Inverted type extruding foam pump

A foam pump and inverted technology, applied in the field of pump body structure, can solve the problems of reducing the service life of the foam pump, very high requirements for parts, and inability to deform, and achieves stable assembly difficulty, reduced processing difficulty, and low assembly difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

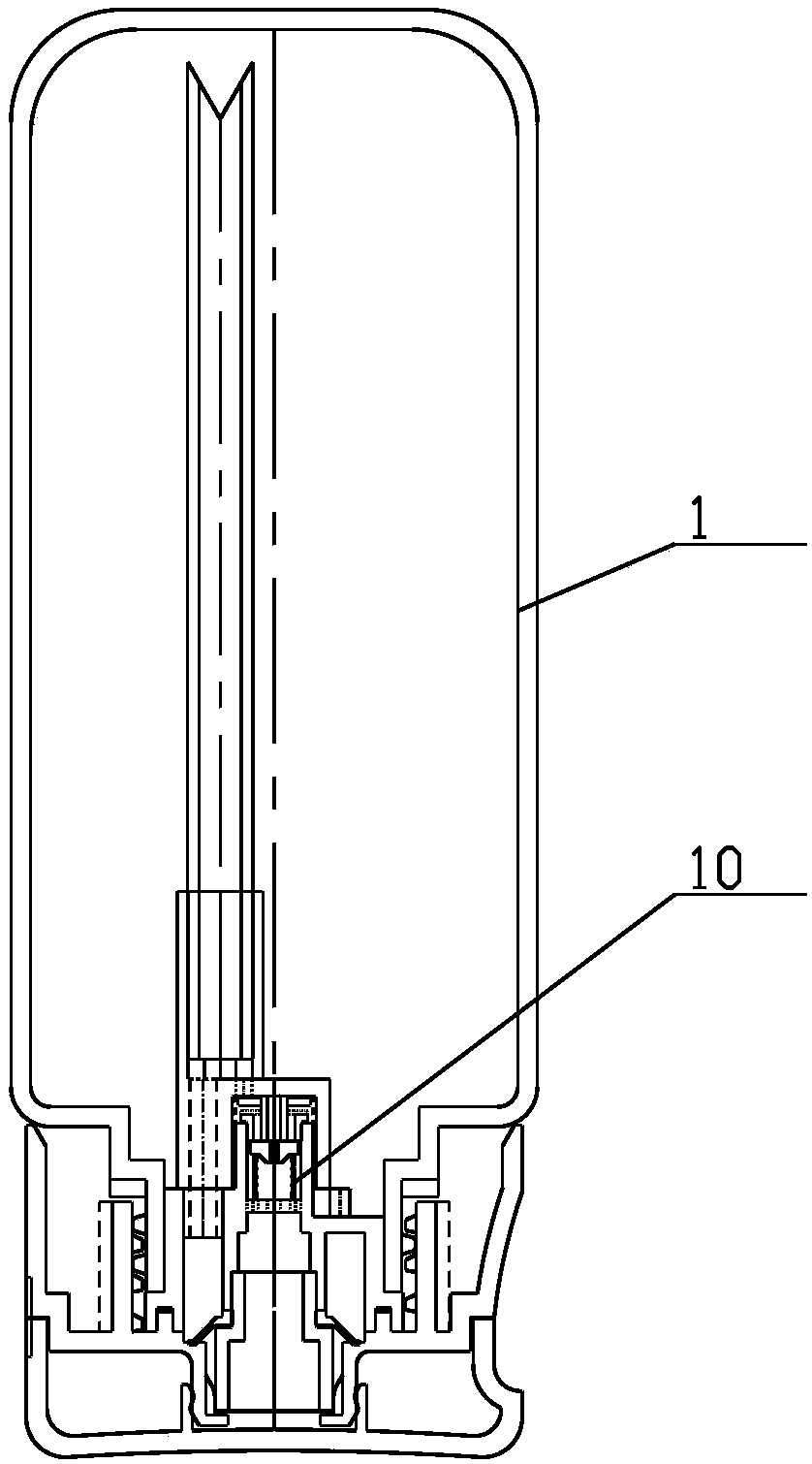

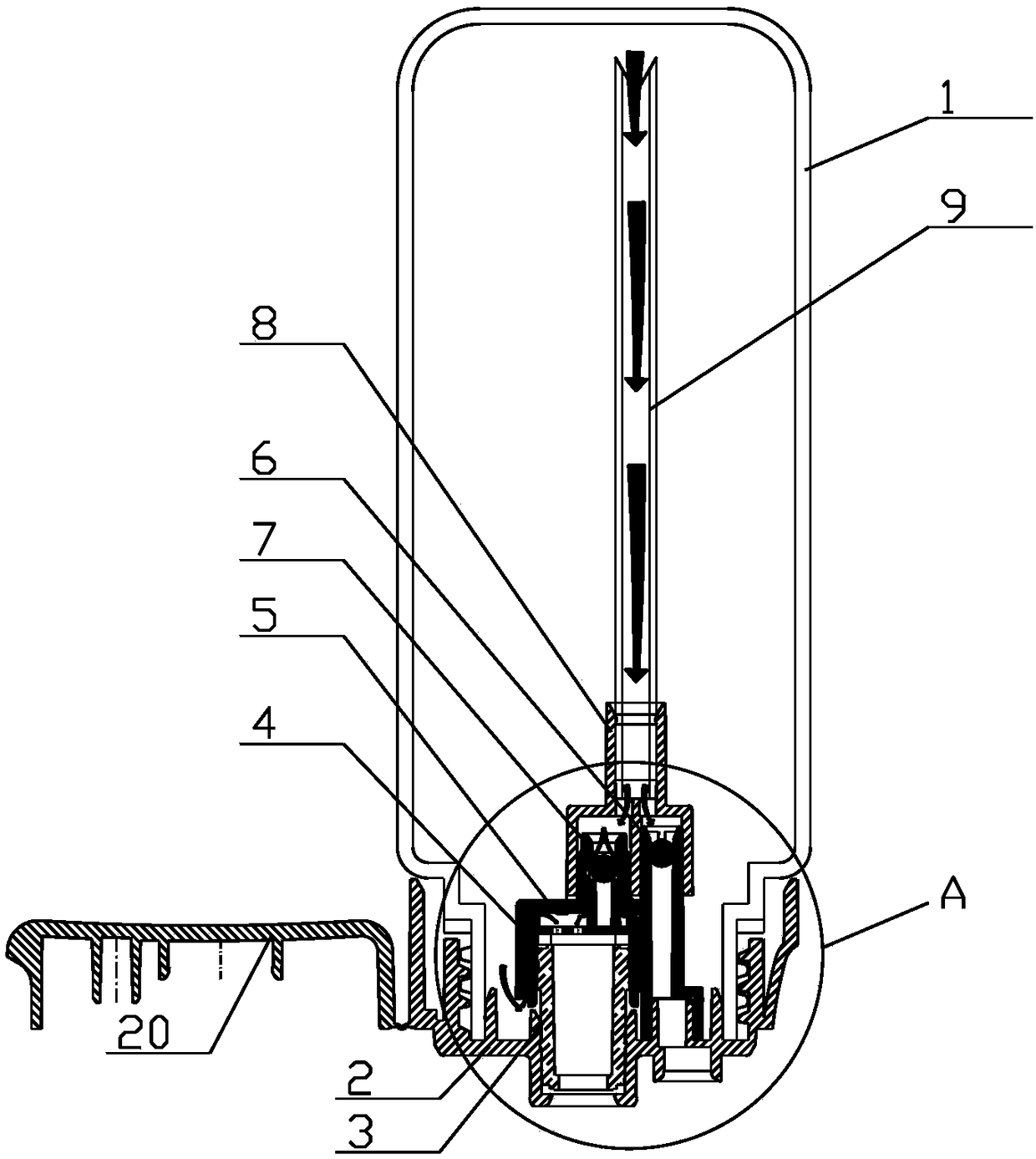

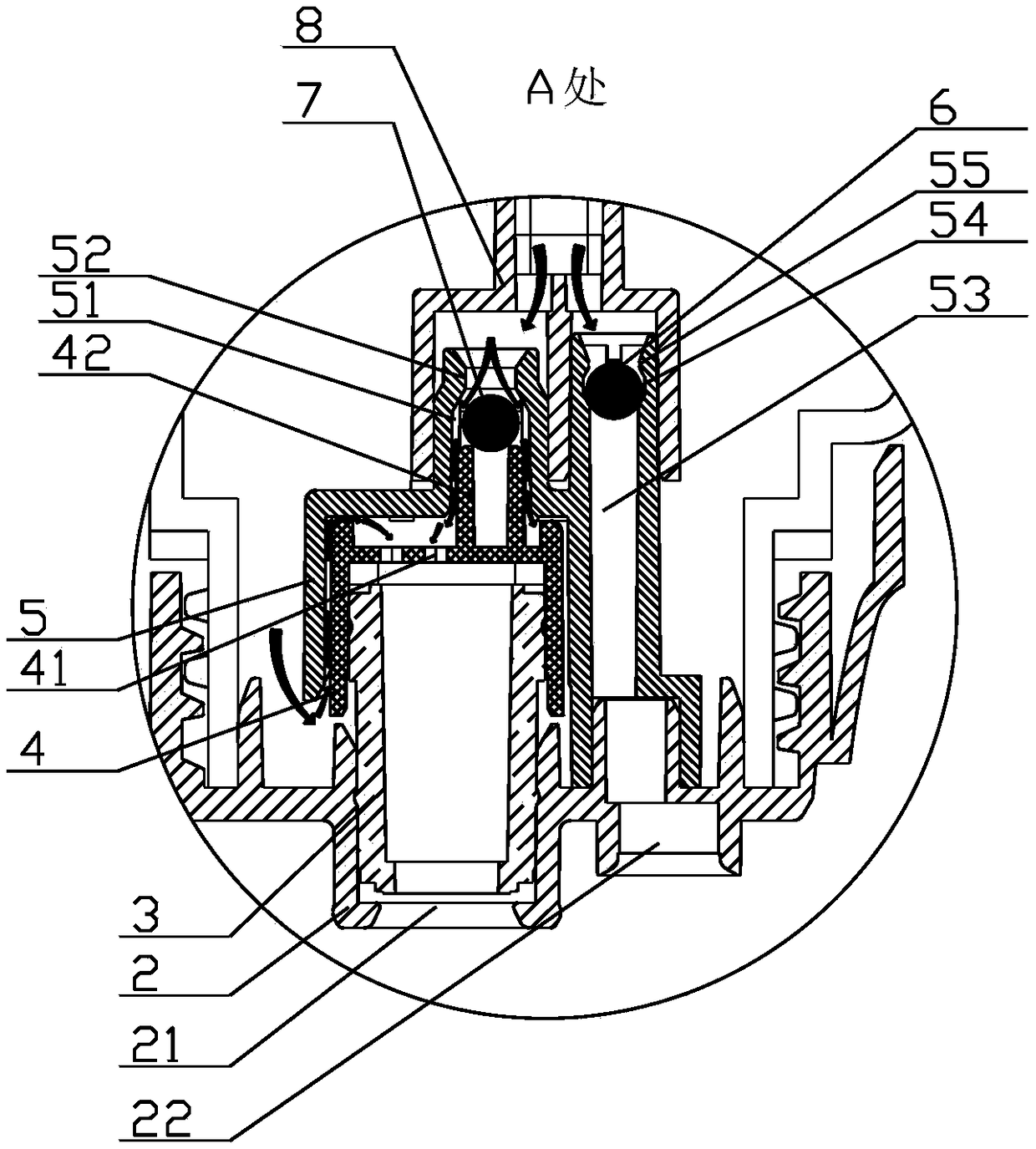

[0021] The present invention as Figure 1-7 As shown, it includes a bottle mouth seat 2, a netcom 3, a diverter valve 4, a valve seat 5, an air supply control ball 6, an air outlet control ball 7, a fixed seat 8 and a trachea 9, and the bottle mouth seat 2 is fixedly connected to the hand sanitizer. Liquid outlet hole 21 and external air supply hole 22 are provided on the bottom opening of squeeze bottle 1 for liquids such as detergent, detergent, etc., and in the bottle mouth seat 2;

[0022] The net 3 is fixedly connected in the outlet hole 21, the diverter valve 4 is fixedly connected inside the outlet hole 21, the diverter valve 4 covers the net 3, and the top of the diverter valve 4 is provided with at least one communication channel. Hole 41, the valve seat 5 is fixedly connected on the bottle mouth seat 2, and the said diverter valve 4 is empty; like this, when the user squeezes the squeeze bottle, the liquid in the bottle can first pass through the valve seat and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com