An aluminum alloy section bar provided with a double-shaft linear guide rail and specially used for a setting machine

A technology of aluminum alloy profiles and linear guide rails, which is applied in the field of aluminum alloy profiles, can solve the problems of heavy weight of the grab plate, and achieve the effects of reducing weight, increasing effective loading, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

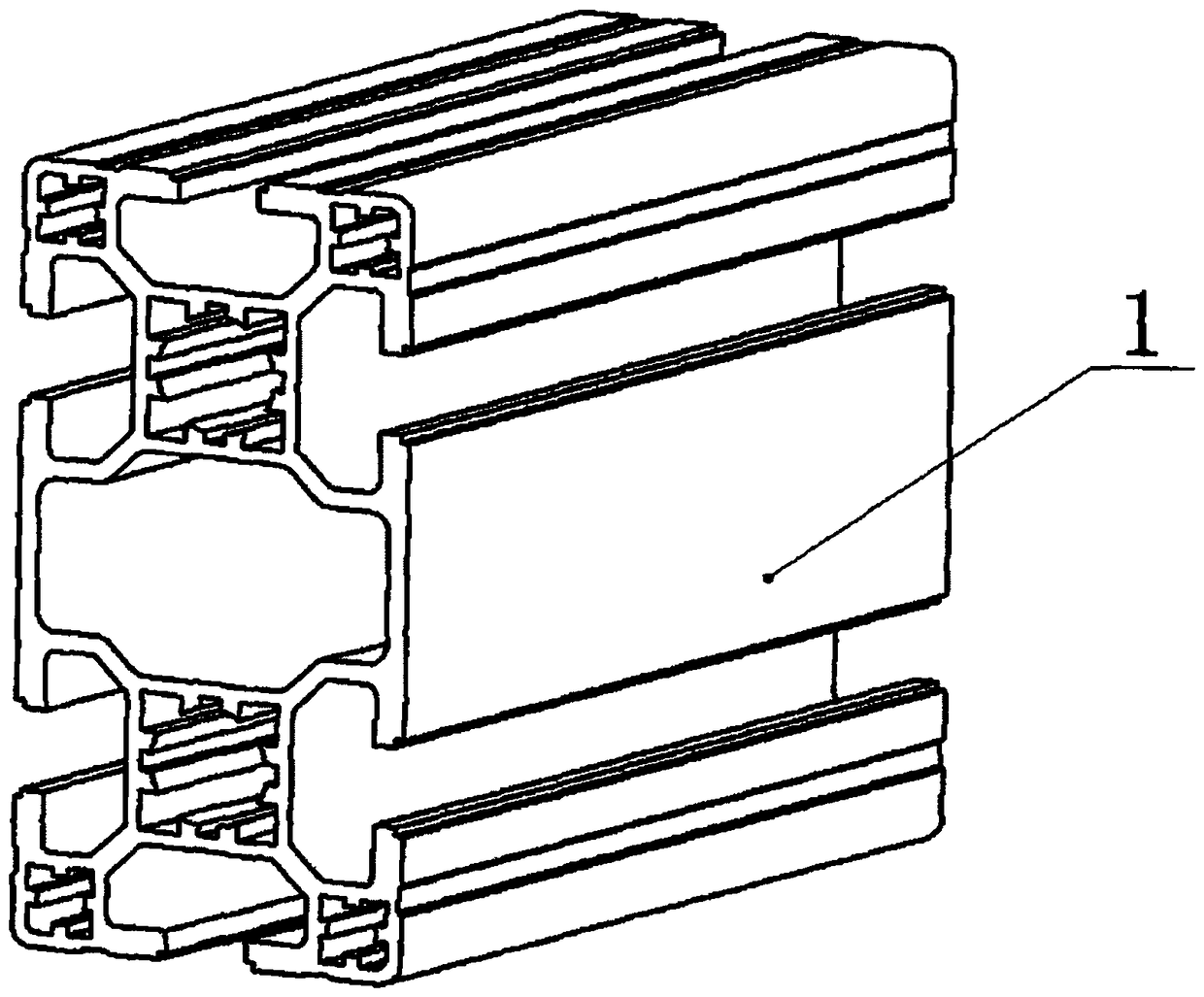

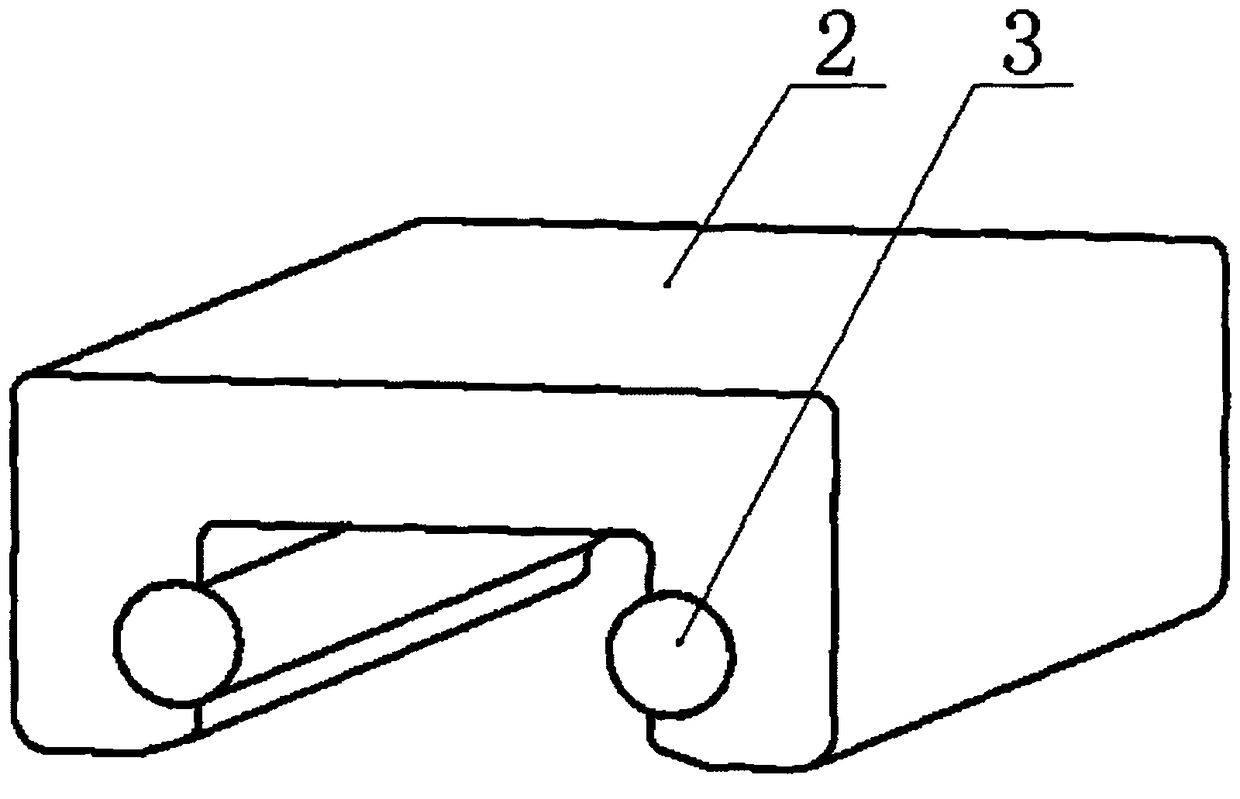

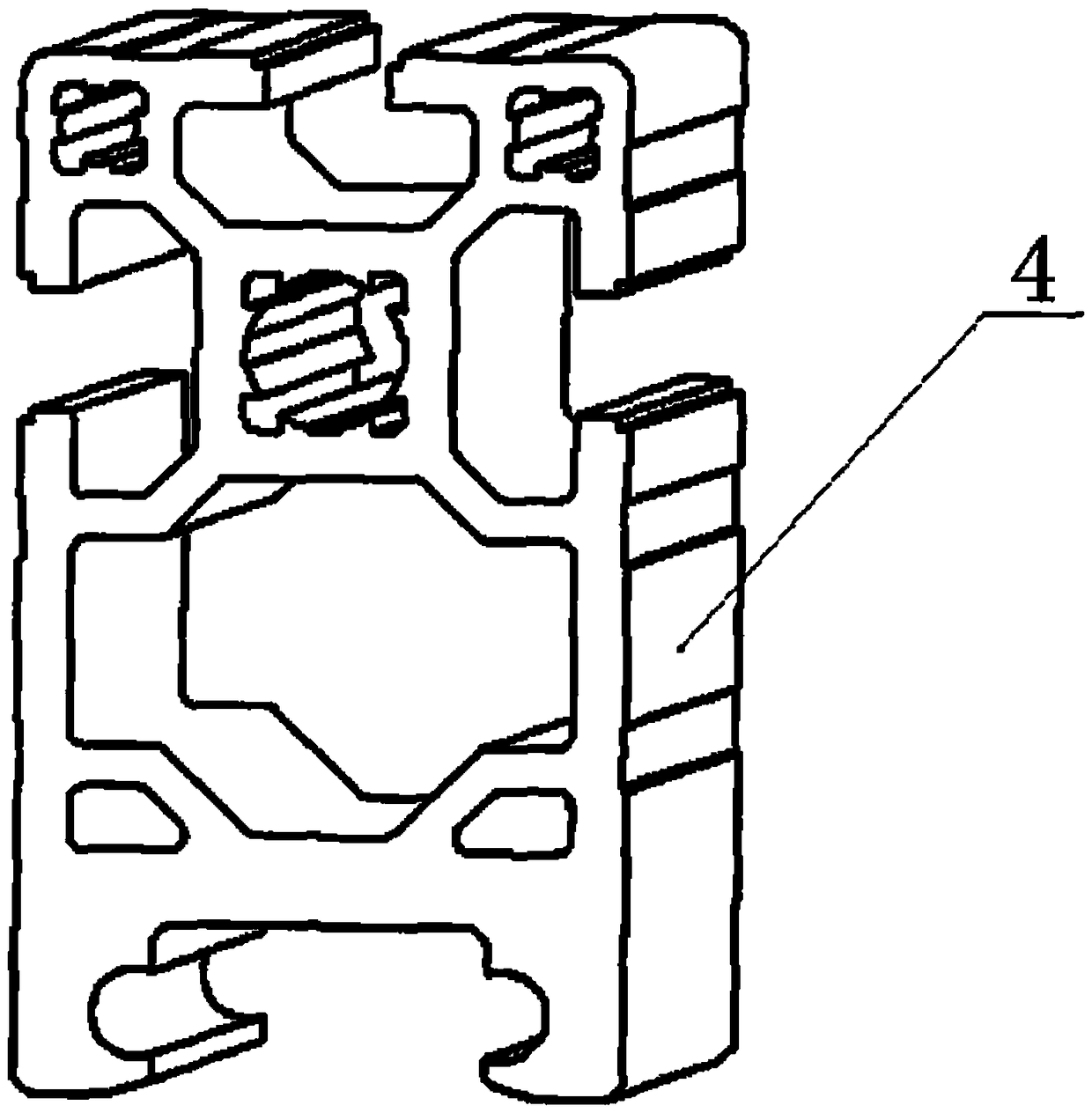

[0013] Combine the aluminum alloy profile (1) and the biaxial linear guide rail (2) together as required, and extrude it into an aluminum alloy profile body (4) with biaxial linear guide rail specially for the billet machine at one time, and then install the guide rail shaft ( 3), the guide rail shaft (3) is made of bearing steel, and is embedded in the predetermined groove of the aluminum alloy profile body (4) with a biaxial linear guide rail, and most of the original installation grooves of the aluminum alloy profile (1) are retained. The finished product (6) of aluminum alloy profiles with double-axis linear guide rails for billet stacking machines can not only retain the original bearing capacity of aluminum alloy profiles (1), but also have the ability of the double-axis linear guide rails (2) to carry linear motion and resist torsion.

Embodiment 2

[0015] The biaxial linear guide rail (2) can be combined in any position such as the bottom, side, and top of the aluminum alloy profile (1) according to design requirements, and extruded into an aluminum alloy profile body (4) with a biaxial linear guide rail.

Embodiment 3

[0017] Two or more biaxial linear guide rails (2) can be combined in the same aluminum alloy profile (1) according to design requirements, and extruded into an aluminum alloy profile body with multiple biaxial linear guide rails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com