3D printer

A 3D printer and print head technology, applied in the field of 3D printing, can solve the problems of pulling raw materials, affecting printing, and high cost, and achieve the effects of cost reduction, energy saving, constant temperature performance, and small high-temperature area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

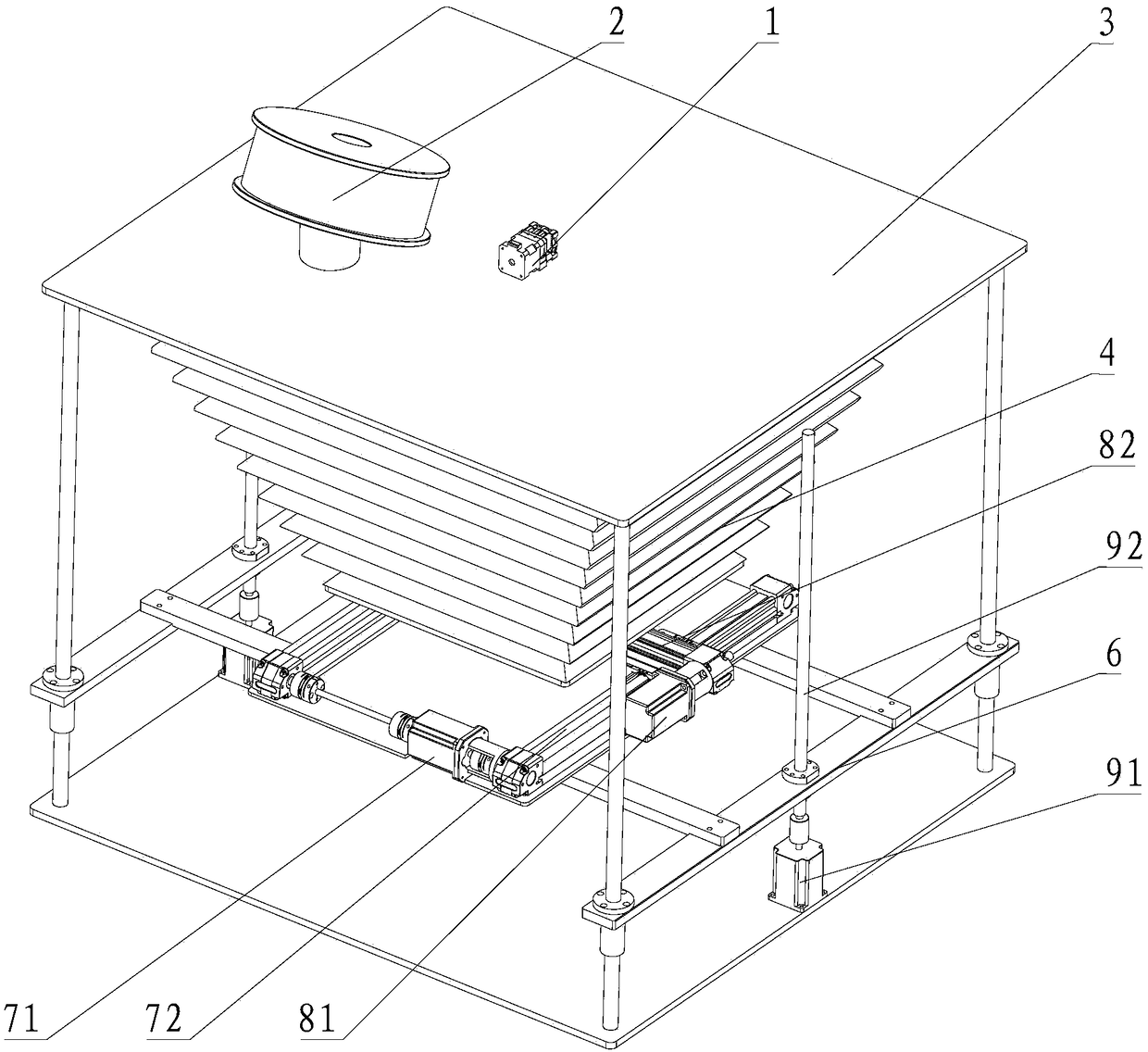

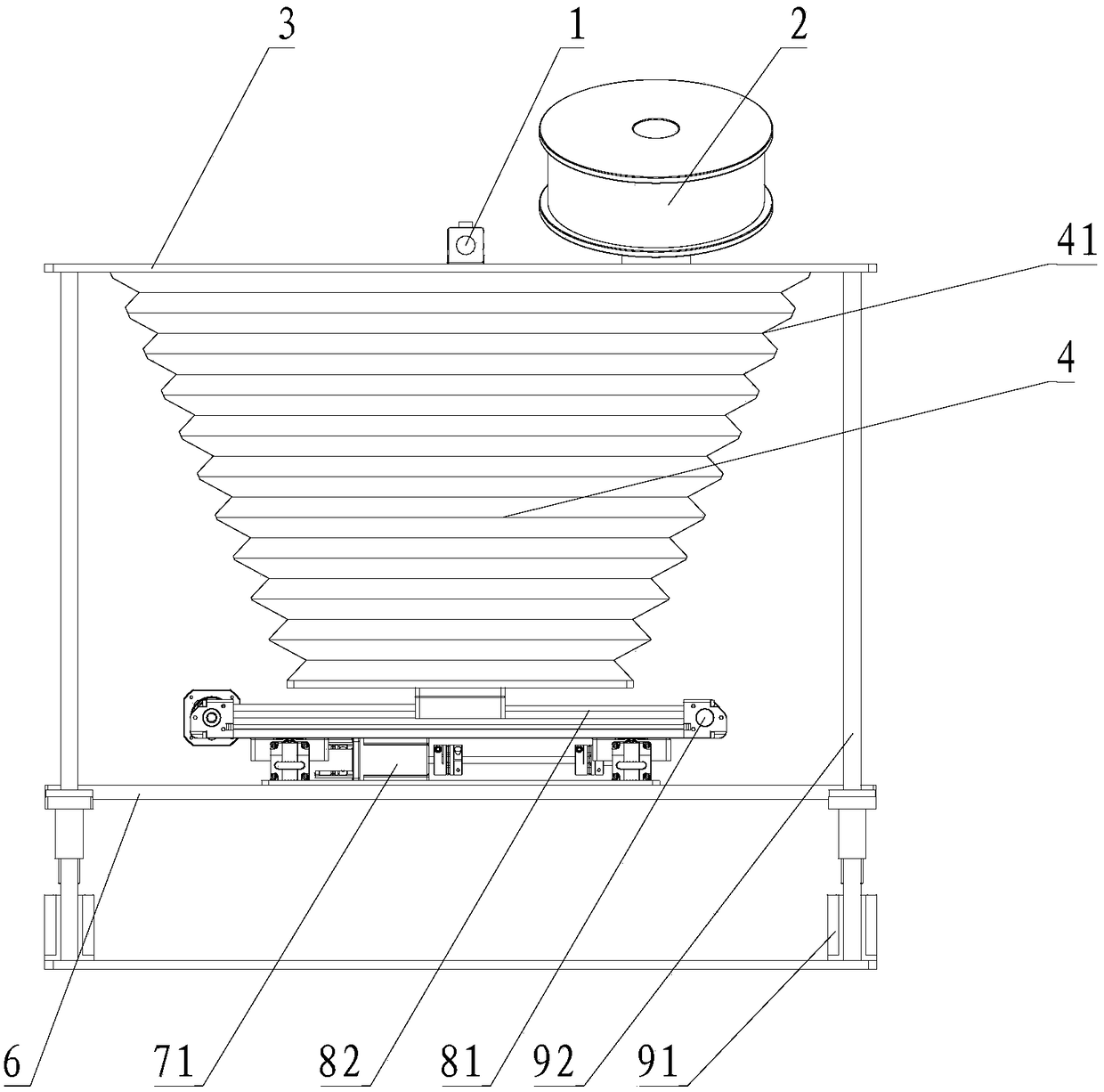

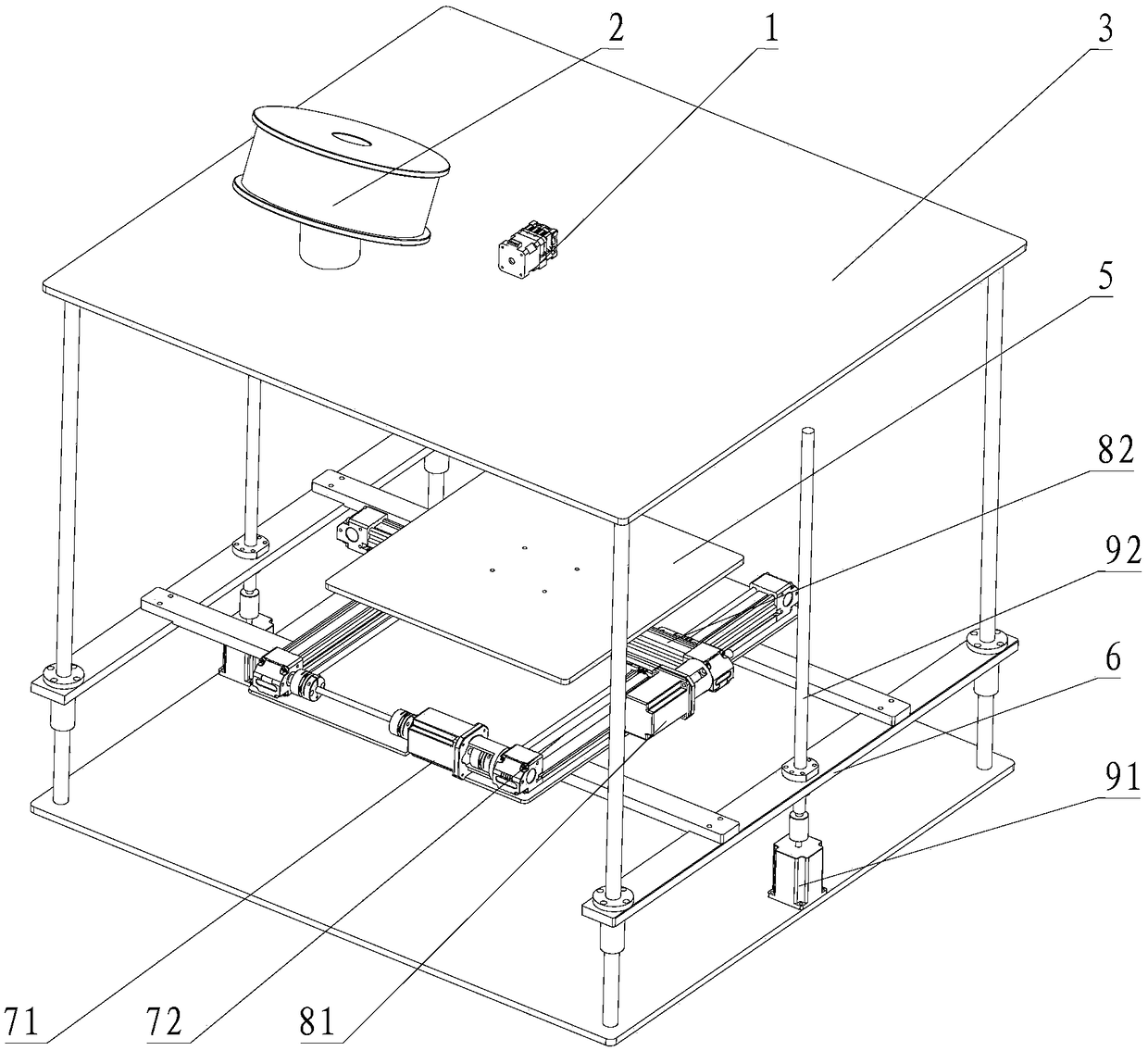

[0038] Please refer to Figure 1-4 , Embodiment 1 of the present invention is:

[0039] A 3D printer, comprising a printing head 1, a raw material tray 2, a cover plate 3, a heat shield 4, a printing platform 5, a lift table 6, an X-axis motor 71, an X-axis slide rail 72, a Y-axis motor 81, and a Y-axis slide Rail 82, Z-axis motor 91 and Z-axis slide bar 92;

[0040] The print head 1 and the raw material tray 2 are respectively arranged on the upper surface of the cover plate 3, the cover plate 3 is arranged parallel to the printing platform 5, and the printing platform 5 is arranged below the cover plate 3, and the print head 1 The discharge nozzle 11 passes through the cover plate 3 and faces the printing platform 5;

[0041] The heat shield 4 is a hollow structure with openings at both ends, the material of the heat shield 4 is silica gel, and the heat shield 4 is an inverted terrace structure;

[0042] One end of the heat shield 4 is connected to the lower surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com