Heat insulation and corrosion resistant aluminum alloy door window surface treatment method

A technology for aluminum alloy doors and windows, surface treatment, applied in door/window applications, windows/doors, fire doors, etc., can solve the problems of poor performance in the direction of heat insulation and corrosion resistance of aluminum alloy doors and windows, so as to avoid damage and guarantee The effect of completeness and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for surface treatment of heat-insulating and corrosion-resistant aluminum alloy doors and windows, comprising the steps of:

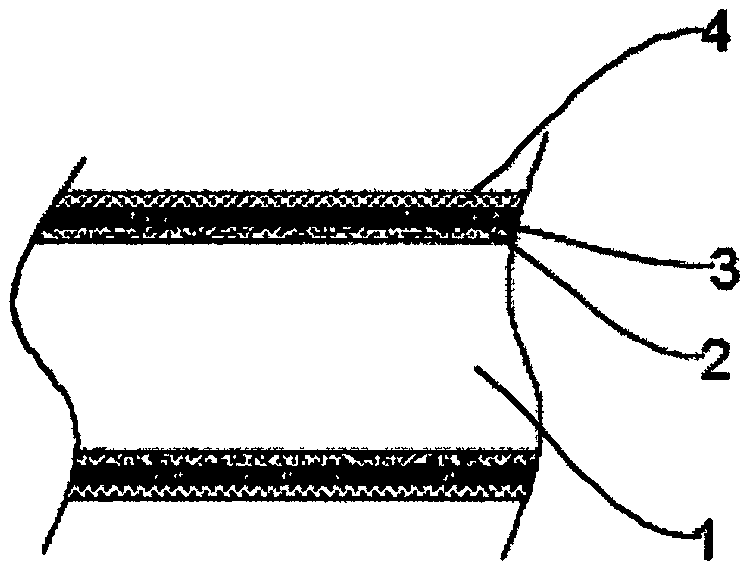

[0030] 1) Cut the two ends of the aluminum alloy profile 1 that needs to be framed to 45°, and set a dovetail at both ends of the aluminum alloy profile 1;

[0031] 2) Connect four aluminum alloy profiles 1 end-to-end, and use dovetail joints to connect the four pieces by extrusion to form a frame;

[0032] 3) polishing the outer surface of the frame;

[0033] 4) Mix epoxy resin glue, silicon dioxide, calcium silicate and coupling agent in the following parts by weight to obtain a low-melting adhesive layer paste: 30 parts of epoxy resin, 12 parts of silicon dioxide, 10 parts of silicon carbide Parts, 10 parts of coupling agent;

[0034] 5) Apply the adhesive layer paste evenly on the outer surface of the frame, and air-dry it at room temperature, and then use a laser beam at 500°C to anneal the adhesive layer paste to form an adhesive...

Embodiment 2

[0040] A method for surface treatment of heat-insulating and corrosion-resistant aluminum alloy doors and windows, comprising the steps of:

[0041] 1) Cut the two ends of the aluminum alloy profile 1 that needs to be framed to 45°, and set a dovetail at both ends of the aluminum alloy profile 1;

[0042] 2) Connect four aluminum alloy profiles 1 end-to-end, and use dovetail joints to connect the four pieces by extrusion to form a frame;

[0043] 3) polishing the outer surface of the frame;

[0044] 4) Mix epoxy resin glue, silicon dioxide, calcium silicate and coupling agent in the following parts by weight to obtain a low-melting adhesive layer paste: 32 parts of epoxy resin, 16 parts of silicon dioxide, 10 parts of silicon carbide Parts, 11 parts of coupling agent;

[0045] 5) Apply the adhesive layer paste evenly on the outer surface of the frame, and air-dry it at room temperature, and then use a laser beam at 800°C to anneal the adhesive layer paste to form an adhesive...

Embodiment 3

[0051] A method for surface treatment of heat-insulating and corrosion-resistant aluminum alloy doors and windows, comprising the steps of:

[0052] 1) Cut the two ends of the aluminum alloy profile 1 that needs to be framed to 45°, and set a dovetail at both ends of the aluminum alloy profile 1;

[0053] 2) Connect four aluminum alloy profiles 1 end-to-end, and use dovetail joints to connect the four pieces by extrusion to form a frame;

[0054] 3) polishing the outer surface of the frame;

[0055] 4) Mix epoxy resin glue, silicon dioxide, calcium silicate and coupling agent in the following parts by weight to obtain a low-melting adhesive layer paste: 33 parts of epoxy resin, 15 parts of silicon dioxide, and 11 parts of silicon carbide Parts, 10 parts of coupling agent;

[0056] 5) Apply the adhesive layer paste evenly on the outer surface of the frame, and air-dry it at room temperature, and then use a laser beam at 600°C to anneal the adhesive layer paste to form an adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com