Ethylene propylene diene monomer rubber and preparation method thereof

A EPDM rubber, gel-like technology, applied in the chemical industry, can solve the problems of performance degradation and inability to use, and achieve the effect of good low temperature performance and excellent cold resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

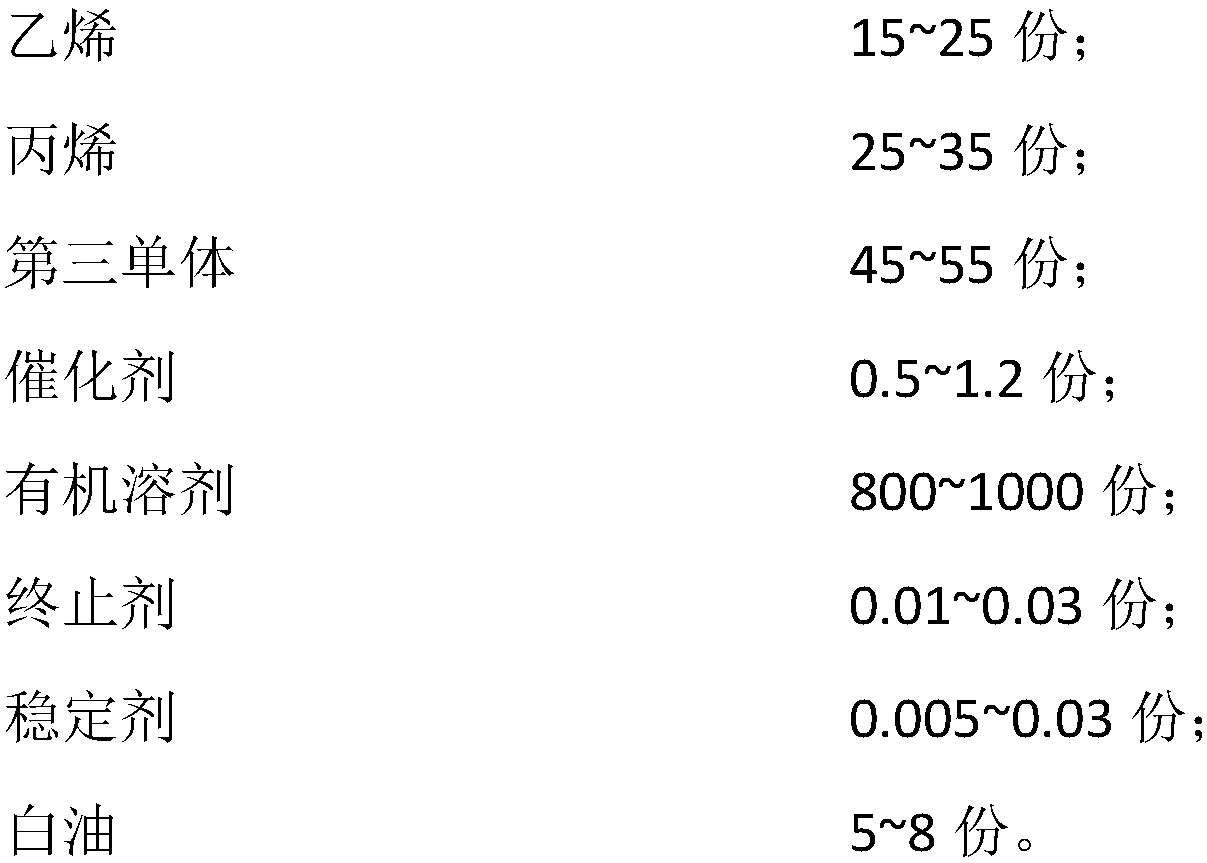

[0031] A kind of ethylene propylene diene monomer, comprises following composition by weight:

[0032]

[0033] The third monomer is ethylidene norbornene (ENB).

[0034] Described vanadium series catalyst is VOCl 3 , the alkylaluminum compound is trimethylaluminum, the activator is ethyl trichloroacetate, and the molar ratio between the alkylaluminum compound and the vanadium-based catalyst is 15; the activator and the vanadium-based The molar ratio of the catalyst was 4.

[0035] Described organic solvent is pentane.

[0036] The terminator is sodium dimethyl dithiocarbamate.

[0037] The stabilizer is tribasic lead sulfate.

[0038] A preparation method of EPDM, comprising the steps of:

[0039] (1) take each raw material according to weight component;

[0040] (2) Polymerization: Add the third monomer, catalyst, and organic solvent that have been weighed into the reaction kettle that has been replaced with nitrogen in advance, and after fully stirring, feed a mixe...

Embodiment 2

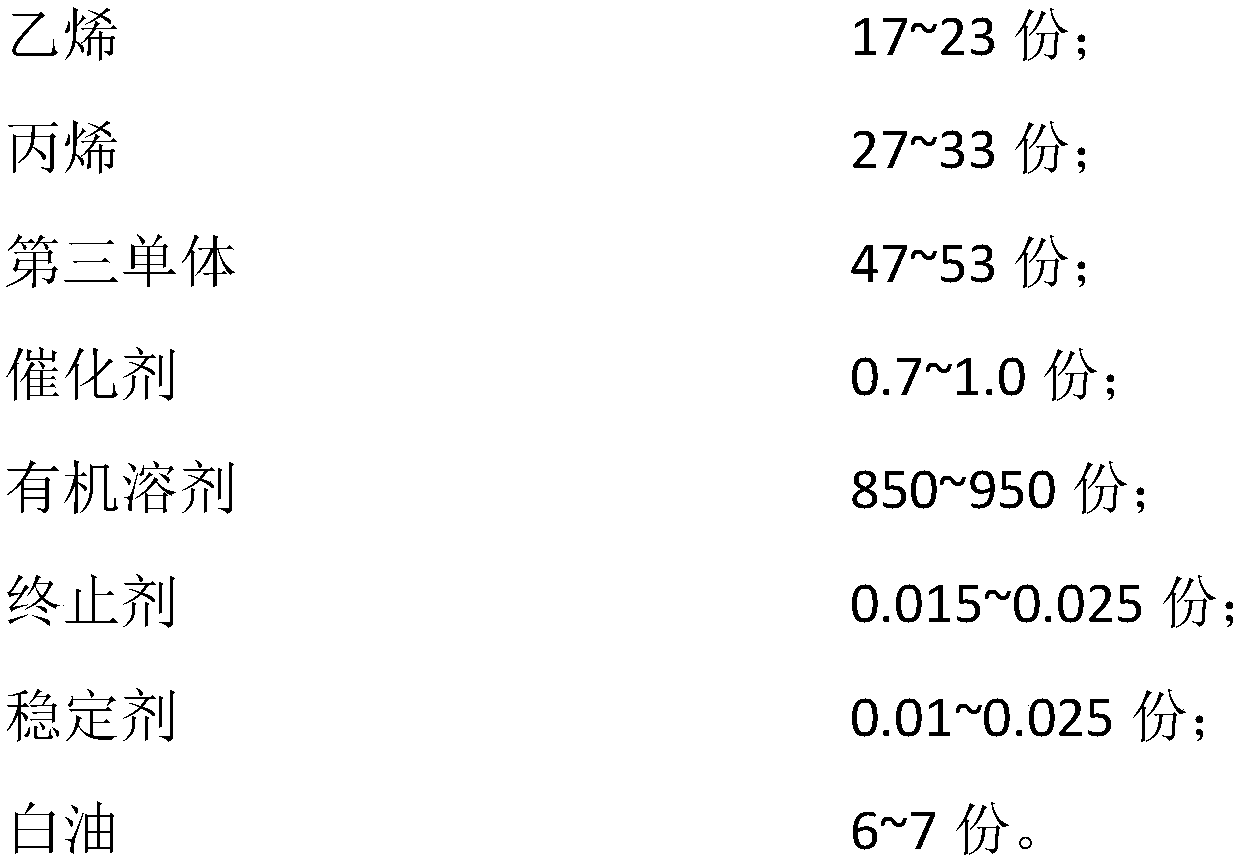

[0045] A kind of ethylene propylene diene monomer, comprises following composition by weight:

[0046]

[0047] The third monomer is dicyclopentadiene (DCPD).

[0048] Described vanadium series catalyst is VOCl 3 , the alkylaluminum compound is triethylaluminum, the activator is diethylchlorobenzenemalonate, and the molar ratio of the alkylaluminum compound and the vanadium catalyst is 40; the activation The molar ratio of agent to vanadium series catalyst is 8.

[0049] Described organic solvent is hexane.

[0050] The terminator is sodium polysulfide.

[0051] The stabilizer is lead dibasic phosphite.

[0052] A preparation method of EPDM, comprising the steps of:

[0053] (1) take each raw material according to weight component;

[0054](2) Polymerization: Add the third monomer, catalyst, and organic solvent that have been weighed into the reaction kettle that has been replaced with nitrogen in advance, and after fully stirring, feed a mixed gas of ethylene, propyl...

Embodiment 3

[0059] A kind of ethylene propylene diene monomer, comprises following composition by weight:

[0060]

[0061] The third monomer is 1,4-hexadiene (1,4-HD).

[0062] Described vanadium series catalyst is VOCl 3 , the alkylaluminum compound is trichlorodiethylaluminum, the activator is benzenesulfonyl chloride, and the molar ratio of the alkylaluminum compound to the vanadium catalyst is 20; the activator and the vanadium catalyst The molar ratio of the catalyst was 6.

[0063] Described organic solvent is heptane.

[0064] The terminator is sodium nitrite.

[0065] Described stabilizer is dibasic lead stearate.

[0066] A preparation method of EPDM, comprising the steps of:

[0067] (1) take each raw material according to weight component;

[0068] (2) Polymerization: Add the third monomer, catalyst, and organic solvent that have been weighed into the reaction kettle that has been replaced with nitrogen in advance, and after fully stirring, feed a mixed gas of ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com