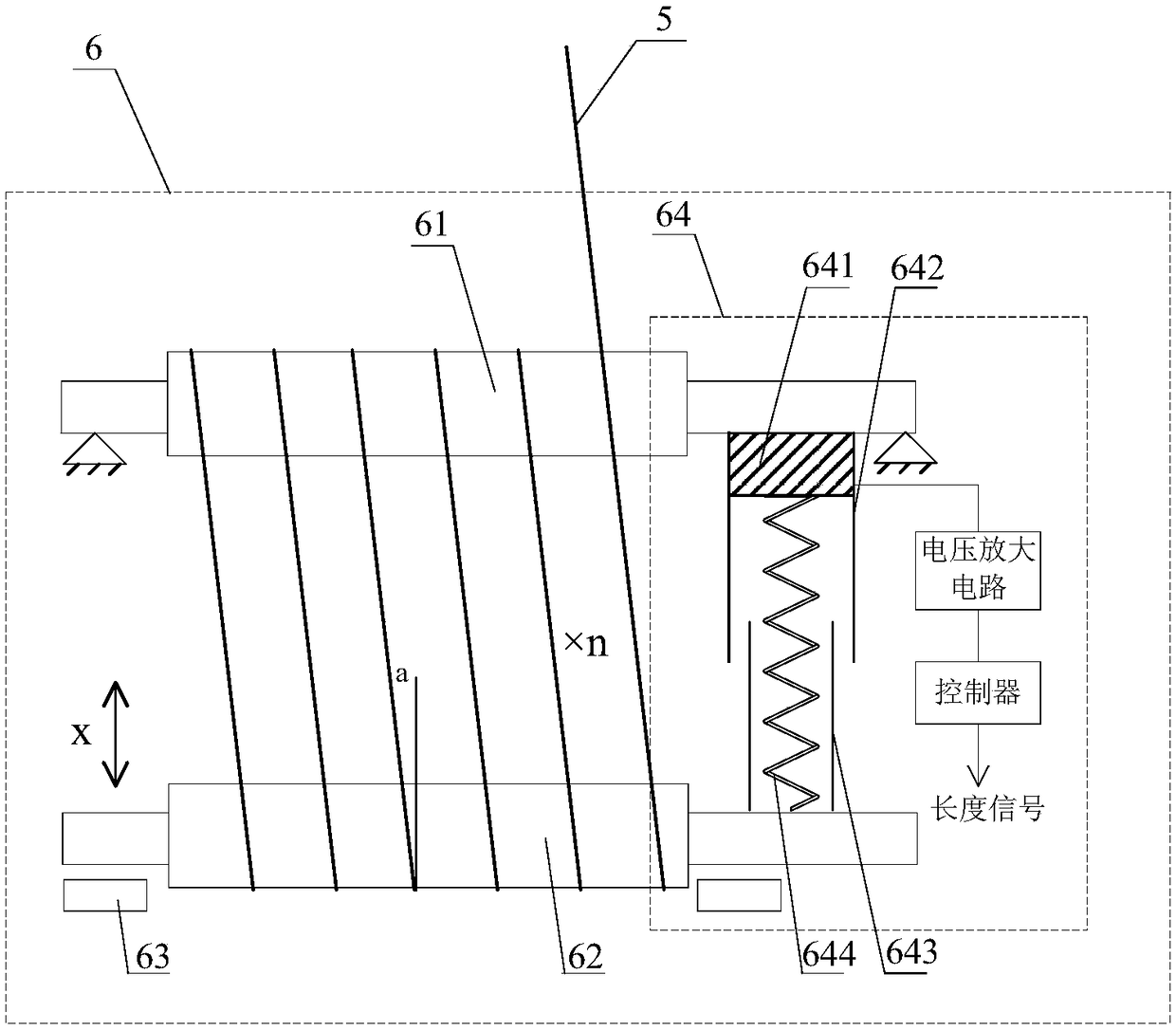

Embodiment 1

[0033] like figure 1 Shown, a kind of length measuring device comprises fixed pulley block 61, movable pulley block 62, positioning device 63, length measuring rope 5, piezoelectric material 641, spring 644, voltage amplifying circuit, controller; The pulley block 62 and the fixed pulley block 61 form a pulley block structure, the fixed pulley block is fixed, the movable pulley block moves back and forth along the measurement direction, and a positioning device 63 is set on the movable pulley block side (relative to the direction of the fixed pulley block) to limit the displacement of the movable pulley block. Sleeve I 642 is fixed on the fixed pulley block, and sleeve II 643 is fixed on the movable pulley block. Sleeve II 643 slides within sleeve I 642 . A piezoelectric material 641 is placed inside the sleeve 1. The spring 644 is arranged in the sleeve I and the sleeve II, one end is connected to the piezoelectric material 641 , and the other end is connected to the movabl...

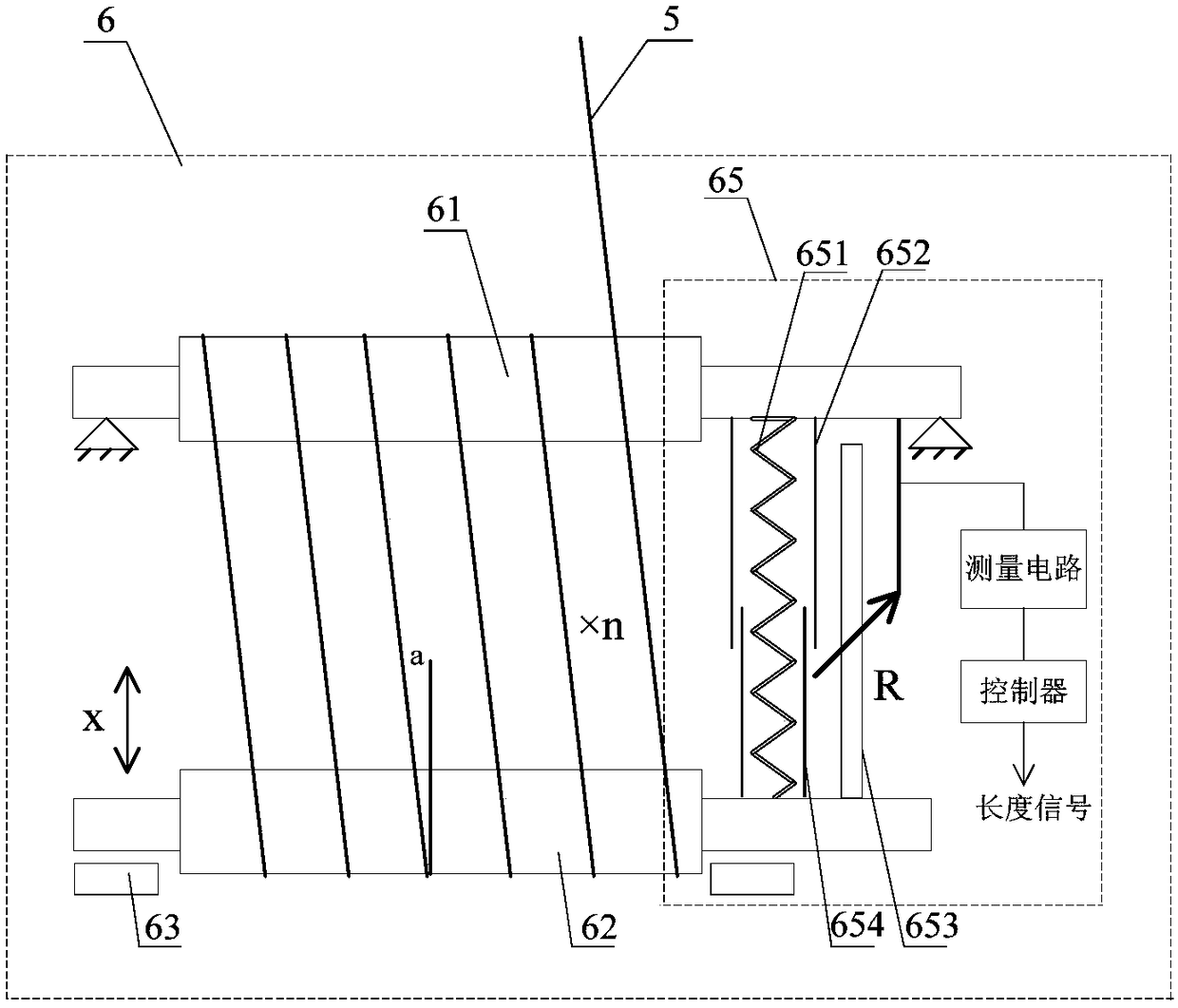

Embodiment 2

[0048] like figure 2 As shown, a length measuring device includes a fixed pulley block 61, a movable pulley block 62, a positioning device 63, a length measuring rope 5, a variable resistor 653, a spring 651, a voltage measurement circuit, and a controller; the length measuring rope is wound around the movable pulley block in turn 1. Form the pulley block structure on the fixed pulley block, the fixed pulley block is fixed, and the movable pulley block moves back and forth along the measuring direction, and the positioning device 63 is set to limit the displacement of the movable pulley block on the movable pulley block side (relative to the direction of the fixed pulley block). Sleeve I is fixed on the fixed pulley block, and sleeve II is fixed on the movable pulley block. Sleeve II 654 slides within sleeve I 652 . The spring is arranged in the sleeve I and the sleeve II, one end is connected with the fixed pulley block, and the other end is connected with the movable pulle...

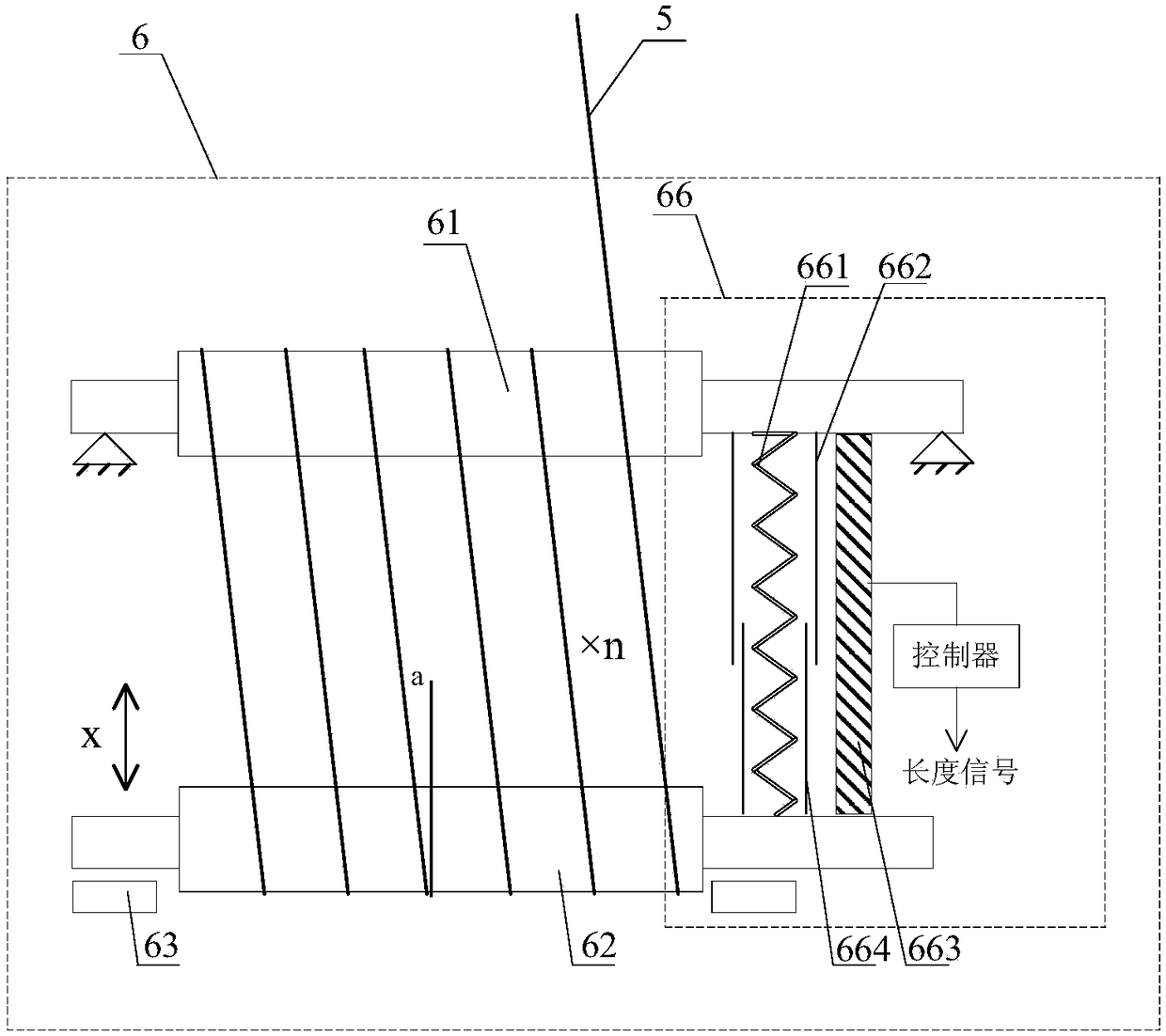

Embodiment 3

[0061] like image 3 As shown, a length measuring device includes a fixed pulley block 61, a movable pulley block 62, a positioning device 63, a length measuring rope 5, a spring 661, a length measuring displacement sensor 663, and a controller;

[0062] The length-measuring rope is wound on the movable pulley block 62 and the fixed pulley block 61 in sequence to form a pulley block structure. The fixed pulley block is fixed, and the movable pulley block moves back and forth along the measuring direction. A positioning device 63 is set on the side of the movable pulley block (relative to the direction of the fixed pulley block) to limit Displacement of movable pulley block. Sleeve I 662 is fixed on the fixed pulley block, and sleeve II 664 is fixed on the movable pulley block. Sleeve II slides inside sleeve I. Spring 661 is arranged in sleeve I 662 , sleeve II 664 . The length-measuring displacement sensor 663 is connected to the movable pulley block, the fixed pulley block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com