Grinding work station and method for generating machining tracks thereof

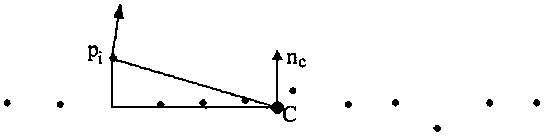

A workstation and trajectory technology, which is applied in the direction of metal processing equipment, grinding machine parts, workpiece feed movement control, etc., can solve the problems of complex grinding trajectory, long debugging cycle, and high technical requirements for debugging personnel, so as to improve vector information The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

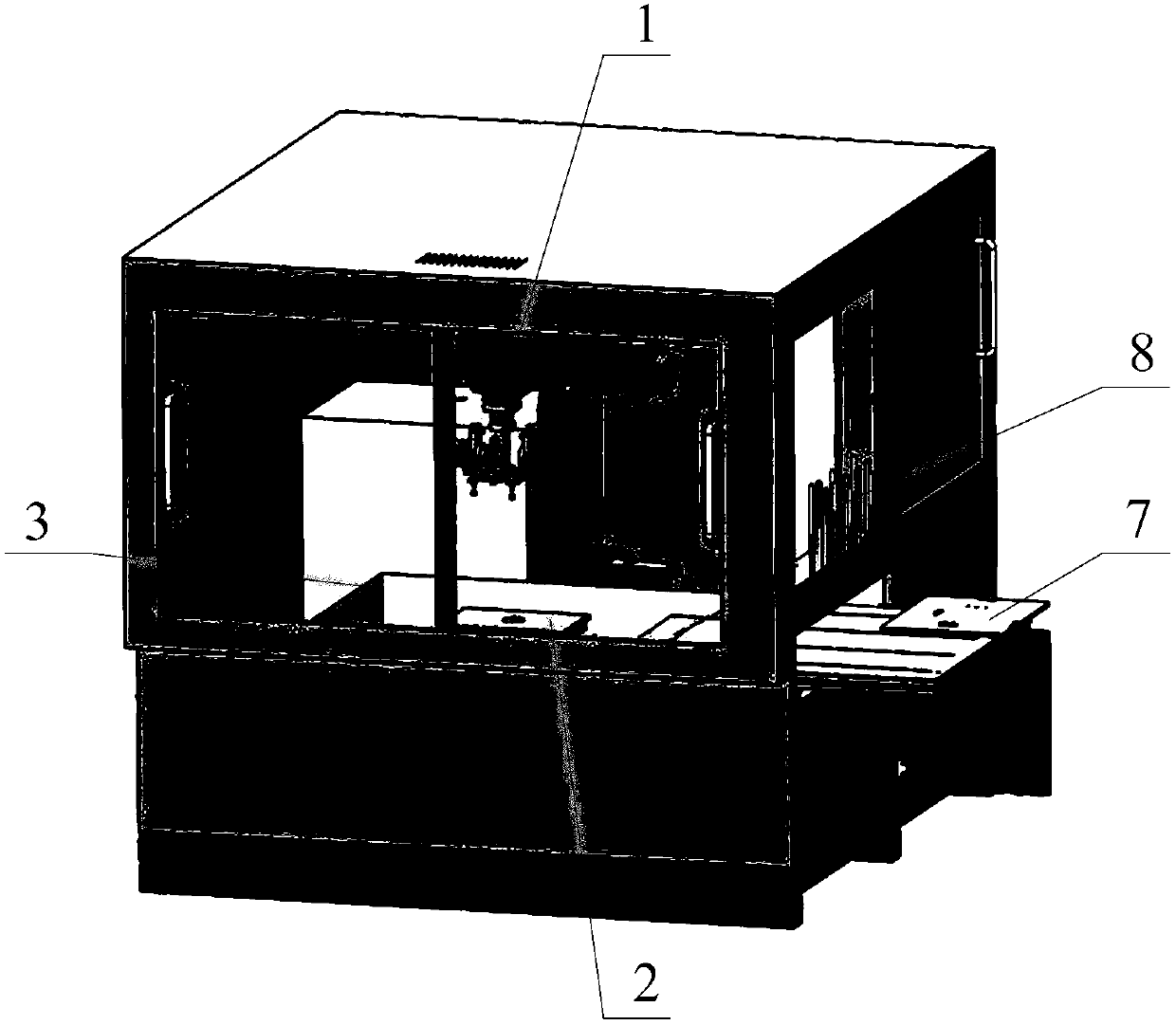

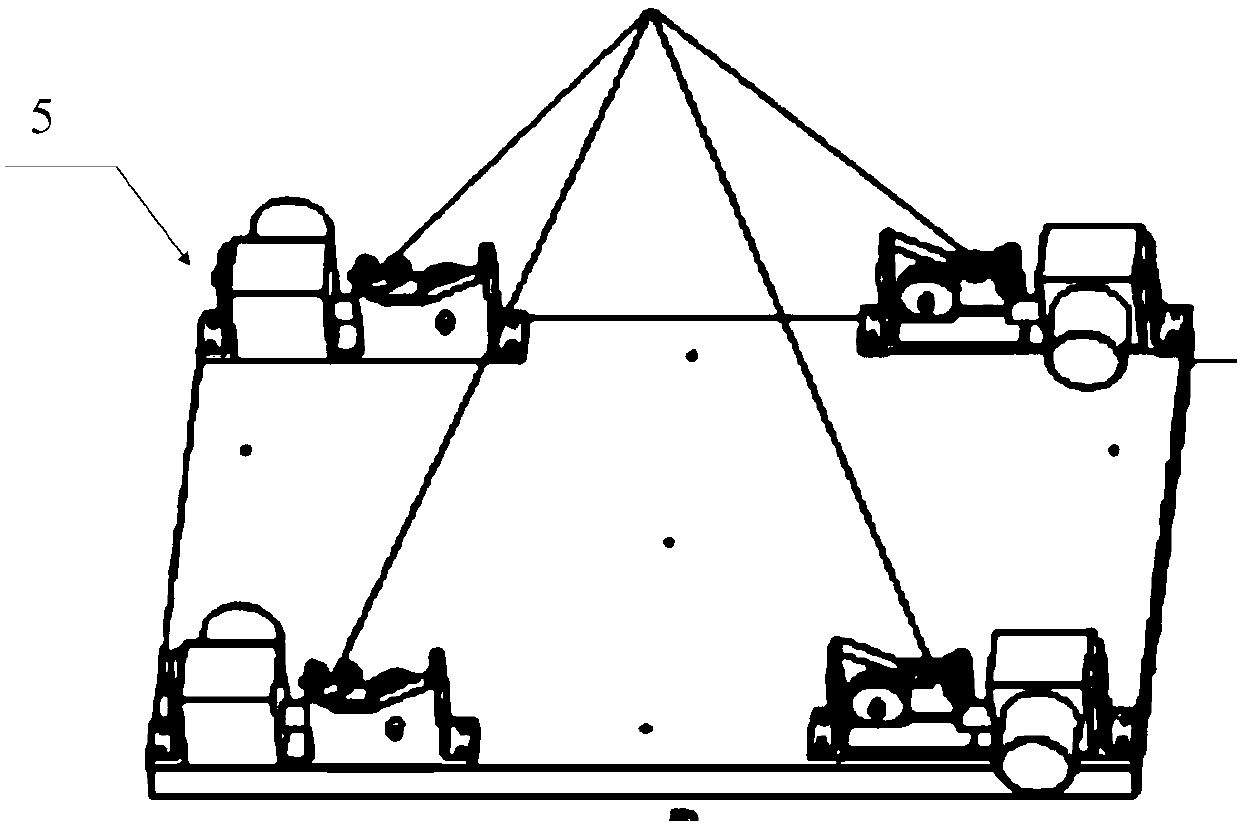

[0063] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a grinding workstation, which includes: a grinding robot 1, a grinding head 2, a water tank 3, a processor, four calibration devices 4, four measuring devices 5 and a guide 6, The grinding head is arranged at the end of the arm of the polishing robot 1, the water tank 3 is arranged below the grinding head, the jig 2 is arranged in the water tank 3, and the four calibration devices 4 are all arranged On the processing surface of the jig 2, the water tank 3 is quadrilateral, and the four measuring devices 5 are respectively installed at the four corners of the water tank 3, and the processor communicates with the four measuring devices respectively. The equipment 5 is connected to the polishing robot 1, and each of the measuring equipment 5 includes: a first wire sensor 51 and a second wire sensor 52, the tails of the first wire sensor 51 and the second wire sensor 52 pass through a r...

Embodiment 2

[0074] Such as Figure 4 As shown, on the basis of Embodiment 1, the first wire pull sensor 51 in this embodiment also includes: a calibration head 511, a wire clamping groove 512, a large wire pulley 513, a small wire pulley 514, and a clamping device 515. The calibration head 511 is arranged on the head of the first pull wire sensor 51, one end of the calibration head 511 is provided with a hook 54, and the other end of the calibration head 511 is connected to the first wire sensor 51 through a pull wire; The large guiding wheel 513 and the small guiding wheel 514 are arranged on one side of the first cable sensor 51, the large guiding wheel 513 is adjacent to the head of the first cable sensor 51, and the small guiding wheel 514 is adjacent to the The tail portion of the first cable sensor 51, the large guide wheel 513 is used to coil the cable, and the small guide wheel 514 is used to tension the cable; the head of the first cable sensor 51 is provided with a clamping groo...

Embodiment 3

[0078] Such as image 3 , Figure 5 as well as Figure 6 As shown, on the basis of Embodiment 2, the second cable sensor 52 and the first cable sensor 51 of this embodiment have the same structure, and are connected by a rotating shaft, and an angle sensor is arranged in the rotating shaft, which can measure the The angle between the first pull wire sensor and the second pull wire sensor, the first pull wire sensor 51 and the clamping device 515 of the second pull wire sensor 52 are respectively arranged on adjacent side walls of the water tank 3 , The first pull wire sensor and the second pull wire sensor can rotate around a fixed shaft, so the corner between the first pull wire sensor 51 and the second pull wire sensor 52 and the clamp between the adjacent two side walls in the water tank 3 same angle.

[0079] Measuring equipment 5 is set on the water tank 3, so that the simulated processing trajectory generated by the guide 6 is closer to the processing trajectory of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com