A robot joint driver

A technology of robot joints and drivers, applied in the field of robots, can solve the problems of large space occupation, difficult precise control, complex structure, etc., and achieve the effects of protecting cleanliness, facilitating precise control, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

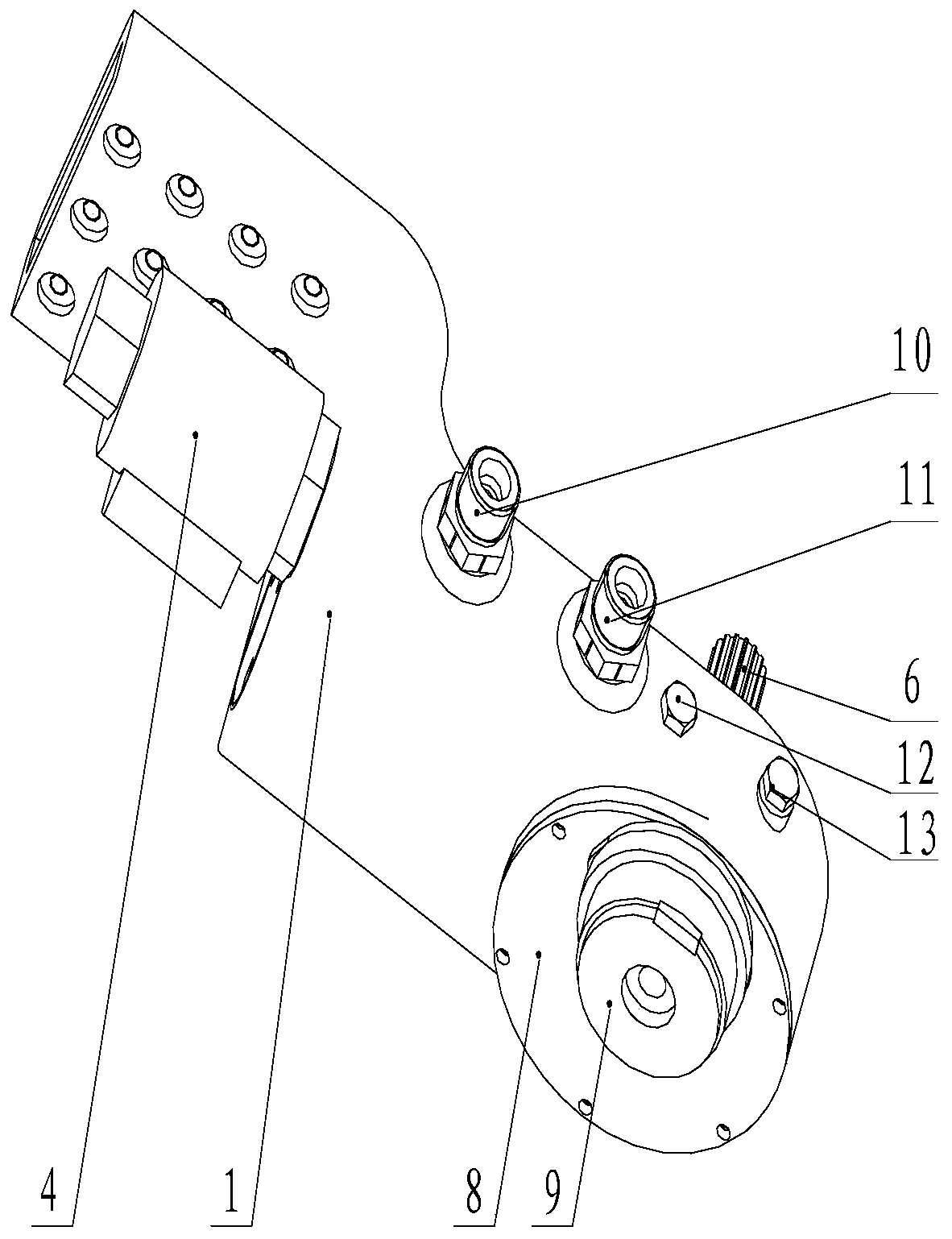

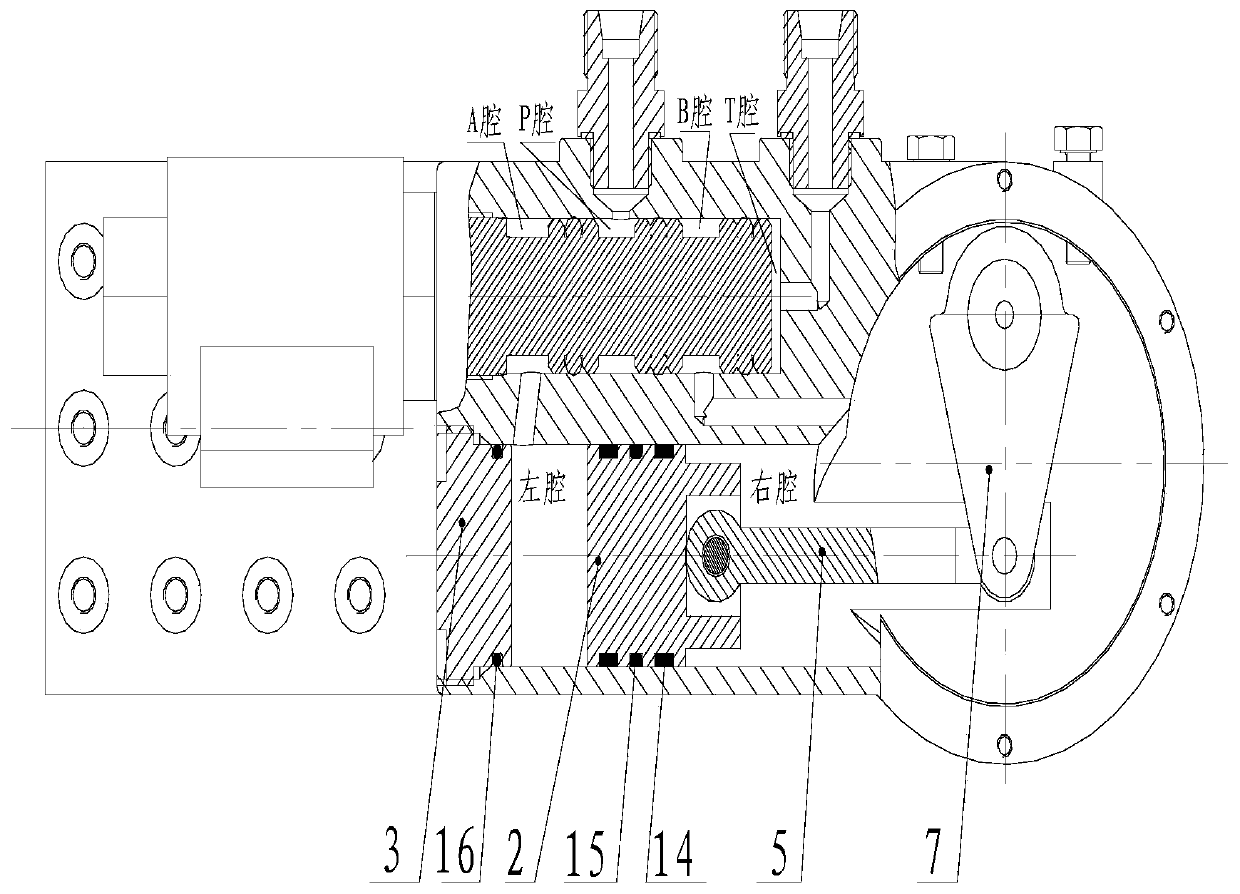

[0044] The invention provides a robot joint driver, such as figure 1 and 2 As shown, it includes housing 1, piston 2, screw plug 3, three-position four-way valve 4, connecting rod 5, rotating shaft 6, crank 7, cover plate 8, encoder 9, pipe joint A10, pipe joint B11, and adjustment screw A12, adjusting screw B13, wear ring 14, lattice ring 15, O-ring 16.

[0045] The three-position four-way valve 4 controls the hydraulic oil to drive the piston 2 to reciprocate, and the piston 2 drives the rotating shaft 6 to rotate through the connecting rod 5 and the crank 7, and the rotating shaft 6 is connected with the corresponding driving parts of the robot.

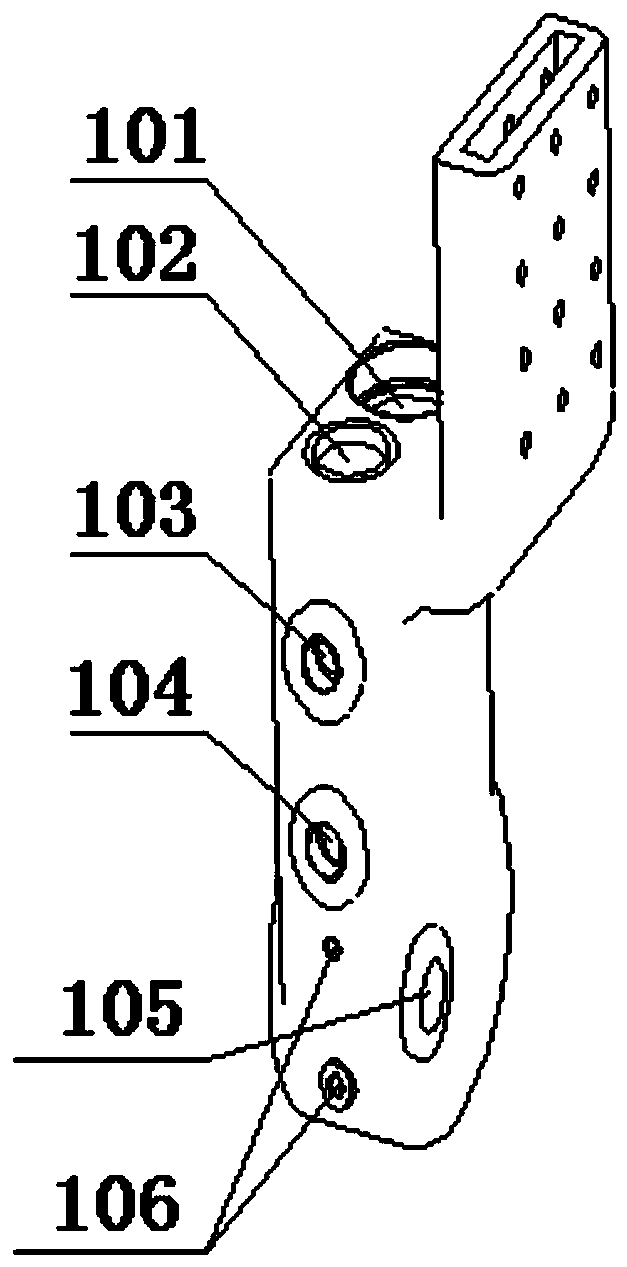

[0046] Such as image 3 As shown, the housing 1 includes a first section with a piston mounting hole 101, a valve hole 102, a P port 103, a T port 104, a rotating shaft mounting hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com