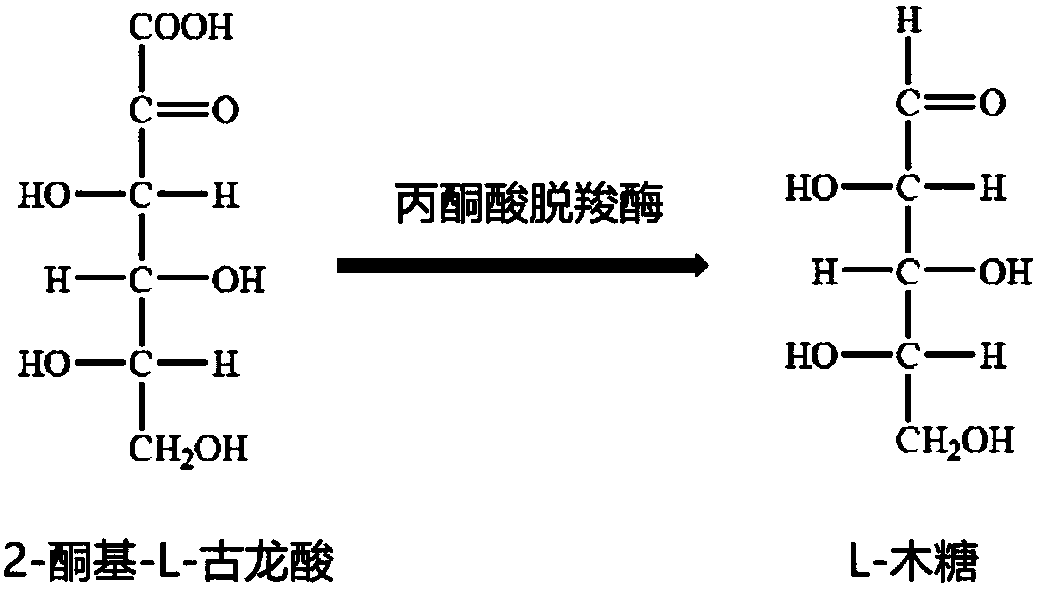

Enzymatic method for preparing L-xylose

An enzymatic and xylose technology, applied in the field of enzymatic preparation of L-xylose, can solve the problems affecting the extraction process and product quality, unsuitable for L-xylose raw materials, low post-processing efficiency, etc., to achieve low pollution and easy operation Simple and easy to control, the effect of a single raw material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of pyruvate decarboxylase

[0023] Primers were designed according to the pyruvate decarboxylase gene sequence of Saccharomyces cerevisiae in Genebank, as follows:

[0024] Upstream primer: CATGCCATGGATTCAATTACTTTGGGTAAATATTTGTTCG

[0025] Downstream primer: CCGCTCGAGTTGCTTAGCGTTGGTAGCAGCAGTC

[0026] After the PCR product of pyruvate decarboxylase was inserted into the plasmid pET-22b, the recombinant expression plasmid pET-22b-pdc was constructed.

[0027] Take 0.01g of the recombinant expression plasmid pET-22b-pdc to transform Escherichia coli BL21(DE3) competent cells, culture in 600μL LB medium for 1h, take 100μL of the bacterial liquid and spread it on a solid LB plate containing ampicillin, at 37℃ Cultivate for 10 hours to obtain genetically engineered bacteria capable of highly expressing pyruvate decarboxylase.

[0028] The constructed engineered bacteria were inoculated in TB medium containing ampicillin, and cultured at 37°C until the bact...

Embodiment 2

[0032] Substantially the same as Example 1, the difference is that the buffer is an MES buffer, pH7.5, 5mM magnesium chloride, 1mM thiamine pyrophosphate and 300mM 2-keto-L-gulonic acid, and the conversion rate is similar to that of Example 1 Ratio, increased by 16.9%, that is, 28.0g / L L-xylose was generated.

Embodiment 3

[0034] Basically the same as Example 1, the difference is that the reaction temperature is 45 ° C, 5mM magnesium chloride, 1mM thiamine pyrophosphate, 300mM 2-keto-L-gulonic acid, and the conversion rate is compared with Example 1, which has increased by 24.5 %, that is, 31.4g / L L-xylose was generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com