Fine copper pipe straightening device

A straightening device and straightening technology, applied in the field of mechanical processing, can solve the problems of poor straightening effect and detachment of thin copper pipes, and achieve the effects of reducing settings, simplifying structure and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further detailed explanation through specific implementation mode below:

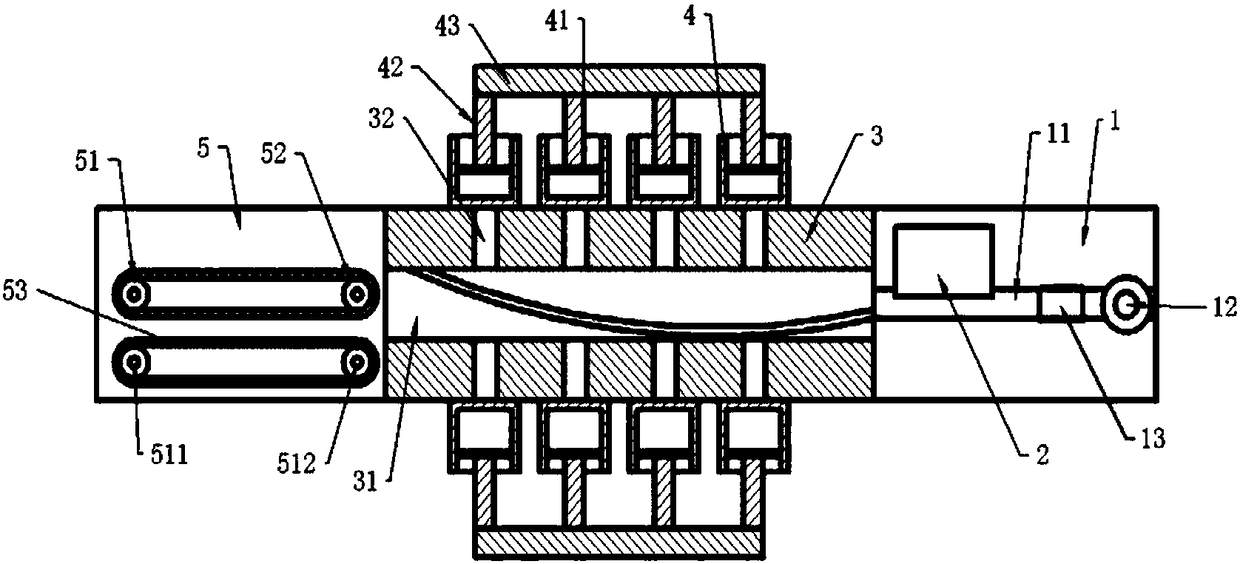

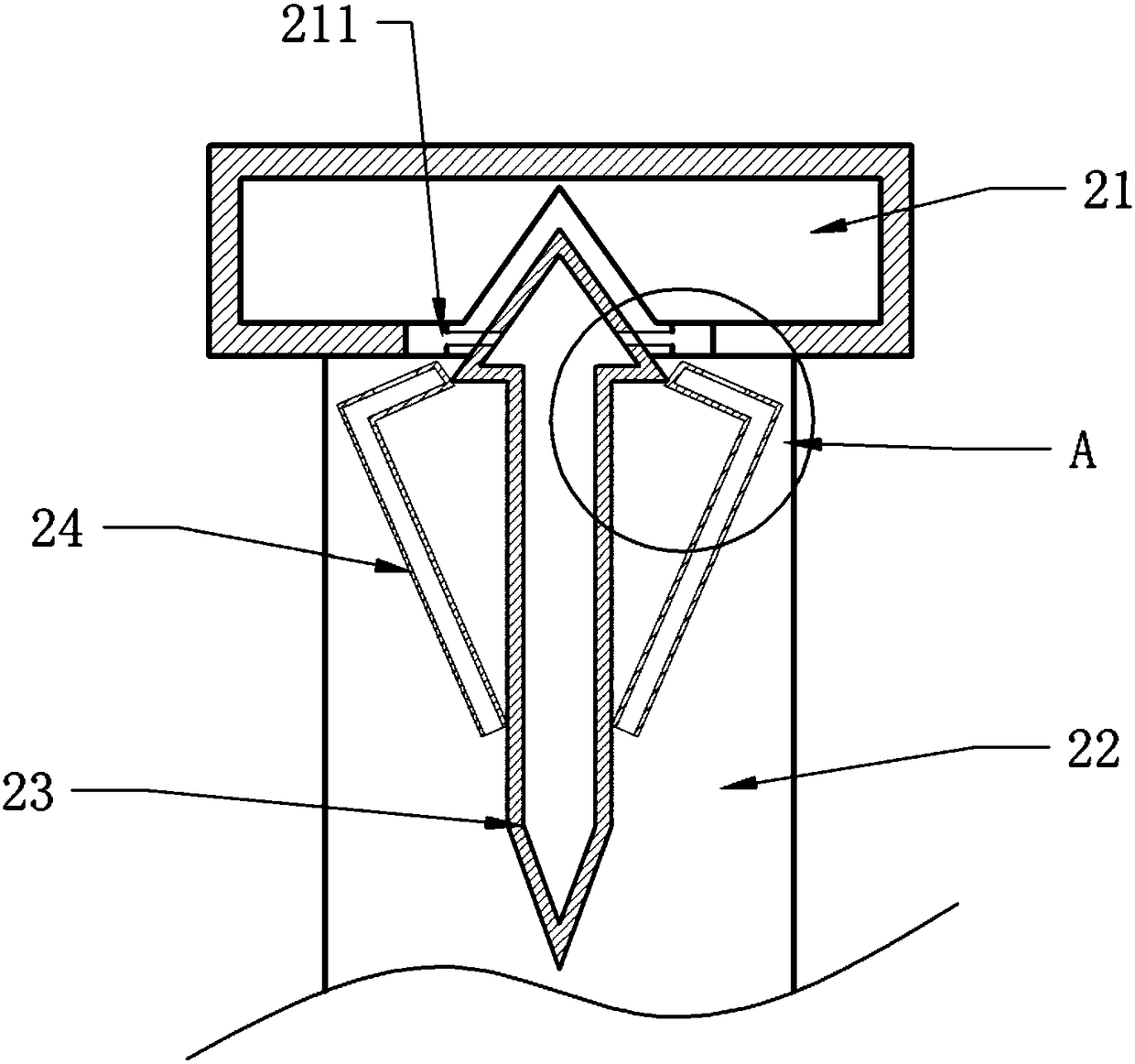

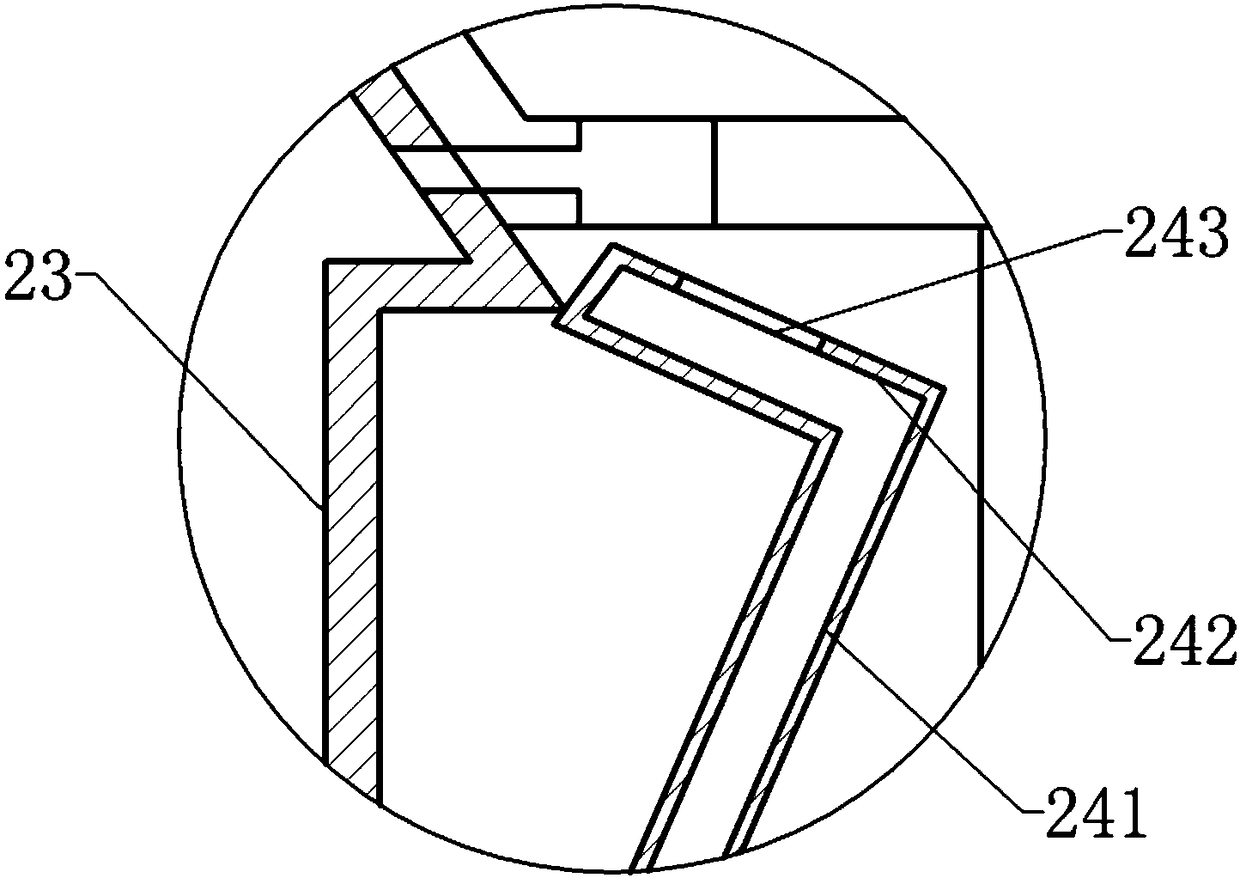

[0032]The reference signs in the drawings of the description include: cutting table 1, conveying groove 11, winding roller 12, limit roller 13, cutting mechanism 2, air storage box 21, air outlet 211, knife rest 22, cutting knife 23, guide Tuyere 231, air guide pipe 24, vertical pipe 241, horizontal pipe 242, air inlet 243, straightening table 3, straightening groove 31, through hole 32, gas storage bin 4, piston 41, push rod 42, connecting rod 43, support Platform 5, driving wheel 51, first rotating shaft 511, driven wheel 52, second rotating shaft 521, belt 53, first connecting rod 6, second connecting rod 7, third connecting rod 8, sliding block 9.

[0033] The embodiment is basically as attached figure 1 Shown:

[0034] A thin copper tube straightening device, including a cutting table 1, a straightening mechanism and a shaping mechanism arranged in sequence from left to right, and a wire w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com