Manufacturing method for large-size seamless micro-nano soft mold

A manufacturing method and soft mold technology, which is applied in the field of manufacturing, can solve the problems such as the inability to realize the soft mold manufacturing of large-size non-splicing and accepting scale molds, and achieve the effects of low manufacturing cost, no splicing errors, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

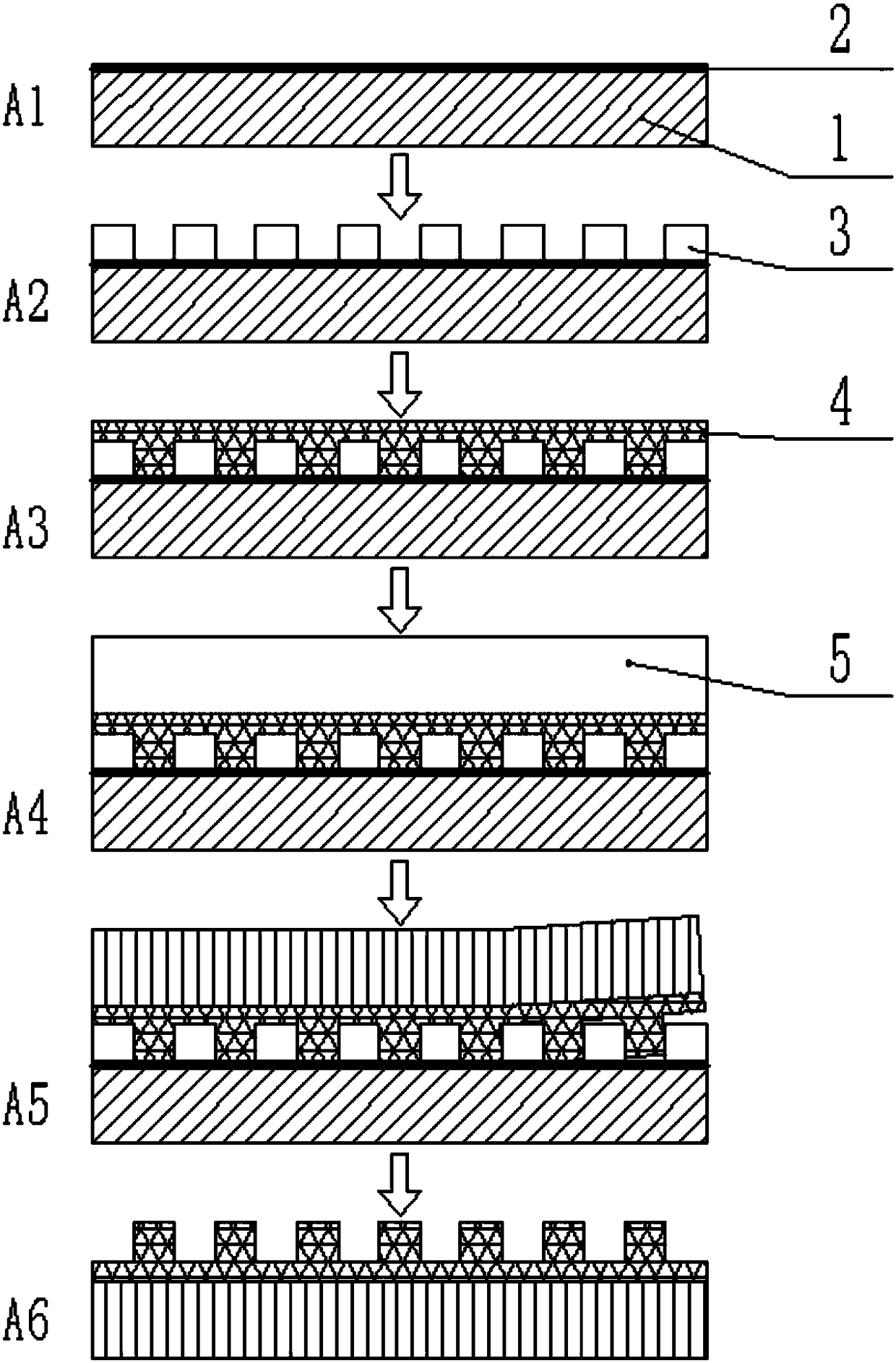

[0043] The present embodiment is used for the making of large-scale non-splicing composite soft mold, such as figure 1 As shown, the specific preparation steps are as follows:

[0044] (1) Substrate 1 pretreatment: A1 performs anti-adhesion treatment on glass substrate 1 to form anti-adhesion layer 2

[0045]Glass is used as the substrate 1, and the surface of the glass substrate 1 is subjected to anti-adhesion treatment. Firstly, the glass substrate 1 is cleaned, and deionized water is ultrasonically treated for 10 minutes; isopropanol is ultrasonically treated for 20 minutes; (FDTS), let it stand for 15 minutes; then, put the glass substrate 1 into it and soak for 30 minutes; then use isooctane, acetone, and isopropanol to clean each under ultrasonic conditions for 20 minutes; make the surface of the substrate 1 form an anti-adhesion layer 2 , and finally blow dry with nitrogen.

[0046] (2) Fabrication of sacrificial structure 3 by hot-melt electrohydrodynamic jet printi...

Embodiment 2

[0062] The specific preparation steps for the production of large-size non-splicing soft molds in this embodiment are as follows:

[0063] (1) Substrate 1 pretreatment

[0064] Glass is used as the substrate 1, and the surface of the glass substrate 1 is subjected to anti-adhesion treatment. Firstly, the glass substrate 1 is cleaned, and deionized water is ultrasonically treated for 10 minutes; isopropanol is ultrasonically treated for 20 minutes; (FDTS), let it stand for 15 minutes; then, put the glass substrate 1 into it and soak for 30 minutes; then use isooctane, acetone, and isopropanol to clean each under ultrasonic conditions for 20 minutes; make the surface of the substrate 1 form an anti-adhesion layer 2. Finally, blow dry with nitrogen.

[0065] (2) Fabrication of sacrificial structures by thermal fusion electrohydrodynamic jet printing 3

[0066] Using polycaprolactone (PCL) as the electrojet printing material, according to the micro-nano mold pattern structure t...

Embodiment 3

[0077] The specific preparation steps for the production of large-size non-splicing soft molds in this embodiment are as follows:

[0078] (1) Substrate 1 pretreatment

[0079] Glass is used as the substrate 1, and the surface of the glass substrate 1 is subjected to anti-adhesion treatment. Firstly, the glass substrate 1 is cleaned, and deionized water is ultrasonically treated for 10 minutes; isopropanol is ultrasonically treated for 20 minutes; (FDTS), let it stand for 15 minutes; then, put the glass substrate 1 into it and soak for 30 minutes; then use isooctane, acetone, and isopropanol to clean each under ultrasonic conditions for 20 minutes; make the surface of the substrate 1 form an anti-adhesion layer 2 , and finally blow dry with nitrogen.

[0080] (2) Fabrication of sacrificial structures by thermal fusion electrohydrodynamic jet printing 3

[0081] Using polycaprolactone (PCL) as the electrojet printing material, according to the micro-nano mold pattern structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com