Adjustable-type supporting cutting system and method for furniture producing wood bars

A cutting system and adjustable technology, applied in wood processing equipment, manufacturing tools, sawing equipment, etc., can solve the problems of inability to obtain products of multiple lengths, lack of dust treatment devices, unsafe feeding, etc., to achieve the goal of feeding Convenience and safety, convenient dust removal, and the effect of avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

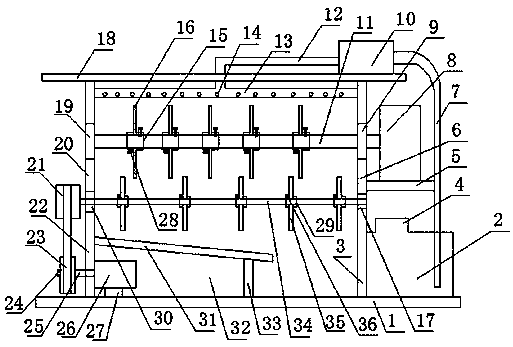

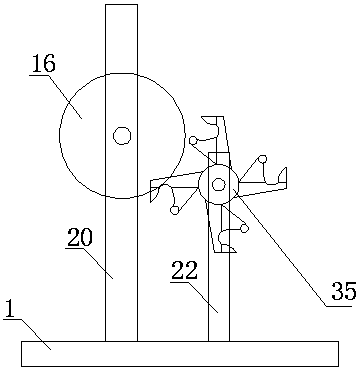

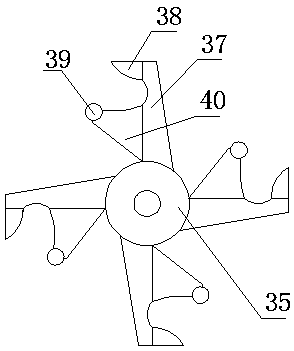

[0019] Such as figure 1 , figure 2 The adjustable support and cutting system for wood bars in furniture production includes an installation base 1, and the left and right sides of the upper part of the installation base 1 are respectively provided with a left feeding support column 22, a left cutting support column 20, a right loading support column 3 and a right cutting support column 6. The left cutting support column 20 and the right cutting support column 6 are respectively arranged at the rear positions of the left loading support column 22 and the right loading support column 3; Axle 34; The middle position of feeding shaft 34 is provided with a plurality of feeding shaft sleeves 29, and the outer circumference of feeding shaft sleeve 29 is fixedly connected with feeding support plate 35; the side of feeding shaft sleeve 29 is provided with Feeding shaft sleeve fixed stud 36 is fixed; Feeding shaft 34 left ends are fixedly provided with driven wheel 21; Cutting bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com